How to Assemble an Ortur Laser Master 2

Learn how to assemble an Ortur Laser Master 2. We’ll look at what a laser engraver does, what you need to get started with laser engraving, and helpful assembly tricks.

Ortur Laser Master 2 Assembly Tips and Tricks

The Ortur Laser Master 2 is a laser engraver that can be used to engrave metal, glass, and wood. In this tutorial, we’ll look at how it can be used for woodworking and what you need to get started with laser engraving. Plus, I’m sharing a step-by-step assembly tutorial, and helpful assembly tips and tricks.

This tutorial is not sponsored. I bought the Laser Master 2 online and had it shipped to my home.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Before we get into how to assemble an Ortur Laser Master 2, be sure to click the subscribe button at the bottom of this page to sign up for my FREE weekly newsletter loaded with helpful pocket hole tricks, space-saving workshop ideas, clever DIY tips and more!

Table of Contents

What is the Ortur Laser Master 2?

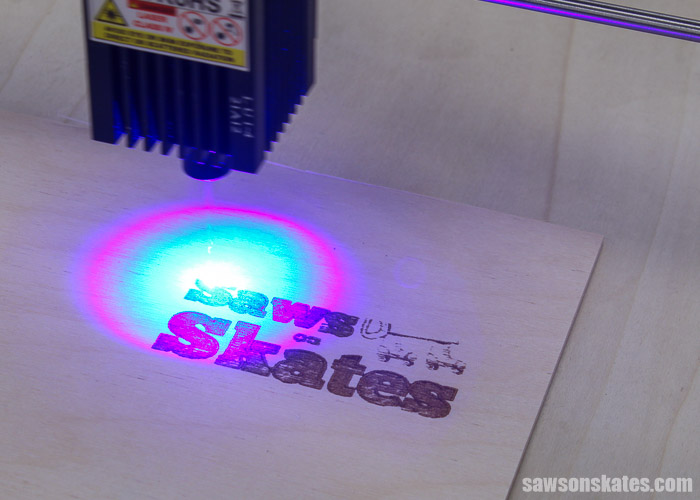

The Ortur Laser Master 2 is a laser engraver. LaserAX defines laser engraving as “a process that vaporizes materials into fumes. The laser beam acts as a chisel, incising marks by removing layers from the surface of the material.”

The Laser Master 2 is available in three variations: 7 watt, 15 watt, and 20 watt. I bought the 20w version for this tutorial.

The 7 watt, 15 watt, and 20 watt all have a large engraving area. It measures 400mm × 430mm or about 15-¾” × 17″.

What Can You Do with the Laser Master 2?

The Laser Master 2 can be used to engrave metal, glass, and wood. It can also be used to cut wood up to 3mm thick. For this tutorial, I’m going to focus on how it can be used for woodworking.

Engrave Wood

The Laser Master 2 can be used to engrave wood projects. That means we could use it to personalize coasters, cutting boards, and more with photos, or text like family names, etc.

Cut Wood

It can also be used to cut wood up to 3mm thick. It’s great for making 3-dimensional projects like Christmas ornaments, jewelry like wooden earrings, boxes, 3D puzzles, dollhouse furniture, and more.

The difference between engraving and cutting is the number of passes the laser will need to make over the material. So far I’ve tested a handful of engraving projects and I’ve been able to get my desired look with just one pass.

It takes multiple passes to cut 3mm plywood. Sometimes six to seven passes. I’m mentioning this because it will take a little extra time to cut wood. For example, I made some wooden refrigerator magnets that measured about 2-¼” in diameter. Between engraving and cutting, it took about 30 minutes to make.

What Kind of Wood Can You Use with the Laser Master 2?

The Laser Master 2 can be used to engrave just about any kind of wood. But keep in mind that all woods will react differently. This means we should test the material first. From there, we can adjust the speed and intensity of the laser.

