Beginner’s Guide to Woodworking Terms

Do you know these basic woodworking terms? Grow your woodshop vocabulary with these common words used in DIY plans and get the free printable for your shop!

Woodworking Words You Need to Know

There are many terms unique to woodworking. Those words can be intimidating if you’re unsure of their meaning. This post will serve as a glossary for all of those terms and ensure your DIY project is a complete success.

You may also enjoy 10 Tools Beginners Need to Start Woodworking and 11 Places to Take Beginner Woodworking Classes

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Before we look at the common woodworking terms, be sure to click the subscribe button at the bottom of this page to sign up for my FREE weekly newsletter loaded with helpful pocket hole tricks, space-saving workshop ideas, clever DIY tips and more!

Beginner’s Guide to Woodworking Terms

1x Material (1×3, 1×4, 1×6, etc.)

One by material like a 1×4 (spoken as one by four) is a piece of wood often used to build DIY furniture.

Let’s look a little closer at a 1x4x8. The first number refers to the thickness. The thickness of a 1x4x8 is ¾ inches. The second number refers to the width. The width of a 1x4x8 is 3-½ inches. The third number refers to the length. The length of a 1x4x8 is 8 feet.

2x (2×2, 2×4, etc.)

Two by material like a 2×4 (spoken as two by four) is a piece of wood often used to build DIY furniture.

Let’s look a little closer at a 2x4x8. The first number refers to the thickness. The thickness of a 2x4x8 is 1-1/2 inches. The second number refers to the width. The width of a 2x4x8 is 3-½ inches. The third number refers to the length. The length of a 2x4x8 is 8 feet.

The edges of two by material is round or curved. Many times a table saw is used to rip or remove the round corners before using it to build projects.

5/4 Lumber

5/4 lumber (spoken as five-quarter) is a piece of wood that is sometimes used to build DIY furniture.

Let’s look a little closer at a 5/4x4x8. The first number refers to the thickness. The thickness of a 5/4x4x8 can range from about 1 inch to 1-¼ inches thick. Many times the 5/4 lumber I use measures 1-⅛ inches thick. The second number refers to the width. The width of a 5/4x4x8 is 3-½ inches. The third number refers to the length. The length of a 5/4x4x8 is 8 feet.

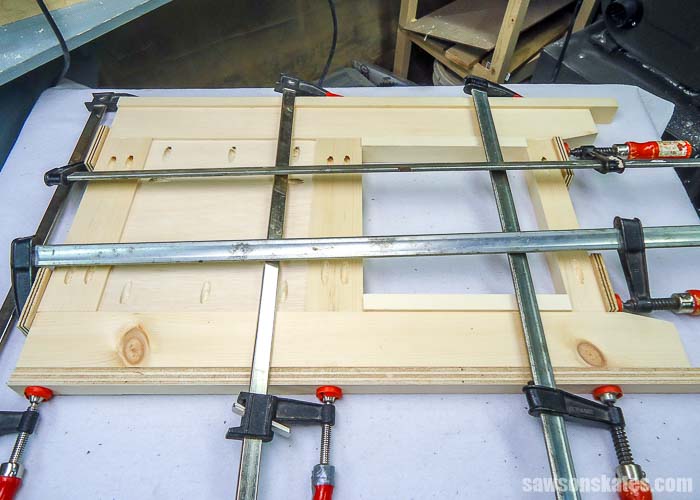

Bar Clamp

A bar clamp has a metal bar with a fixed jaw on one end. There is an adjustable jaw on the other end. A handle on the adjustable end tightens the clamp.

Bevel Cut

A bevel cut is an angled cut made on the edge of a board. A bevel cut changes the profile of the wood.

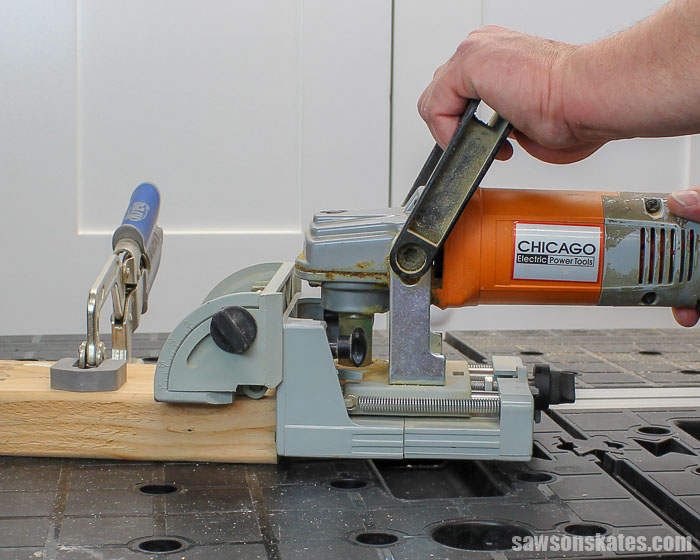

Biscuit Joiner

A biscuit joiner or plate joiner has a small horizontally mounted saw blade. When the biscuit joiner is pushed into a workpiece the blade cuts a half-moon shaped slot. Then the biscuit joiner is positioned on the corresponding workpiece and the blade is pushed into the workpiece which cuts the second half of the slot.

Glue is applied to a thin football-shaped wafer called a biscuit. The biscuit is placed into the slots and the joint is clamped until the glue dries.

A biscuit joiner can cut three sizes of slots. The smallest biscuit is “0”, the medium size biscuit is “10” and “20” is the largest biscuit. The “0” and “10” biscuits might be used for smaller joints like joining a rail to a stile. A “20” biscuit might be used for edge joints to join boards to form a tabletop.

