9 Pocket Hole Mistakes You Don’t Want to Make

Setting up the Kreg Pocket Hole Jig and using it to build DIY furniture is sooo easy! Despite that mistakes are easy to make, and trust me, I’ve made most of them! Today I’m sharing with you 9 pocket hole mistakes you don’t want to make.

For your convenience, this post contains affiliate links to supplies or tools I used to complete this project. Purchases made using these links help support the Saws on Skates website and allow me to share more DIY projects. and DIY tips with you. There is no cost to you for using these links. Click here to visit my site policies.

I use my Kreg Jig for nearly every DIY furniture project I build. Over the years I’ve had a lot of pocket hole successes, but I’ve also made a few pocket hole mistakes along the way. Today I’m sharing those mistakes with you, so you don’t make them too!

9 Pocket Hole Mistakes You Don’t Want to Make

We can experience pocket hole problems no matter what brand of pocket hole jig we use. Before we dive into the pocket hole mistakes we want to avoid let’s review what a Kreg Jig does and how to properly set it up for building DIY furniture.

What is Pocket Hole Joinery?

The Kreg Jig uses preset holes to drill angled pocket holes in a piece of wood. A pocket screw, specifically designed for use with pocket holes draws the two pieces of wood together to form a strong joint.

Kreg Jig Setup

Step 1 – Set the Drill Guide

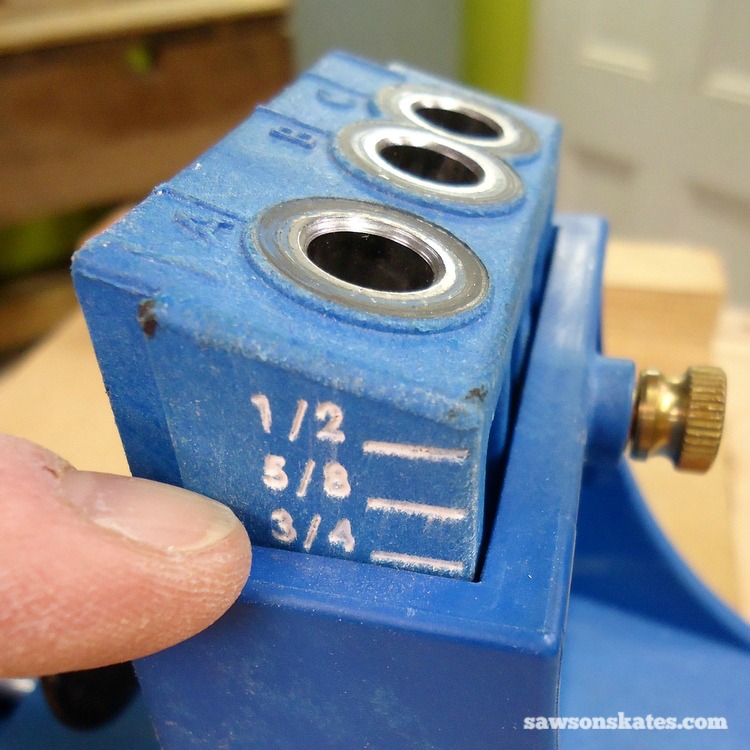

The first step to using the Kreg Jig is to adjust the drill guide to the thickness of your board. If your board is 1-1/2″, set the jig for 1-1/2″. For this example, our board is 3/4”, so we’ll set the drill guide to 3/4”.

Step 2 – Set the Drill

The next step is to set the drill depth. Again, you’ll want to match the drill depth to the thickness of your board. For this example, our board is 3/4”. Loosen the collar with an Allen key and move the shoulder of the drill bit (or the bottom of the stepped area of the drill bit) to correspond with the 3/4” mark and tighten the collar.

