Drilling Pocket Holes on Miter Joints Requires Careful Planning

Drilling pocket holes on miter joints takes a little extra planning but is just as easy drilling pocket holes on butt joints and edge joints

You may also enjoy these 9 Solutions to Common Pocket Hole Problems.

Drilling pocket holes on miter joints takes a little extra thought and planning but is just as easy as drilling pocket holes on butt joints and edge joints. Mitered corners can add a decorative element to picture frames, door frames, and DIY furniture projects. Today we’ll explore three options for drilling pocket holes on mitered corners.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Butt and Edge Joints

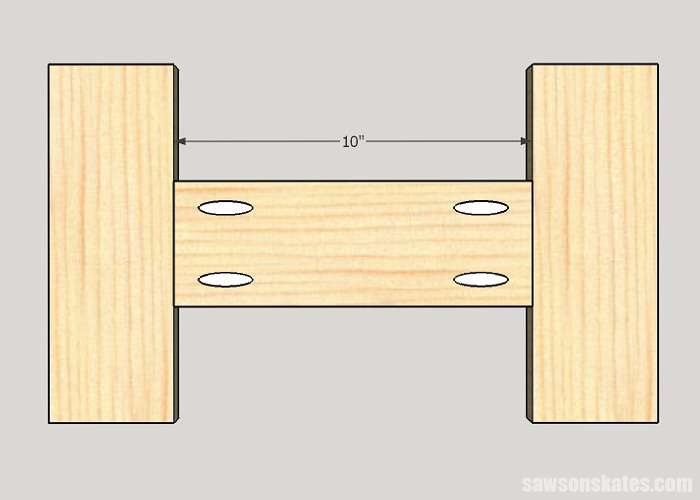

The most common joints made with the Kreg Jig is a butt joint or edge joint. A butt joint joins the end of one piece of wood to the edge of another piece of wood. Common uses for butt joints are frames for side assemblies and door frames.

An edge joint joins the edges of boards. Edge joints are commonly used to create panels and table tops for furniture pieces.

Miter Joints

A slightly more complex joint is a miter joint. Mitered corners can add a decorative element to picture frames, door frames, and DIY furniture projects.

Drilling pocket holes on miter joints takes a little extra thought and planning but is just as easy as drilling pocket holes on butt joints and edge joints once you get the hang of it.

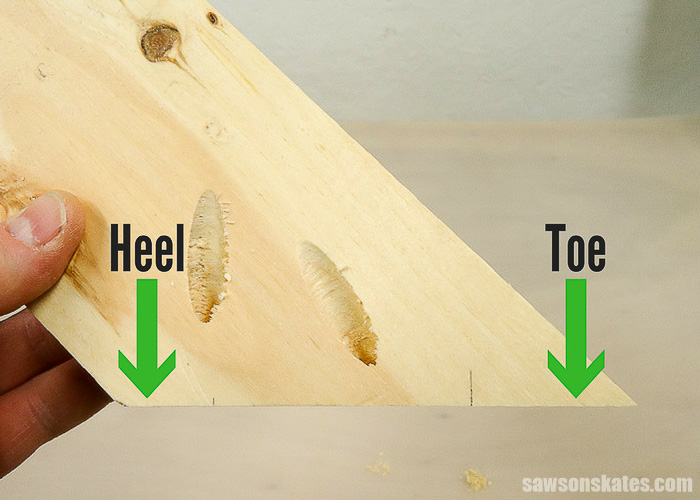

Miter Joint Anatomy

Before we begin let’s look at the “anatomy” of a miter joint. The long point is called the toe. The short point is called the heel.

Kreg Jig Setup

If you are unfamiliar with using the Kreg Jig to make pocket holes I would encourage you to check out my How to Setup a Kreg Jig before drilling pocket holes in miter joints. The guide will show you step by step how to properly setup your jig and use it to build DIY furniture projects.

Do you have a Kreg Jig Mini? Then please skate over to the Kreg Jig Mini Makes Hard-to-Reach Repairs Easy post and grab your FREE 9 page Ultimate Kreg Jig Mini Setup Guide while you’re there!