The Laser Master 2 can be used to cut wood up to 3mm thick. I’ve been working with sheets of this 1.5mm plywood and this 3mm plywood. I’ve read that it’s easier for the laser to cut through solid wood rather than plywood. From what I understand the glues used to bind the plywood sheets are more difficult for the laser to cut through.

Back to Table of ContentsWhat Do You Need to Use the Laser Master 2?

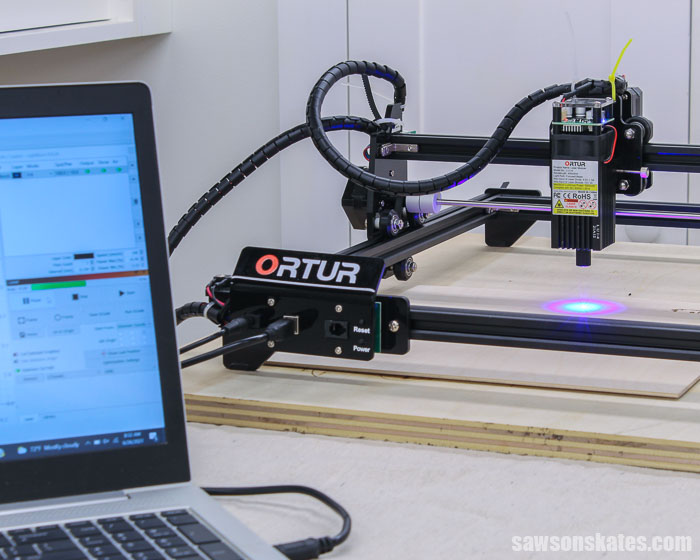

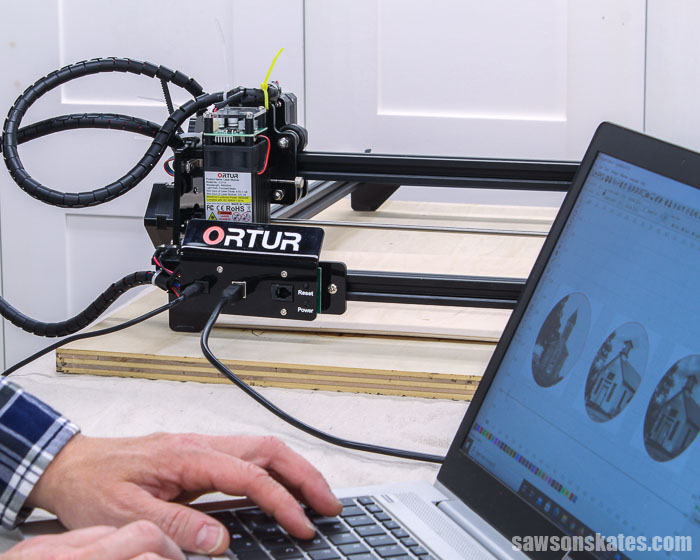

You’ll need a few things to use the Laser Master 2. First, you’ll need a computer. You’ll also need some software that will tell the laser engraver what to do.

The instruction manual for the Laser Master recommends using LightBurn. LightBurn has a free 30 day trial period. After 30 days there is a $40 annual charge. So far I’ve found LightBurn easy to use (with the help of a few YouTube videos!)

You’ll need an area to set up the laser engraver. I would recommend an area with ventilation. The laser causes the wood to smoke as it engraves or cuts. You’ll also want it in an area where you can keep an eye on it (with safety glasses) because the wood can catch on fire.

Speaking of glasses, you must wear safety glasses when using the Laser Master 2. The laser can damage your eyes. A pair of safety glasses are included with the Laser Master, but you may want to upgrade to a better pair.

Step 1. Assemble the Frame

Slide a corner connector in each end of one of the long aluminum frame sections.

💡 TIP #1: Be sure to slide the corner connectors into the groove with the holes.

💡 TIP #2: Be sure the corner connector can slide along the groove. If the connector can’t move past the end, remove it and insert the other end into the groove.