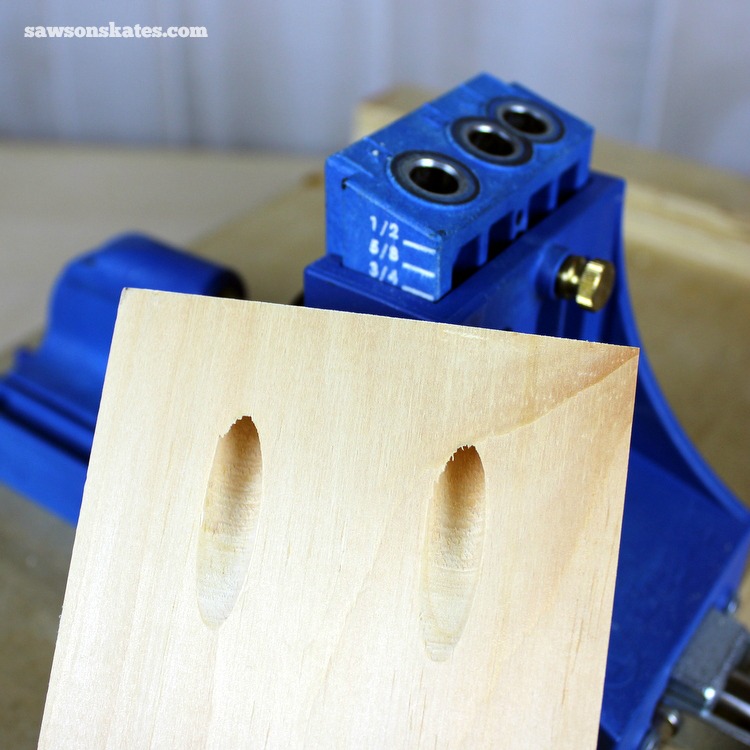

Step 3 – Drill Pocket Holes

Next clamp the board in the jig to correspond with the appropriate drill holes. Chuck the drill bit in your drill and insert the drill bit into the guide block until it hits the wood. Slightly raise the drill bit and bring the drill up to full speed. Then gently lower the bit into the wood and start drilling the pocket hole. Keep drilling until the collar on the drill bit contacts the drill guide.

TIP: For wood that is 1-1/2” wide, center the wood between holes B and C, and drill in holes B and C. For wood that is 2-1/2” wide, center the wood between holes A and B, and drill in holes A and B. Wood that is 3-1/2” wide, center the wood between holes A and C, an drill in holes A and C. For all other widths of wood, make sure your pocket holes are set in a minimum of 3/4” from the edge to avoid possibly cracking the wood.

1. Avoid the End Grain

The most common pocket hole joints we’ll make with our Kreg Jig are butt joints and edge joints.

A butt joint joins the end of one piece of wood to the edge of another piece of wood. Common uses for butt joints are frames for side assemblies and doors.

Related: How to Make DIY Cabinet Doors (Without Special Tools)

An edge joint joins the edges of two boards. Common uses for edge joints are panels and table tops.

Butt Joints

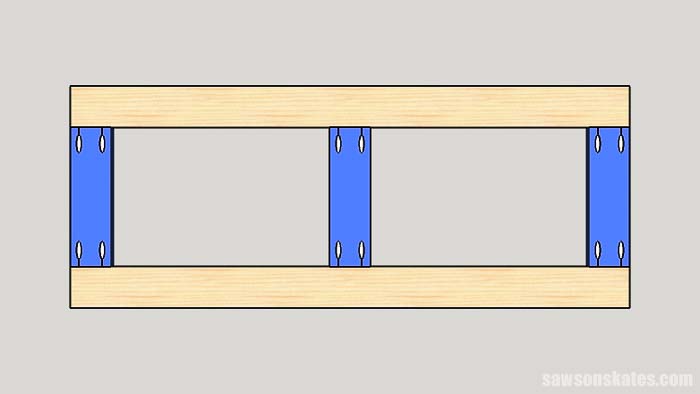

Pocket holes need to be drilled into the ends of a board when creating butt joints. Let’s say we are going to build a frame. We need to drill the pocket holes into the vertical (blue) pieces not the horizontal (wood grain) pieces.

We don’t want to drill pocket holes into the edge of a board (horizontal wood grain pieces) and drive pocket hole screws into end grain because this would not create a strong joint. The grain of wood runs the length of the board. The end of the board is referred to as the end grain.

Think of the wood grain or wood fibers like a box of drinking straws. Imagine driving a screw into the end of a box of drinking straws. What would happen to the screw? That’s right, it would just spin around in the ends of the straws. Driving screws into end grain does not create a strong joint.

