How to Make a DIY Circular Saw Crosscut Jig

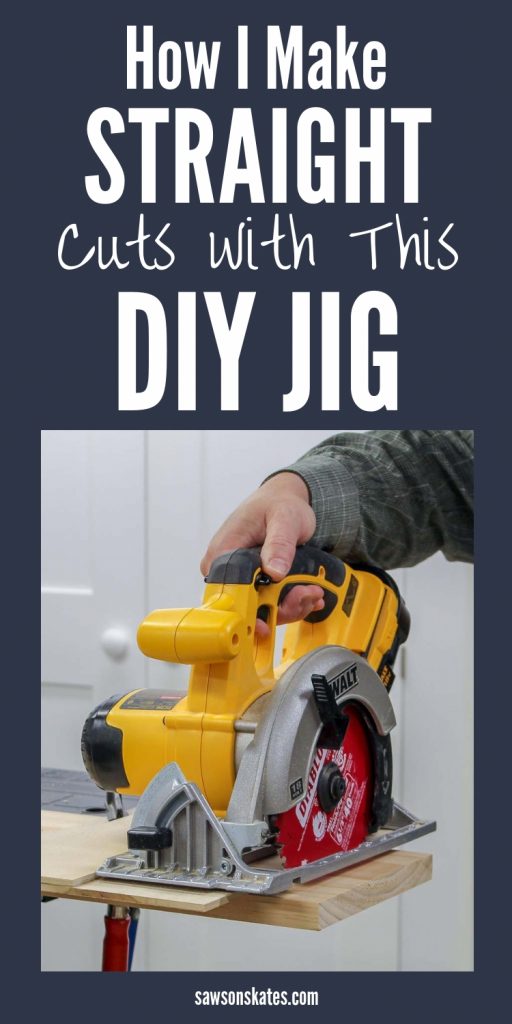

Make a DIY circular saw crosscut jig! This simple cutting guide is perfect for making accurate crosscuts and precise miter cuts with your circular saw.

Circular Saw Crosscut Jig

What should you do when a piece of wood is too wide to cut with your miter saw? Make this simple DIY circular saw guide! It works great for both crosscuts and miter cuts.

I made my cutting guide in about ten minutes using some scrap wood. That means this project was quick, easy and free!

You may also enjoy 4 Ways to Make Straight Cuts with a Circular Saw and How to Change a Circular Saw Blade

Originally published July 4, 2015 updated July 26, 2019

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Before we get into how to make a circular saw crosscut jig, be sure to click the subscribe button at the bottom of this page to sign up for my FREE weekly newsletter loaded with helpful pocket hole tricks, space-saving workshop ideas, clever DIY tips and more!

Table of Contents

Common Circular Saw Cuts

The common types of cuts we’ll make with our circular saw are rip cuts, crosscuts and miter cuts.

A rip cut is made with the grain of the wood or along the length of the board.

A crosscut is made across the grain of the wood or across the width of the board.

A miter cut is made diagonally across the grain of the wood or across the width of the board.

How to Make Crosscuts with a Circular Saw

When we buy a circular saw it generally doesn’t include a fence. A fence or cutting guide helps the saw make accurate cuts. This typically means we need to use the saw freehand.

So how can we make accurate crosscuts with a circular saw? One way is with a speed square.

All we have to do is line up the blade on our cut line and place the speed square on the board. Then we push the base plate of the saw against the square and make the cut.

A speed square works great as long as the cut we need to make is shorter than the length of the speed square. But what if the cut we need to make is longer than the square? That’s where the DIY circular saw guide comes in!

What is a Crosscut Jig?

A crosscut jig helps us make precise crosscuts and miter cuts. It acts like a fence or cutting guide for our circular saw. The base plate of the saw rides against the fence of the jig. The fence forces the saw to make cuts exactly where we want them.

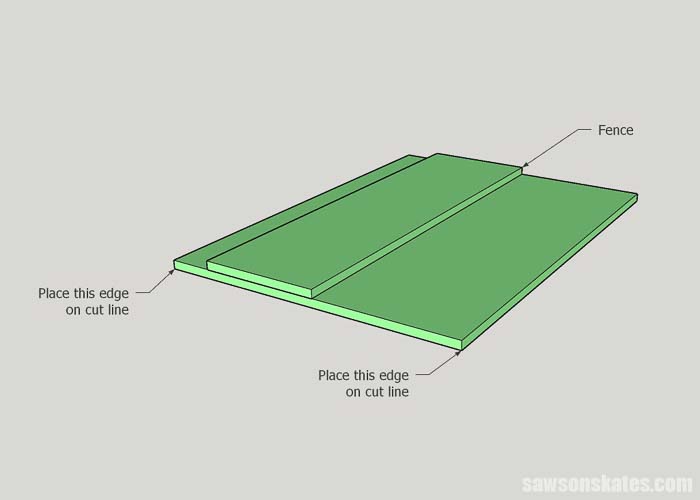

I made my cutting guide in about ten minutes with just two scrap pieces of 1/4″ plywood. You can also use MDF instead of plywood.

The larger piece of plywood acts as a base for the jig. It’s also a guide for the saw blade. The edge of the jig is placed exactly where we want to make our cut.

The narrow piece of plywood is glued to the larger piece. This narrow piece acts as a fence for the base plate of the saw.

NOTE: The circular saw jig can be used on the right side or left side of the saw.

To use the jig we’ll measure and make pencil marks on the board we want to cut. We’ll place the edge of the jig on the pencil marks and clamp the jig to the board. Then, we’ll place the circular saw on the jig. The base plate of the saw will follow the fence. The saw blade will cut along the base of the jig, which is exactly where we want to cut.