Slide a short frame section onto each corner connector and attach through the predrilled holes with 2 long screws.

💡 TIP: The connectors might need to be adjusted later, so don’t fully tighten the screws.

Use the Allen wrench to tighten the set screws in the corner connectors. Again, don’t fully tighten the set screws.

Slide 2 nuts into the outside groove of each of the short frame sections.

Slide a corner connector in each end of the second long aluminum frame section. Then attach through the predrilled holes with the remaining 2 long screws. Again, don’t fully tighten the screws.

❕ IMPORTANT: It’s a good idea to make sure the frame is square.

I measured from corner to corner. If the measurements are the same, the frame is square.

My measurements were not the same, so I loosened the screws and adjusted the frame until the measurements were the same.

Then, I tightened the four screws and eight set screws.

Step 2. Install the X-Axis Assembly

Slide the X-axis assembly on the short sides of the frame. The single roller goes on the bottom and the two rollers go on the top.

Step 3. Attach the Feet

The manual said to “take out 2 timing belts” but it didn’t say what to do with them. So I placed them in the grooves with the ridges facing down.

Next, I installed the rear feet. The flat side of the X-axis assembly is the back of the engraver.

Push the timing belt through the flat hole in the foot.

Attach it to the hole drilled into the frame with a washer and small screw. Attach the other side of the foot with a screw into the nut in the groove. Repeat for the other rear foot.

Then, working from the feet that were just installed, slide the belt under the first roller, over the timing pulley, and under the second roller.

💡 TIP: I used the tip of a pencil to help work the belt around the rollers and pulley.

I held a piece of paper behind the belt so that you can see how it goes over the timing pulley.

Next, I installed the front foot. When you’re looking at the front of the engraver, the foot is on the right side. Remember, the flat side of the X-axis assembly is the back of the engraver.

Push the timing belt through the flat hole in the foot. Attach it to the hole drilled in the frame with a washer and small screw. Attach the other side of the foot with a screw into the nut in the groove.

Next, slide a nut into the top groove of the left side (the side without a foot).