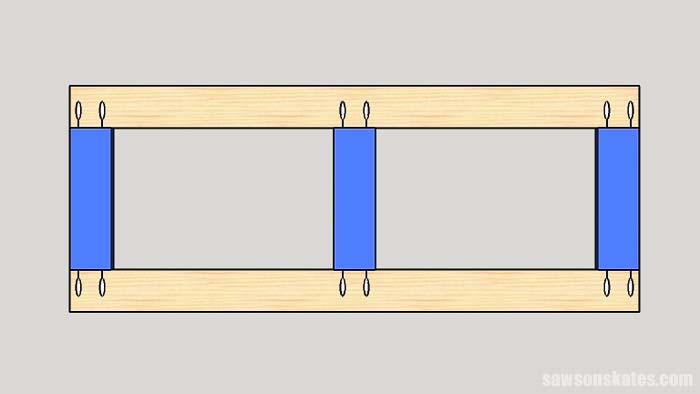

Edge Joints

There’s an exception to every rule, so there is a time when it’s OK to drill pocket holes into the edge of the board and that’s when we are edge joining to make panels, table tops, etc. When edge joining the pocket screw is driven through the edge of the wood and this makes a strong joint.

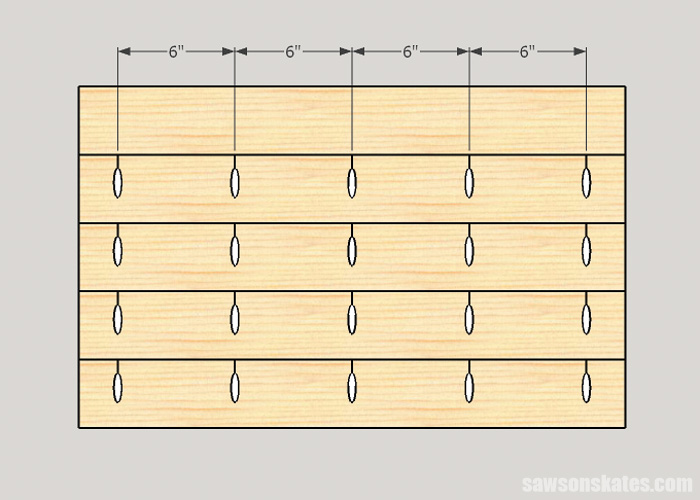

My friend Mike at Kreg Tool recommends setting the pocket holes about 2″ from the ends of a board when edge joining. Mike also recommends spacing pocket holes approximately 6″ apart along the edge of a board.

Skate over to Need to Know Pocket Hole Tips for Edge Joints for more helpful edge joining tips and tricks

2. Change Setup for Different Wood Thicknesses

Many furniture projects use different thicknesses of wood. It’s important to change the drill guide and the collar on the drill bit match the thickness of the wood you’re drilling pocket holes into.

Let’s say you’re drilling pocket holes into a 2×4. You’ll set the drill guide to 1-1/2″ and drill bit collar to 1-1/2″. Then let’s say after you drill the pocket holes into the 2×4 you need to drill pocket holes into 1×4 and you do that without changing the drill guide and drill bit collar. Well, you’ll drill all the way through the end of the board. Not Good! And yes, I have done this on more than one occasion!

How can you prevent this pocket hole mistake from happening? If I’m batch drilling pocket holes, I may use one of my 5 Unexpected Uses for Painter’s Tape tips and label the parts that require different depths of pocket holes.

3. Adjust Drill Bit for Plywood

Plywood, like 3/4″ plywood is actually little thinner than 3/4″. So if you set your drill guide to 3/4″ and drill bit collar to 3/4″, then attach the two pieces of plywood with a pocket screw, the screw will actually poke through the edge of the plywood. Exposed screws are not an attractive look for DIY furniture! Yup, I’ve made this mistake too when I was building the Mid-Century Modern nightstand.

To avoid screws protruding through the edges of your plywood furniture projects set the drill guide to the thickness of the plywood, so for our example, set the drill guide to 3/4″. Then set the drill bit collar, so it’s shallower than the thickness of the wood. For our example set the drill guide between the 1/2″ and 3/4″ mark.

