Kreg Straight Edge Guide: How to Use and Review

The Kreg Straight Edge Guide helps circular saws, jigsaws, and trim routers make straight, accurate cuts. Learn how to set it up and if I would use it again.

Kreg Straight Edge Guide

Circular saws, jigsaws, and routers are versatile tools, but they don’t usually cut straight without a little help from a fence or a guide. The Kreg Straight Edge Guide turns a circular saw and a jigsaw into a tool that makes accurate rip cuts. And it turns a trim router into a tool that makes accurate grooves and dados.

In this tutorial, I’ll show you step-by-step how to set it up and use it. Plus, in my review, I’ll let you know if I will ever use it again.

Thank you to my friends at Kreg Tool for sending me the Straight Edge Guide. I received this tool in exchange for my honest review. All thoughts and opinions are my own.

You may also enjoy How to Use a Kreg Crosscut Station (+ My Review).

Table of Contents

- What is the Kreg Straight Edge Guide?

- What is Included?

- What Tools Can You Use with the Kreg Straight Edge Guide?

- What Can You Cut with the Kreg Straight Edge Guide?

- Can You Cut Angles?

- Can You Cut Bevels?

- What Blade Should I Use?

- How to Assemble the Kreg Straight Edge Guide

- How to Calibrate the Kreg Straight Edge Guide

- How to Use the Kreg Straight Edge Guide

- My Review of the Kreg Straight Edge Guide

- Where to Buy the Straight Edge Guide

What is the Kreg Straight Edge Guide?

Kreg Tool has recently added several new cutting solutions to their family of tools. Previously they released the Kreg Rip-Cut which attaches to a circular saw to make straight, accurate rip cuts. And the Kreg Accu-Cut that turns a circular saw into a track saw.

Related: 4 Ways to Make Straight Cuts With a Circular Saw

Their latest cutting solutions include the Crosscut Station which turns a circular saw into an accurate way to make crosscuts and miter cuts. Think of it as a miter box for your circular saw.

Related: Kreg Crosscut Station Review (It’s Not for Everyone)

The Kreg Straight Edge Guide rounds out the family of cutting tools by turning a circular saw into another accurate way to make long rip cuts. And unlike their other cutting solutions, it can also be used with a jigsaw and a trim router.

One difference between the Rip-Cut and the Accu-Cut is the Straight Edge Guide clamps to the workpiece.

The Straight Edge Guide is available in two lengths, the Straight Edge Guide has a 4-foot cutting capacity and the XL has an 8-foot cutting capacity. An expansion pack is available if you want to make the cutting capacity even longer.

Back to Table of ContentsWhat is Included?

The Straight Edge Guide includes:

- (2) 28” Guide Rails

- (2) Paired Connector Bars

- (2) Cutline Indicator Arms

- Adjustable GripMaxx™ Clamp

- Handle

- Owner’s Manual

The Straight Edge Guide XL includes all of the items above plus two 24” Guide Rails and it increases the number of Paired Connector Bars from two to six.

You will need to provide your own circular saw, jigsaw, or trim router. You will also need a piece of rigid foam board insulation.

The foam board makes a great work surface for cutting large sheets of plywood and MDF. And more importantly, it prevents the saw blade from cutting your workbench, or pavement/concrete when working on the ground.

What Tools Can You Use with the Kreg Straight Edge Guide?

The Straight Edge Guide works with circular saws, jigsaws, and most trim routers with the baseplate attached.

Circular Saw

- Works with circular saws with a 5-½” blade or larger

- The baseplate needs to have 1” to 5-½” between the blade and the edge of the baseplate

- The low profile of the Straight Edge Guide (⅜”) shouldn’t interfere with most circular saw motors

- Works with saws with the blade on the left or right side

📝 NOTE: I’m using my DeWalt circular saw for this tutorial.

Jigsaw

- The baseplate needs to have 1” to 5-½” between the blade and the edge of the baseplate

- Requires a slightly different setup when calibrating

Trim Router

- The baseplate needs to be installed on the router

- The baseplate needs to have 1” to 5-½” between the blade and the edge of the baseplate

What Can I Cut with the Kreg Straight Edge Guide?