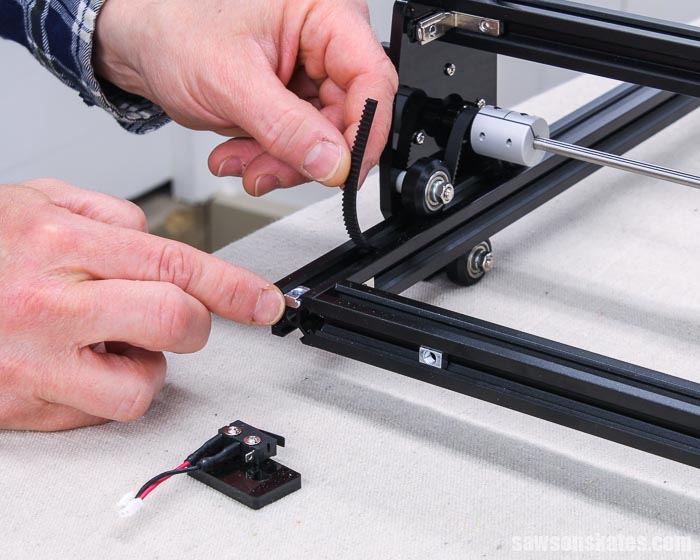

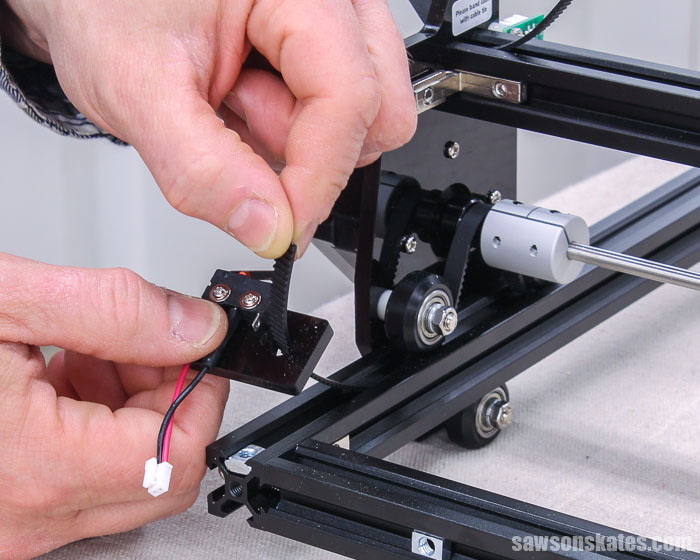

Push the timing belt through the flat hole in the Y-limit switch.

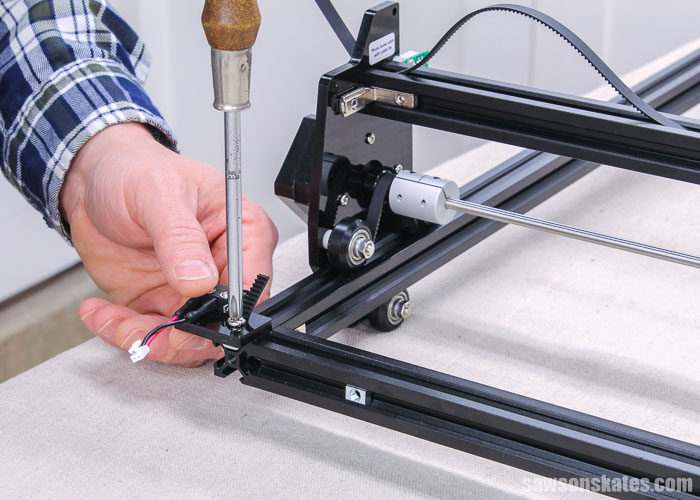

Attach it to the nut in the frame with a washer and small screw. Just snug the screw, the switch can be positioned properly later.

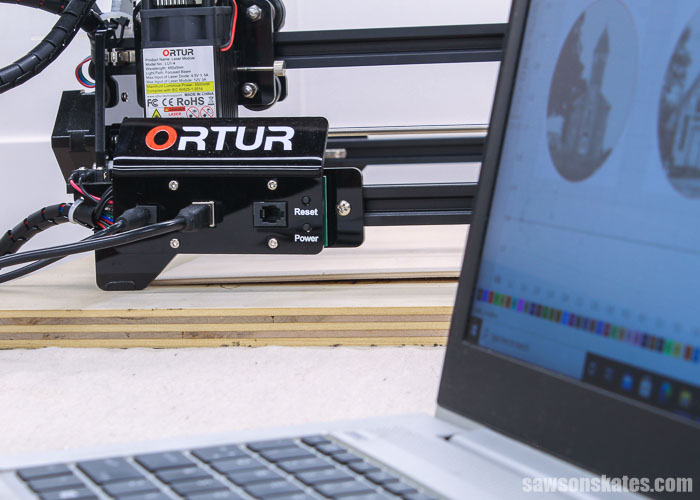

Then, attach the mainboard assembly with two short screws through the holes drilled in the frame and the nut in the groove.

Next, I tested the movement of the X-axis assembly. It felt like there was some slack in the belt, so I loosened the screw and adjusted the tension of the belt.

Step 4. Install X-Axis Motor

Gently pull up on the X-axis belt, position the motor from the back of the engraver with the gear under the belt.

💡 TIP: Be sure the wire connector on the motor is facing up.

Attach the motor with four screws.