4. Replace Worn Bits

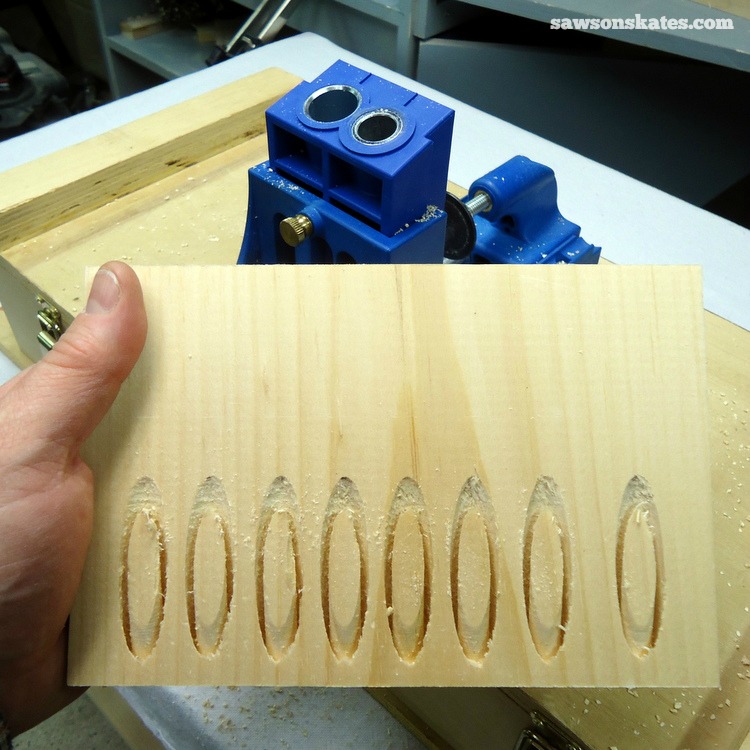

I use my Kreg Jig to drill pocket holes for nearly every furniture project I build. It only makes sense eventually the drill bit would become worn. It’s important to know the signs of a worn drill bit because worn bits drill more slowly, get hot quickly and produce a “fuzzy”, jagged looking pocket hole.

A jagged pocket hole is a particular concern if you’re going to use a pocket hole plug cutter to fill the pocket holes with plugs. With a crisp, clean pocket hole you can place the plug in the pocket hole, sand the plug flush with the surrounding wood and the pocket hole will virtually disappear. With a jagged pocket hole you can place the plug in the pocket hole, sand the plug flush with the surrounding wood, but edges of the pocket hole will still appear jagged. It’s time to replace your pocket hole drill bit if your pocket holes look fuzzy or jagged.

5. Use Wood Glue

Pocket hole joints don’t require wood glue, but that doesn’t mean you shouldn’t use glue when assembling your furniture projects. When a pocket screw is driven through an angled pocket hole it draws the two pieces of wood together tightly. The pocket holes make a strong joint, but it doesn’t take into account the wood itself. Wood is a living thing.

Wait, did I just say wood is a living thing?! Well, not exactly living, but it is hygroscopic. Wait, did I just say hygroscopic – what’s that? Simply put, hygroscopic means it absorbs moisture from the air. Wood is constantly absorbing and giving off moisture, just as it would when it was alive. Remember earlier how I described wood like a box of drinking straws. When the drinking straws, ummm wood, fills with moisture it swells and gets bigger. When it loses moisture it shrinks and gets smaller. If you build a project when it’s humid, you may notice when the air is drier that some of the joints don’t fit as well as it did when there was more moisture in the air.

I’ve noticed this joint issue when edge joining tops for furniture projects. I built my air conditioner dresser in the summer when it was humid, but I didn’t edge glue the top pieces. The top looked great in the summer, but in the cooler months the joints of the top just ever so slightly pulled away from each other. And the edge of one of the pieces even started to slightly curl up.

Can you stop wood movement? The short answer is no, but you can help reduce some of these issues by gluing the joints. If I glued the top of the air conditioner dresser it wouldn’t be moving like it does. Skate over to Mistakes with Wood Can Cause Your DIY Furniture to Crack for more details about the seasonal movement of wood.

Why didn’t I glue the top? Well, I knew I wanted to stain the piece and regular glue doesn’t accept stain. Almost all of us have had a finish ruined by glue squeeze out. The glue squeezed out, we stained the piece and the glue prevented the stain from soaking into the wood. What we’re left with is what looks like a big bleach stain on our project. Regular glue just isn’t stainable. Since then I found Elmer’s Wood Glue Max. This glue creates a strong bond and is stainable.