The Straight Edge Guide is designed to make straight rip cuts on ¾” thick sheet material like plywood and MDF. It can also be used to cut ¼” and ½” material if it’s properly supported.

It can be used to make bevel cuts with circular saws and jigsaws and dados with a trim router.

Can You Cut Angles?

No, the Straight Edge Guide can’t be used to make angle cuts. It’s designed to make straight, rip cuts.

Back to Table of ContentsCan You Cut Bevels?

Yes, the Straight Edge Guide can be used with the blade tilted to make bevel cuts.

Back to Table of ContentsWhat Blade Should I Use?

We’ll want to choose a blade for making rip cuts in the material that we’re cutting (plywood, MDF, etc.)

Related: How to Change a Circular Saw Blade

💡 TIP: Be sure to choose a blade that matches the blade size and arbor size of your saw. These sizes are usually printed on the saw. For example, my circular saw requires a 7-¼” blade with a ⅝” arbor.

How to Assemble the Kreg Straight Edge Guide

📝 NOTE: I have the XL version, but my workshop is small, so I only used the two 28” guide rails for this tutorial.

Step 1. Assemble the Connector Bars

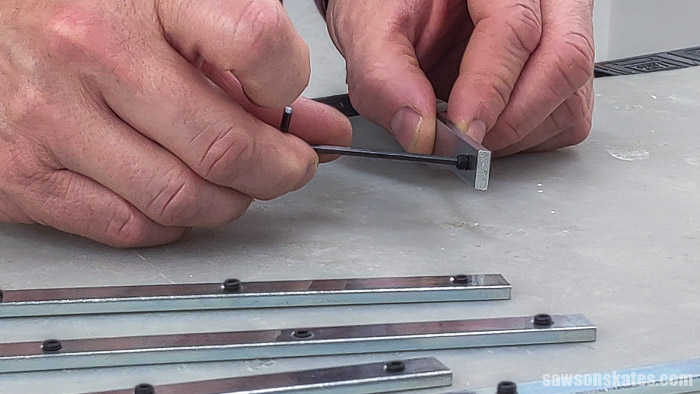

Thread the set screws into the connector bars.

💡 TIP: The set screws are small and tricky to thread into the holes by hand. Instead, I found it was easier to place the set screw on the Allen wrench and then thread it into the hole.

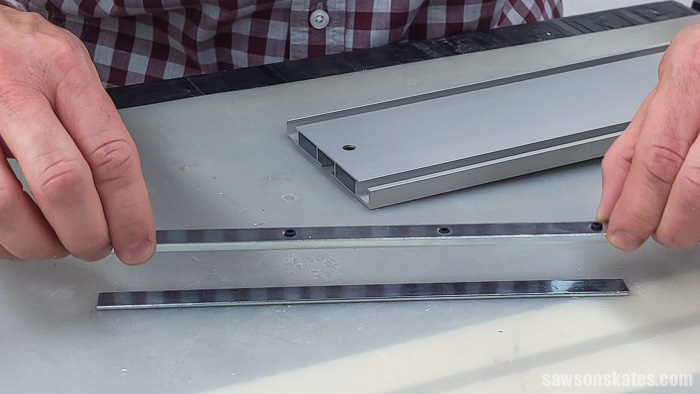

Place an upper connector bar on top of a lower connector bar.

Slide both connector bars about halfway into the groove in the guide rail with the clamp. Repeat for the other side.

Then, partially snug the set screws. The connector bars might need to be adjusted so don’t fully tighten the screws.