Test First

No matter if you’re cutting parts for a furniture project or drilling pocket holes it’s always worth your time to make some test pieces. I dedicated an entire post to the importance of creating test pieces. Check out this post to avoid a DIY furniture fail and to learn of the benefits of creating test pieces.

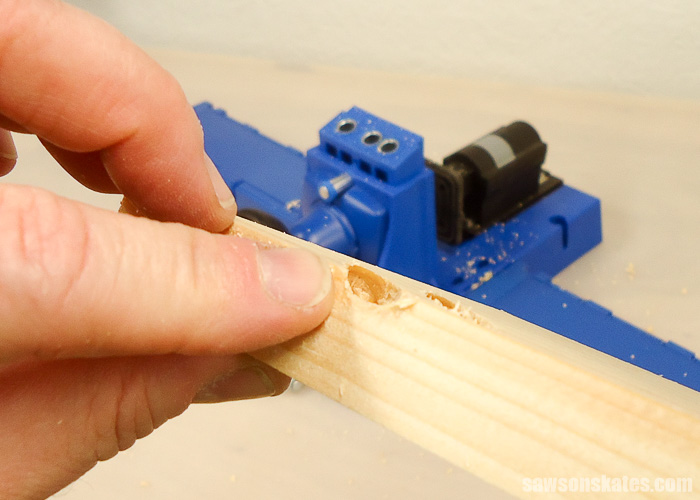

Creating test pieces is especially important when working with pocket holes on miter joints. Get ready because I’m going to give you my best tip for drilling pocket holes on miter joints right now… always look at the back of the jig before drilling pocket holes on miter joints. The reason? It’s very easy to accidentally drill a pocket hole through the edge of your board.

Take a look at this setup. The hole is exposed. If we were to drill a pocket hole in this board right now we would drill through the edge or side of the board.

And here’s the pocket hole drilled through the edge of the board. This is NOT an attractive look for our DIY furniture. DON’T DO THIS!

Here’s what you want the back of the of the jig to look like. You always want the hole covered. This will ensure the pocket hole will be drilled through the face of the board rather than the edge of the board

Drilling Pocket Holes on Miter Joints

Option 1

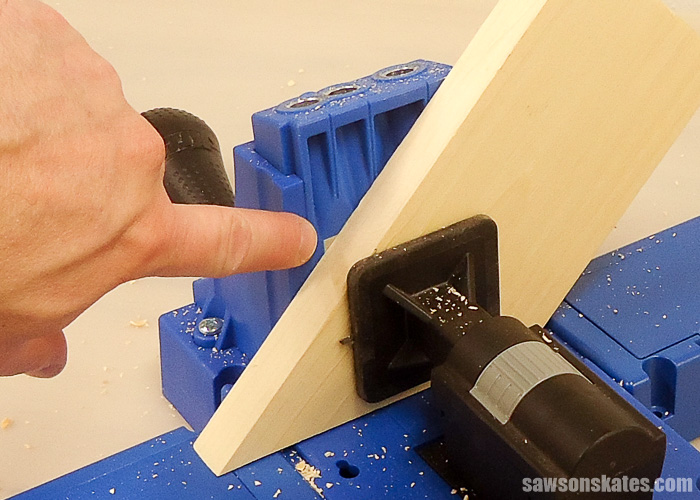

First, cut your miter joint. Then place your board in your Kreg Jig. Boards like a 1×4 can be placed in the jig and drilled with the “A” and “C” guides. Boards like a 1×3 can be placed in the jig and drilled with the “B” and “C” guides.

As I mentioned above, be sure to check the back of the jig before drilling the pocket holes. The hole in the drill guide must be covered by the wood or you will drill through the edge of your board.