Pocket holes create a strong, lasting joint, but that joint is made better by adding wood glue.

6. Use Clamps

By now we know how a pocket hole joint works. A pocket screw is driven through an angled pocket hole, and the screw draws the two pieces of wood tightly together. Despite this, you still need to use clamps to properly align the joint before attaching it the joint with pocket screws.

Don’t try to properly align pocket hole joints with your hands. The workpieces will move, and you’ll likely end up with a misaligned, poorly fitting joint.

Nothing beats the mechanical advantage of a clamp. Your pocket hole joints will stay in place, the joints will fit better and your furniture projects will look more professional.

Specifically designed pocket hole clamps are available, but in my How to Prevent Pieces from Moving When Assembling Pocket Hole Joints post I shared that I prefer to use an assortment of bar clamps. This way I can layout the entire assembly, get all of the joints the way I want them, tighten the clamps and attach with pocket screws.

Use clamps when you assemble your pocket hole joints, and the look of your projects will go from amateur to professional.

7. Use Pocket Hole Screws

Pocket screws are specifically designed to work with pocket holes. Pocket screws have threads only on the lower portion, while the upper portion, or shank is not threaded. This design allows the shank of the pocket screw to slide through the pocket hole and pull the joint tight together.

Unlike pocket screws, wood screws have threads along the entire length of the shank. These threads won’t allow the wood screw to slide through the pocket hole. Wood screws may not pull the boards together resulting in a loose-fitting joint. Worse yet wood screws may crack the board.

Use only Kreg brand pocket screws or another authentic pocket screw by another brand to create a tight pocket hole joint.

Pocket Screw Threads

Pocket screws are available in coarse thread and a fine thread. Use coarse thread pocket screws for softwoods like pine, plywood, particle board and MDF. Use fine thread pocket screws for hardwoods like oak, maple, hickory, cherry, walnut and birch.

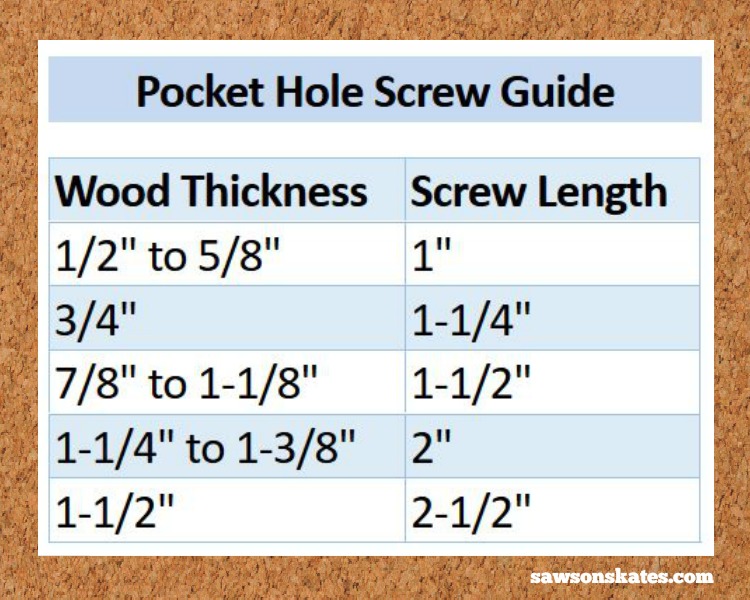

8. Use the Correct Length Pocket Screw

Always use the correct length pocket screw for the pocket hole you have drilled. Using a pocket screw that is too short won’t connect the boards together and using pocket screws that are too long could drive the screw through the edge of the other piece.

TIP: When I use different length screws for a furniture project, I will sometimes write lightly in pencil next to the pocket the length of screw I need to use. Other times I will use painter’s tape to note the length of screw I need to use.

Check out the pocket hole screw guide below to be sure you’re using the right pocket screws for your project.

Kreg Screw Guide

9. Avoid Over Tightening

As we discussed earlier pocket screws are different than wood screws, and that means we have to take a different approach when driving them into the workpieces.

Unlike a wood screw, pocket screws only need to be driven until they’re “just snug” to create a strong joint. Basically we want to stop driving the pocket screw when we start feeling some resistance.

Overtightening a pocket screw can strip the pocket hole which can create a loose joint. Overtightening could even drive the screw through the other workpiece. I set the clutch on my drill to avoid overtightening pocket screws.