Step 2. Attach the Guide Rails

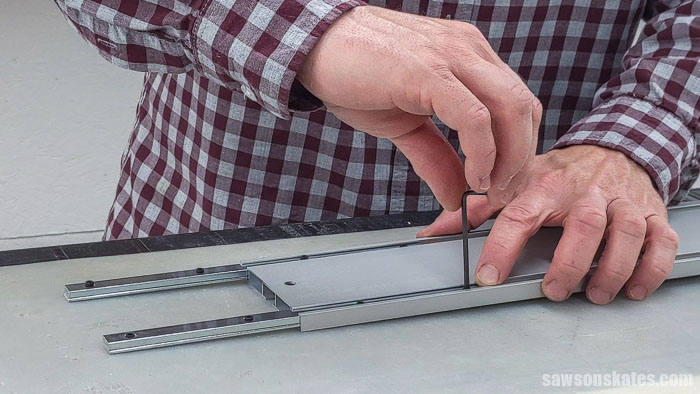

Slide a guide rail section onto the connector bars.

📝 NOTE: I had to loosen the set screws so that I could slide the next guide rail over the connector bars.

💡 TIP: Be sure the hole in the guide rail is facing outward.

Use a straightedge to align the two guide rail sections. I used a 24″ level. Then use the Allen wrench to fully tighten the set screws.

Repeat this step to attach the remaining sections for the XL or expansion pack.

Step 3. Install the Clamp

Slide the adjustable clamp into the groove on the bottom of the guide rail.

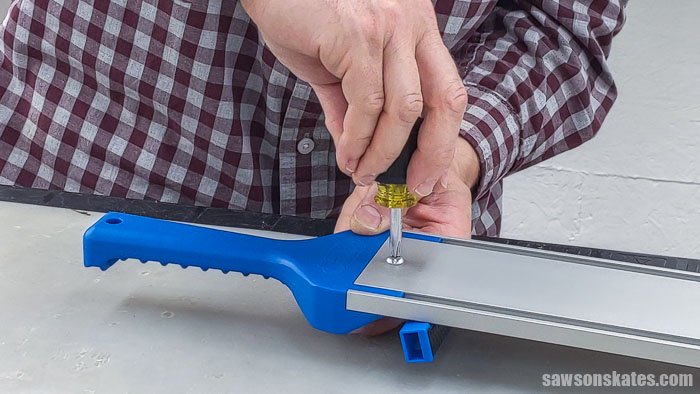

Step 4. Attach the Handle

Slide the handle into the grooves in the guide rail. Then, attach the handle with a screw and nut.

There’s a place to store the Allen wrench on the underside of the handle.

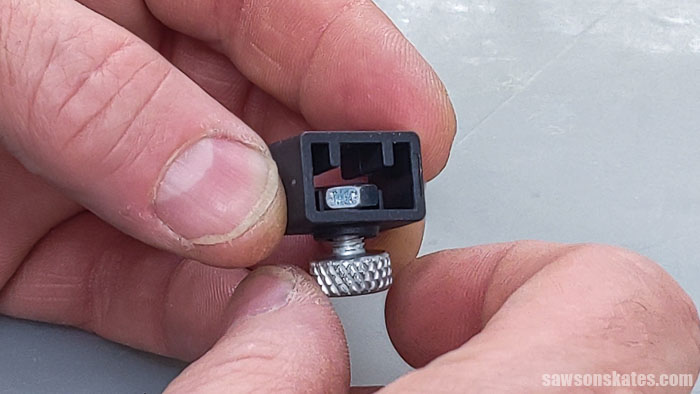

Step 5. Assemble the Cutline Indicator Stops

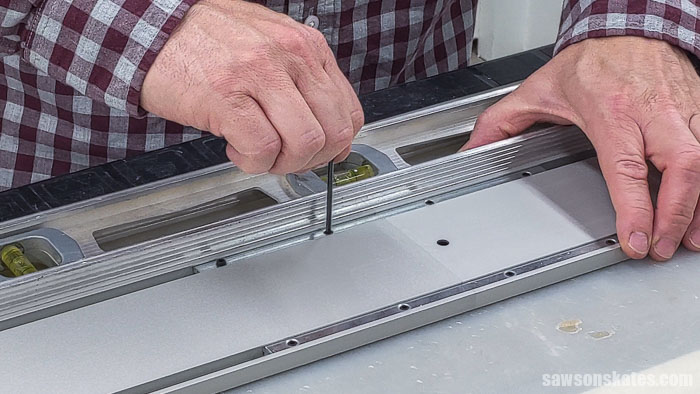

Slide a nut into the cutline indicator stop. Then, attach a thumbscrew.