Related: Kreg Jig vs Biscuit Joiner: Differences of Pocket Holes and Biscuit Joints

Butt Joint

A butt joint joins the end of one workpiece to the edge of another workpiece. Common uses for butt joints are frames and doors.

Caul

A caul or clamping caul has two functions. First, it helps provide equal clamping pressure to the parts that are being clamped. Second, it protects the wood of our projects from being dented while the parts are being clamped. Cauls are often pieces of scrap wood inserted between the clamp and our project.

Related: 6 Tips to Clamp Your DIY Project Like a Pro

Circular Saw

A circular saw is a hand-held tool with a rotating blade used for cutting wood.

Related: 4 Ways to Make Straight Cuts with a Circular Saw

Clamp

To hold workpieces in place while glue is drying or fasteners like nails or screws are driven.

Countersink

A countersink drill bit has two functions. First, it drills a pilot hole into the workpiece. A pilot hole is a small hole drilled into a workpiece that creates a space for a fastener like a screw. Drilling a pilot hole helps to prevent cracking or splitting the workpiece.

Second, a countersink drill bit creates a “V” or countersink in the face of a workpiece. This “V” or recessed area allows a screw with a countersunk head to be driven flush with the face of the workpiece.

I often use countersink bits because they give my projects a neat, professional look.

Related: How to Use a Countersink Bit

Crosscut

A crosscut or simply a cut is made at a 90-degree angle across the grain of the wood or across the width of a board.

Related: Kreg Crosscut Station: How to Use and Review

Dado

A dado is a groove cut across the grain of a workpiece. A groove is cut with the grain of a workpiece.

A dado can be cut with a dado blade and a table saw or a straight bit installed in a router.

Drill

Wikipedia defines a drill as “a tool primarily used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver, depending on application, secured by a chuck.”

Related: Beginner’s Guide to Using a Power Drill

Edge Joint

An edge joint joins the edges of two boards. Common uses for edge joints are panels and tabletops.

Related: Need to Know Pocket Hole Tips for Edge Joints

End Grain

End grain is the growth ring pattern of wood that can be seen on the end of a board.

Forstner Bit

A Forstner bit drills holes with smooth, clean sides and flat bottoms. I often use countersink bits because they give my projects a neat, professional look.

Related: How to Change a Drill Bit

Kreg Jig

A Kreg Jig or pocket hole jig is an easy way for both beginners and advanced DIYers to join pieces of wood together.

Related: 9 Pocket Hole Mistakes You Don’t Want to Make and How to Use a Kreg Jig

Miter Cut

A miter cut is made at an angle across the grain of the wood or across the width of a board.

Related: 7 Miter Saw Tricks Every DIYer Should Know

Miter Joint

A miter joint joins two workpieces cut at angles.

Related: How to Join Miters with Pocket Holes

Miter Saw

A miter saw has an overhead mounted saw blade. The wood to be cut, or the workpiece, is placed on the table and against the fence. The saw blade is lowered to make the cut and then released to return to its original position.

Related: How to Adjust a Miter Saw for Accurate Cuts and How to Change Blade on Miter Saw

Plywood

Plywood is a wood panel made of layers of thinner wood. The layers are glued together to form a panel. Plywood is sometimes called sheet goods.

Pocket Hole

A pocket hole is created by a pocket hole jig or Kreg Jig. It’s an angled hole in a workpiece.

Pocket Screw

A pocket screw is used to join a workpiece with a pocket hole to a second workpiece. Pocket screws have a smooth upper shank and a flat washer head.

The smooth upper shank allows the pocket screw to slide through the pocket hole and join the workpieces tightly together.

The flat washer head design of a pocket screw seats perfectly against the flat bottom of the pocket hole and pulls the two workpieces together.

There are two types of pocket screws. Fine-thread pocket screws are designed to be used with hardwoods like oak, maple, and poplar.

Coarse-thread pocket screws are designed to be used with softwoods like pine, plywood, and MDF.

Predrill

To predrill means to drill a hole in wood before driving a screw or nail. Predrilling helps to prevent cracking the wood.

Rail

A rail or rails are the horizontal parts of a door or frame.

Related: How to Build DIY Shaker Cabinet Doors

Rip Cut

A rip cut is made with the grain of the wood or along the length of the board.

Router

A router is a handheld power tool used to cut decorative edges on workpieces and to rout grooves or dados in workpieces.

Router Table

A router table allows a handheld router to be mounted in a table.

Related: How to Use a Router Table

Sand

To smooth a piece of wood with sandpaper either by hand or with a power sander.

Related: 11 Secrets for Sanding Wood Projects Like a Pro

Stile

A stile or stiles are the vertical parts of a door or frame.

Related: How to Make DIY Custom Size Frames

Table Saw

A table saw is essentially a circular saw flipped upside down and mounted to the underside of a table.

Related: How to Buy the Best Table Saw for the Money and Beginner’s Guide to Table Saw Safety

Tape Measure

A tape measure or measuring tape is used for making measurements.

Workpiece

A workpiece is a piece of wood that is being worked with a tool like a pocket hole jig.

Final Thoughts

There are many terms unique to woodworking that can be intimidating to beginners. Use this tutorial as the glossary for all of those DIY projects and get the free printable for your workshop!

Thank you for stopping by. If you found this information helpful, would you please pin it to Pinterest? Other DIYers would appreciate it and I would too! Thank you – Scott

Thank you so much for this very helpful article.