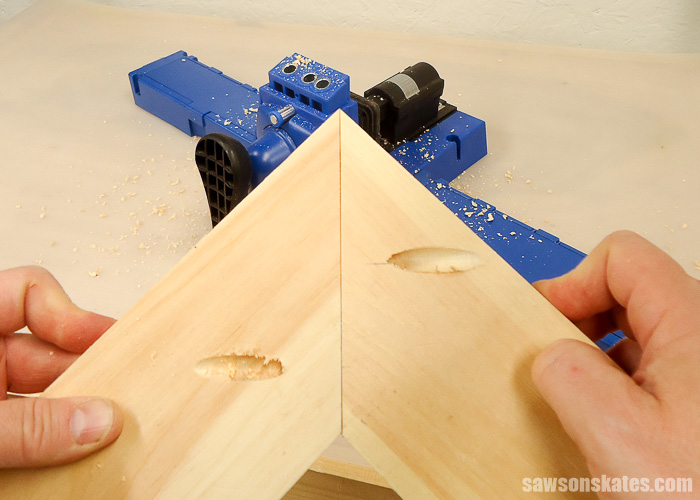

Here’s a look at a completed joint on a 1×3.

Option 2

Option 2 is similar to option 1, but rather than drilling pocket holes on one side of the miter joint, pocket holes are drilled on both sides of the miter joint.

First, cut your miter joint. Place the joint together. Mark one side near the toe and one side near the heel. Place your board in the Kreg Jig. Be sure to check the back of the jig before drilling the pocket holes. The hole in the drill guide must be covered by the wood or you will drill through the edge of your board. Drill the pocket hole and then repeat for the other side.

Option 3

If you look at option 1 and option 2 you’ll notice the pocket holes are far away from the toe. This means the toe could spread or open with seasonal changes.

Option 3 positions the pocket screw a little closer to the toe. First, put the board in the jig as you normally would and drill a pocket hole in the heel. Remove the board from the jig. Remove the drill guide from the jig. For 3/4″ thick stock attach a spacer block to the drill guide.

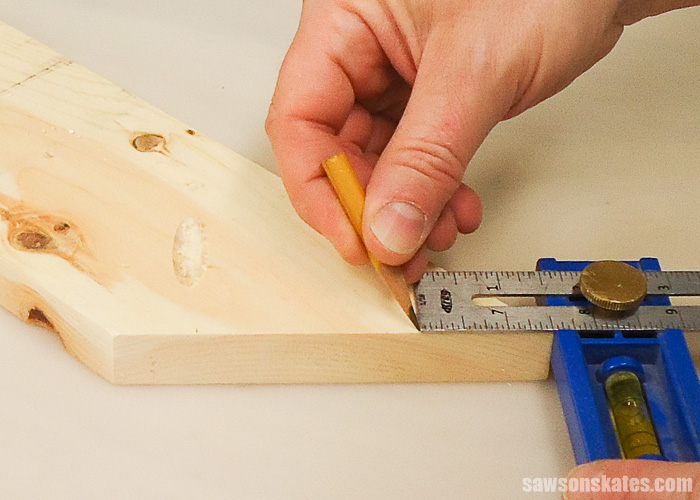

Use a Kreg Multi-Mark to measure in from the toe 1-1/2″. Make a mark at this location.