Setting the clutch prevents the drill from driving the screw any further when the drill meets a certain amount of resistance. This prevents over tightening and stripping the pocket hole. For driving pocket screws into softwoods like pine my DEWALT drill works well when I set the clutch to 3.

One more thing while we’re chatting about drills. I recommend using a drill for both drilling pocket holes and driving the screws rather than an impact driver. The impact action of an impact driver can loosen the drill bit depth collar when drilling pocket holes and could possibly strip the the pocket hole when driving the screw. Stick with a drill and you’ll be good to go.

Related: Impact Driver vs Drill: What’s the Difference?

TIP: Over tightening a pocket screw is just one way a pocket hole can become stripped. Another way a pocket hole can become stripped is if you remove a pocket screw and then reattach it. Fixing a stripped pocket hole is as easy as grabbing some wood glue and heading to the kitchen for some toothpicks.

Bonus Tip – Make Your Pocket Holes Virtually Disappear

The Kreg Pocket Hole Plug Cutter will take your furniture building to the next level! The plug cutter makes plugs to fill pocket holes. The plugs are cut from leftover scrap wood from your project, so the plugs will exactly match the wood color and wood grain of your project.

The plugs are glued into the pocket holes and then sanded flush. With a pocket hole plug cutter, your pocket holes virtually disappear and you’ll make your DIY projects look more professional. This a “gotta have it” tool for the DIYer! Check out my plug cutter setup tips and video!

Bonus Tip – Secret Weapon For Hard-to-Reach Pocket Holes

It will happen to all of us at some point. We’ll chuck the pocket hole driver in our drill, attempt to drive the pocket hole screw into the pocket hole and… CRASH!!! The drill/driver combo is too large to fit in our DIY furniture project. We can’t tighten the screw. What do we do now? You need my secret weapon I keep in my tool arsenal for hard-to-reach pocket holes – a right angle attachment!

Get Answers to Your Pocket Hole Questions!

If you didn’t find the answer to your pocket hole question in this post or in the Kreg Jig Tips and Tricks directory you can ask your pocket hole questions here!

Download the Pocket Hole Mistakes Guide

Master your pocket hole projects with this FREE ten-page Pocket Hole Mistakes You Don’t Want to Make Guide! The guide includes all of the useful tips in this post plus much more! Just click the link below and I’ll skate over to your inbox with your free guide!

Final Thoughts

Thank you for stopping by to check out my 9 Pocket Hole Mistakes You Don’t Want to Make. Have you made a pocket hole mistake that I didn’t discuss? Tell me about it in the comments. Oh, and if you found this helpful, would you please pin it to Pinterest? I’d really appreciate it! Thank you – Scott

Hi Scott, thanks for the article. I clamped my joints for assembly but one of them still shifted a few mill leaving a slightly wonky connection with a 1-2mm gap at the front. I’m wondering if I should try to redrill or if that will just strip the whole joint as the new hole will be so close to the old one. Unfortunately remaking the piece I’m drilling into isn’t an option.

Hi Claire – Thank you for stopping by. I’m sorry this happened to you. If were working on this project I would fill the hole in the second workpiece with a little glue and toothpick. Then clamp the joint and drive the screw again. The toothpick will fill the hole and give the screw something to bite into.

Thanks very much for your answer! I’ll give that a go.

I would like to make a pocket hole in the middle of a 14” wide board to close a crack in the board. Any suggestions on how to clamp the small jig to the flat board where typical clamps are not deep enough to hold the jig?

The Kreg Jig R3 is great for making repairs. It has a hole in the body of the jig. We can drive a screw through the hole to attach the jig to the workpiece.

This means we don’t need any clamps to attach the jig to a workpiece. And we can position the jig just about anywhere we need to drill some pocket holes.

Check out Tip #4 of my Kreg Jig R3 post for more information.

So no judgement please…I was letting my daughter help me and forgot to adjust the drill bit and she drive through pocket hole A through the plastic. Is this completely worthless now??? Is there a replacement part to the kreg?

Hi Kelly – Thank you for stopping by. No worries here. This is a judgement-free pocket hole zone! And no worries about the holes in your jig. It will still work just as it did before. And if it’s any comfort my jig has holes in it too!