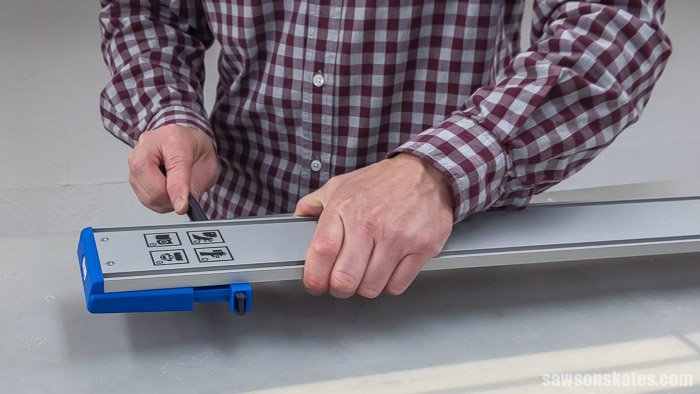

Step 6. Install the Indicator Arms

📝 NOTE: The wider side of the indicator arm should face inward when installed in the clamp.

Slide the indicator arm into the slot in the guide rail. Then, slide a cutline indicator on the other end of the indicator arm.

How to Calibrate the Kreg Straight Edge Guide

Step 1. Make the Reference Marks

❕ IMPORTANT: Unplug or remove the battery from the saw.

Position the circular saw on a piece of ¾” plywood and set the blade so that it will cut an ⅛” deeper than the plywood.

Next, I placed a piece of rigid foam insulation on my workbench. The foam will protect the workbench when making cuts.

Lift the blade guard and position the saw at the back of the plywood with the blade against the plywood.

💡 TIP: Don’t push too hard on the saw. Otherwise it could cause the blade to flex and make the location of the marks inaccurate.

Use a pencil to mark the edge of the baseplate on the back edge of the plywood.

Then, move the saw and mark the baseplate on the front edge of the plywood.

Step 2. Position the Guide Rail

Place the guide rail on the plywood and position it on both reference marks.

📝 NOTE: The guide rail will only be positioned on the marks when it’s being calibrated. After it’s calibrated the indicator arms will be positioned on the marks.

Slide the clamp against the plywood. Then, use one hand to hold the clamp against the plywood and use the other hand to pull the handle to tighten the clamp.

Loosen the stop and position the cutline indicator arm against the end of the plywood.

Then, push the stop against the clamp and tighten the thumbscrew.

Repeat this step for the other cutline indicator arm. The Straight Edge Guide is now calibrated and ready to make some cuts.

Back to Table of ContentsHow to Use the Straight Edge Guide

Step 1. Mark the Workpiece

Measure and make mark on one edge of the workpiece.

Measure and make mark on the other edge of the workpiece.

Mark an “X” on the waste side. The waste side is the side you don’t want.

Step 2. Position the Cutline Indicators

Position the guide rail on the side of the workpiece that you want to keep with the cutline indicator arms facing towards the waste side. Then, slide the clamp towards the workpiece.

Slide both of the cutline indicator arms so the face is aligned with the marks.

Use one hand to hold the clamp against the workpiece and use the other hand to pull the handle to tighten the clamp.

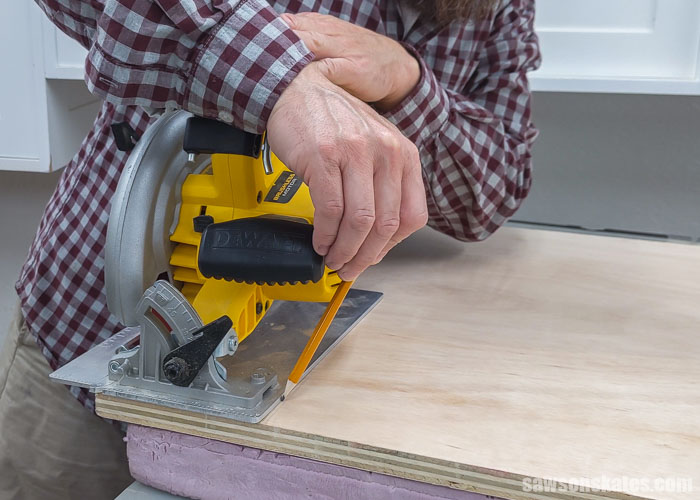

Step 3. Make the Cut

Slide the cutline indicator arms back towards the clamp.