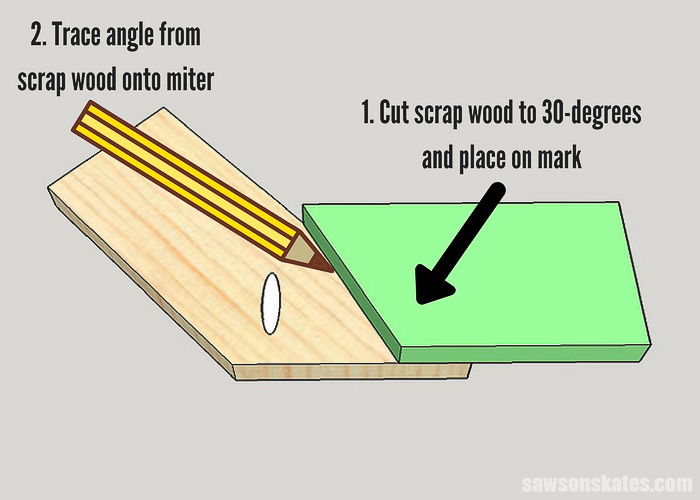

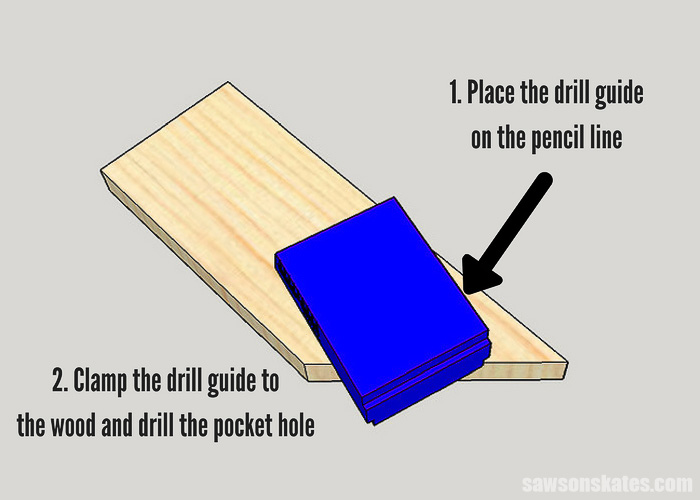

The drill guide needs to be angled away from the toe by 30-degrees. To help with this I cut a piece of scrap wood to 30-degrees. I placed the scrap wood on the pencil mark and traced the angle onto the miter.

Then place the drill guide on the pencil line, clamp the drill guide to the wood using an Automaxx Face Clamp and drill the pocket hole.

The pocket holes will look like this.

Here’s a look at the completed joint.

Drilling Pocket Holes on Miter Joints Cheat Sheet

Want a handy-dandy Drilling Pocket Holes on Miter Joints Cheat Sheet to keep in your workshop? Just click below and download your FREE cheat sheet NOW!

Attaching the Miter Joints

5 Tips for attaching pocket holes on miter joints:

- Use pocket screws

- Use wood glue

- Use clamps

- Set the clutch on your drill

- Use candle wax to prevent the wood from cracking

Use Pocket Screws

Pocket screws are specifically designed to work with pocket holes. Pocket screws have threads only on the lower portion, while the upper portion or shank is not threaded. This design allows the shank of the pocket screw to slide through the pocket hole and pull the joint tight.

Unlike pocket screws, regular wood screws have threads along the entire length. A regular screw won’t slide through a pocket hole. The threads may not only crack the board with the pocket hole, but it might not pull the other board tight, yielding in an ill-fitting joint. Use only Kreg brand pocket screws or another authentic pocket screw by another brand.

Use Wood Glue

Pocket hole screws do a great job of making a secure joint so pocket hole joints don’t require wood glue, but that doesn’t mean you shouldn’t use glue when assembling your furniture projects.

When a pocket screw is screwed through an angled pocket hole it draws the two pieces of wood together tightly. The pocket holes make a strong joint, but that doesn’t take into account the seasonal movement of wood.

You can’t stop the seasonal movement of wood, but you can help reduce some of these issues by applying glue to the joints.

Use Clamps

Don’t try to properly align the joints with your hands. You’ll end up with glue all over your hands (you did use glue, right?) and you’ll likely end up with misaligned joints.

Nothing beats the mechanical advantage of a clamp. Did you know there’s a science to clamping? There is and you can learn more about it in my 6 Tips to Clamp Your DIY Project Like a Pro. Clamping will ensure your joints will be stronger and your furniture projects will look more professional.

My Kreg K5 Master System came with an Automaxx Face Clamp which I used to clamp my test pieces for this drilling pocket holes on miter joints demonstration. If I were actually building a picture frame, door frame or furniture project I would use a set of right angle clamps like these. This way you can layout the entire piece, get all of the joints the way you want them, tighten the clamps and attach with pocket screws.

The limitation of the right angle clamps is they typically only allow for boards up to 3″ wide. For wider boards, you can use a band clamp. Just like using right angle clamps the band clamp allows you to layout the entire piece, get all of the joints the way you want them, tighten the clamp and attach with pocket screws.

Avoid Over Tightening

Pocket holes can easily be stripped, so it’s important to set the clutch on your drill to a low setting – my DEWALT drill works well on 3. When the drill meets a certain amount of resistance, the clutch prevents the drill from driving the screw any further and prevents stripping the pocket hole.