Step 5. Attach the Laser

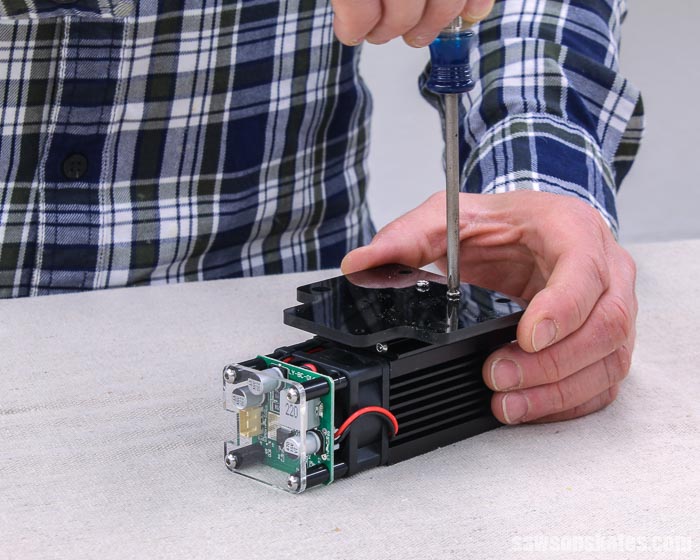

Remove the paper from the backboard.

💡 TIP: I had trouble lifting the paper, so I used an X-Acto knife to lift the corner of the paper.

Attach the laser to the backboard using 2 screws.

Attach the laser assembly using 4 cap nuts.

💡 TIP: Be sure the laser is pointing down.

Step 6. Connect the Wires

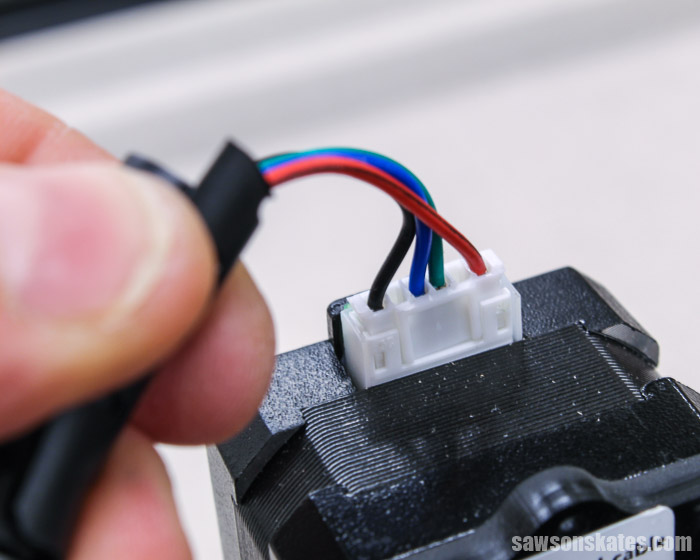

The three pin plug connects to the laser.

The six pin plug connects to the X-axis motor.

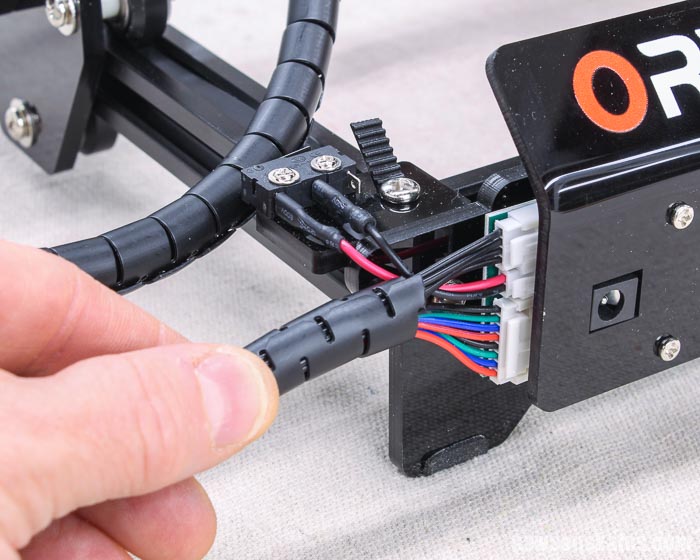

On the side of the X-axis assembly, the three pin plug connects at the top, the four pin plug connects at the bottom, and the six pin plug connects to the Y-motor.