💡 TIP: Be sure to set the blade so that it will cut an ⅛” deeper than the workpiece.

Position the saw on the guide rail. Make sure the blade is not touching the workpiece. Turn the saw on and let it come up to full speed.

Then make the cut. Be sure to keep the baseplate against the guide rail for the entire length of the cut.

To remove the guide, just pull up on the handle.

Back to Table of ContentsMy Review of the Kreg Straight Edge Guide

The Kreg Straight Edge Guide is reasonably priced, easy to assemble, and easy to set up. Overall it’s a great way for beginners to make accurate rip cuts.

For me, there are a few drawbacks to the Straight Edge Guide. In my small workshop it would be tricky to store when fully assembled. Especially the 8-foot XL version. I would probably need to assemble and disassemble each time that I needed to use it.

Related: My 12×13 Small Woodshop Layout

I’m not careful with things, and I feel like I might bend or break the indicator arms. It would be a great feature if the indicator arms could be easily separated or rotated under the guide for storage.

Would I Use it Again?

So the big question is: would I use it again? I should preface this by saying that I don’t usually use plywood for my builds. So I don’t often need a tool like the Straight Edge Guide. But yes, I would use it again. That said, depending on the type of cut that I needed to make, there are a few tools that I might reach for first before using my Straight Edge Guide.

The reason is, with the Straight Edge Guide, you have to measure twice then position the guide in place. The accuracy of the cut depends on your ability to line up the cutline indicators with your marks.

And you have to remember to move the cutline indicators out of the way before making your cut. I have a feeling that I would forget to do this and run my saw into them!

The tools I might reach for before using the Straight Edge Guide are my table saw, Kreg Rip-Cut, or a DIY crosscut jig.

Table Saw

With a table saw you can measure once, set the fence once, and make accurate, repeatable cuts. The drawback is that it can be unsafe to cut large sheets on a table saw. Also, I understand that some beginners are uncomfortable with using a table saw.

Kreg Rip-Cut

My second choice would be a Kreg Rip-Cut. It works in a similar way to the table saw. First, you attach your circular saw to the Rip-Cut. Then, measure once and set the fence once. The fence follows the edge of the workpiece and allows you to make accurate, repeatable cuts.

The drawback to the Rip-Cut is that it has a maximum cutting capacity of 24”.

The Kreg Rip-Cut is my go-to tool for ripping plywood sheets that are too large to safely cut on my table saw.

DIY Crosscut Jig

A DIY crosscut jig works similar to the Straight Edge Guide. You have to measure twice then position the jig in place. The accuracy of the cut depends on your ability to line up the edge of the jig on your marks.

But for me, I think it’s easier to place the edge of the DIY crosscut jig on top of my marks than it is to line up the cutline indicators of the Straight Edge Guide next to my marks.

Also, the DIY crosscut jig doesn’t have cutline indicators sticking out which makes it easier to store the guide.

Related: How to Make a DIY Circular Saw Crosscut Jig

Back to Table of ContentsWhere to Buy the Straight Edge Guide

You can buy the Straight Edge Guide here and have it shipped to your home.

Back to Table of ContentsFinal Thoughts

Circular saws, jigsaws, and routers are versatile tools, but they don’t usually cut straight without a little help from a fence or a guide. The Kreg Straight Edge Guide turns a circular saw and a jigsaw into a tool that makes accurate rip cuts. And it turns a trim router into a tool that makes accurate grooves and dados.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!