Use Candle Wax

Applying candle wax to the pocket screw lubricates the screw, which reduces friction and lowers the chances of the wood cracking. I keep a candle in my workshop just for this purpose.

Bonus – Hard-to-Reach Pocket Holes

It will happen to all of us at some point. We’ll chuck the pocket hole driver in our drill, attempt to drive the pocket hole screw into the pocket hole and… CRASH!!! The drill/driver combo is too large to fit in our DIY furniture project.

My secret weapon for hard to reach pocket holes is a right angle attachment! Check out why you should add this invaluable tool to your arsenal in this post.

Don’t Make These Pocket Hole Mistakes

Master your pocket hole projects with this FREE ten-page Pocket Hole Mistakes You Don’t Want to Make Guide! The guide is overflowing with useful hints and easy tips to help you avoid time-consuming mistakes. Click below, get your FREE guide, and tackle your next pocket hole project with confidence!

Final Thoughts

Drilling pocket holes on miter joints takes a little extra thought and set up but is just as easy as drilling pocket holes on butt joints and edge joints. Mitered corners can add a decorative element to picture frames, door frames, and DIY furniture projects.

Thank you for stopping by to check out to drill pocket holes on miter joints. Don’t forget to download your FREE drilling pocket holes cheat sheet! If you found this information helpful, would you please pin it to Pinterest? I’d really appreciate it! Thank you – Scott

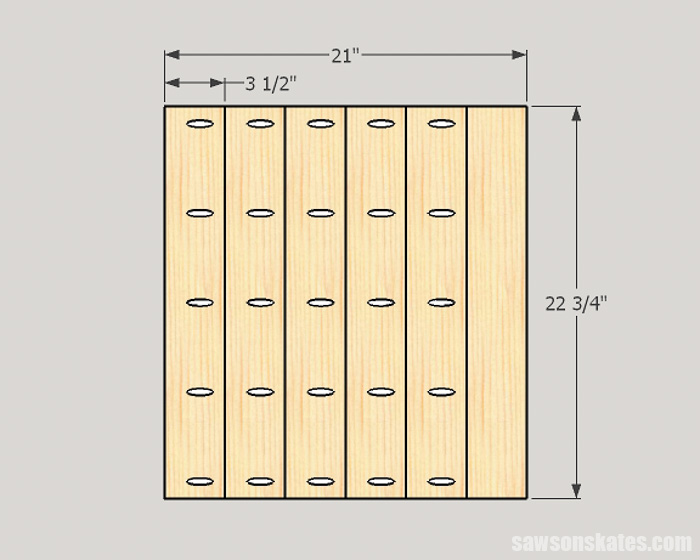

Another excellent and useful post, thank you! My big question is this tho: on edge to edge joining like for making table tops, I always see the pocket holes all in a line. Is there a reason for this? Wouldn’t it be better to have the pocket holes in a staggered or offset configuration? I’m brand new to wood working, so it’s just a thought I’ve been having and would love some input. Thanks!

Thank you, Timber! This is a great question. I have always done pocket holes in a row without even thinking about it! For the official ruling, I reached out to my friends at Kreg Tool. Mike at Kreg said “There really isn’t an inherent benefit or disadvantage to staggering the pocket holes when gluing up a panel. The main reason you see them in line is simply for repetition of measurements from board to board.” So there it is! I hope that helps. I love questions, so please let me know if you have any more.

Thanks for your great tips. Im converting a Sprinter va n to a RV. Ive used the Kreig system before and its working great on plywwood pa nels in thed va

That sounds like a fun project. I love vintage campers, tiny houses and RVs. I’d love to see some pics of your project when you finish. Good luck – Scott

Thank you. This was a great article and very good tip. I appreciate your time and effort in sharing your skills with us. Regards from South Africa

Thank you, Johann. Glad you found the info useful!

Great info! Just ran into a hard to reach pocket hole today! Heading out tomorrow to pick up a right angle attachment. Also, are you not supposed to pre-drill with pocket holes or does it matter? Thanks! Michele