At the mainboard, the 4 pin plug connects at the top, the two pin plug connects at the bottom, and the eight pin plug connects at the bottom.

After the wires were connected, I used the enclosed zip ties to connect the wires to the engraver. I noticed sometimes the wires would get caught while the engraver was in use. So I removed some of the original zip ties, repositioned the wires, and reattached them with some zip ties that I had on hand.

The Laster Master 2 is now ready to use.

Back to Table of ContentsMy Review of the Laser Master 2

This is my first experience with a laser engraver and overall I’m pleased with my purchase. Compared to the other laser engravers that I researched, the Laser Master 2 was relatively affordable.

The assembly instructions in the instruction manual were a little vague, but the assembly process was quick and easy. All of the pieces fit together properly.

Without any prior experience, I was able to get it up and running quickly.

I wouldn’t call them cons, but there are a few things that I was not expecting.

First, it took longer than I expected to engrave or cut, but the results are worth the wait.

The second was the number of passes it takes to cut through the material. It can take six to seven passes to cut. My understanding is higher-powered lasers can cut in fewer passes, but those lasers are much more expensive.

As with anything new, mastering the Laser Master will take some practice. You should expect that your first few projects might not turn out as well as you hoped.

But with lots of practice, I’ve gotten the Laser Master to do a decent job of cutting 3mm plywood. After lots of research, I’ve learned that I’ll need some additional equipment to make it do a better job of cutting. It will need “air assist”.

Air assist blows any debris out of the cut line so the laser can reach where you want it to cut. It will also blow the smoke away. The smoke can reduce the effectiveness of the laser.

A nozzle is connected to the laser. The nozzles can be 3D printed or you can buy one from Etsy. Then the nozzle is connected with a hose to an aquarium pump. Air assist will be my first upgrade for the Laser Master 2.

Back to Table of ContentsWhere to Buy the Ortur Laser Master 2

I bought my Laser Master 2 here and had it shipped to my home.

Back to Table of ContentsFinal Thoughts

The Ortur Laser Master 2 is a laser engraver that can be used to engrave and cut woodworking projects. It’s easy to assemble, easy to use, and relatively affordable.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

I just wondered now after having used this engraver, would you consider purchasing a larger size? I know I purchased a smaller CNC machine and within a month, I was wishing I had waited and bough a larger machine. We appreciate your weekly information and enjoy reading about new DIY projects.

Thanks, Frank

Hi Frank – Thank you for the compliments. So far I’m pleased with my purchase… it does just about everything that I want to do. Larger engravers can cost several thousand dollars. The Laser Master 2 was a fraction of that. For me, it was a good way to get into laser engraving. And an inexpensive way to make sure it was something that I enjoyed doing. That said, down the road, I may consider purchasing a larger engraver.

How much did the Kit & accessories cost to get it to a turn-key system?

Does it come with design software and is it user friendly?

Hi Terry – I bought the Laser Master 2 here. As I mentioned in the What Do You Need to Use the Laser Master 2 section of this tutorial it does not come with design software. I also mentioned: “The instruction manual for the Laser Master recommends using LightBurn. LightBurn has a free 30 day trial period. After 30 days there is a $40 annual charge. So far I’ve found LightBurn easy to use (with the help of a few YouTube videos!)”

The only items I purchased for this tutorial were the Laser Master 2 and the LightBurn software.

Despite what the website says, the Ortur LM2, and pretty much any diode laser, is not really meant to cut wood. Especially not the “20w” since you’re not actually getting 20w output, it’s more like 4.5w. It also cannot engrave metal, unless it is anodized aluminum, and in that case, it’s just removing the top coat off and not really “engraving” it. You’ll burn out the laser fast if you try to cut wood with it, just fyi. I have 3 of these machines and they are good for engraving, but you gotta be really focused to get good results.

I bought the same exact system and software. I agree 100% with your finding and tutorial.

I to thought this was a great starting point for my investment in time and expense.

Good burning to all.