How to Make a DIY Circular Saw Crosscut Jig

Supplies

- Wood (per printed plan)

- Wood Glue

Tools

- Tape Measure

- Kreg Multi-Mark

- Circular Saw

- Table Saw

- Spring Clamps

Step 1. Measure the Circular Saw

We need to make two measurements on our circular saw. First, we need to measure from the blade to the left edge of the base plate.

Second, we need to measure from the blade to the right edge of the base plate.

Next, we’ll add these two measurements. Then, well add the width of the fence that we’ll cut in Step 3.

This will be the minimum width for the base of the jig. We actually need to trim a little off the base to make it square (see Step 5), so we need to make the width of the base larger than the minimum width.

Step 2. Make the Bottom

I used my table saw to cut a piece of plywood to size.

Related: Table Saw Safety Rules (Every DIYer Needs to Know)

Step 3. Make the Fence

I used my table saw to cut a piece of plywood to width for the fence.

Step 4. Attach the Fence

Next, I took the narrow measurement of my saw and added about an 1/8”. Then, I set my Kreg Multi-Mark to this measurement.

Next, I applied glue to the back of the fence and used the Kreg Multi-Mark to position the fence on the base.

I used several spring clamps to hold the fence in place.

Step 5. Prepare the Jig for Use

I removed the clamps when the glue was dry. Next, I clamped the jig to my workbench. I placed the base plate of the saw against the fence and trimmed the excess off the base of the jig.

I repeated this step on the other side of the jig. Now the fence is square to each side of the jig and our cutting guide is ready to use.

How to Use the Circular Saw Cutting Guide

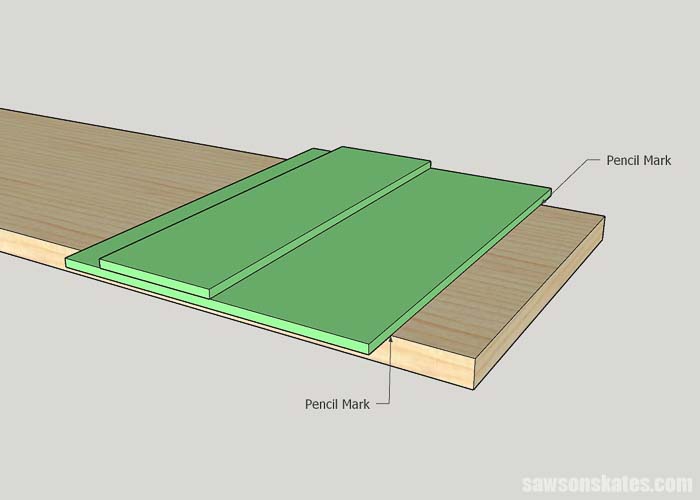

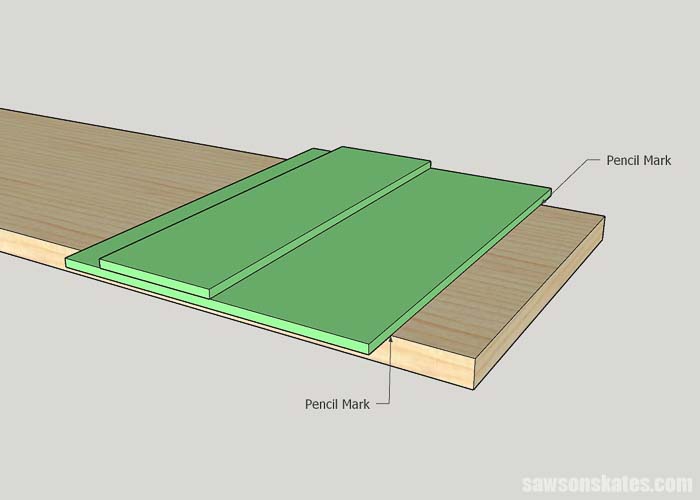

Step 1. Measure the Board

First, we’ll measure and make pencil marks on each edge of the board we want to cut.

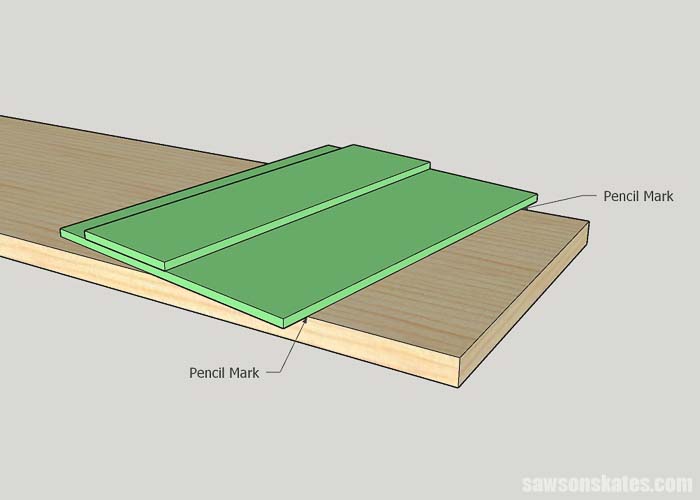

Step 2. Position the Jig

Next, we’ll place the edge of the cutting guide on the pencil marks. I used two small bar clamps to hold the jig in place.

The guide can be used for crosscuts.

And it can also be used to make miter cuts.

Step 3. Make the Cut

Place the circular saw on the jig. Start the saw and make the cut. Be sure to keep the base plate of the saw against the fence of the jig.

The saw blade cuts exactly on our pencil marks.

Final Thoughts

What should you do when a piece of wood is too wide to cut with your miter saw? Make this simple DIY circular saw guide! It works great for both crosscuts and miter cuts.

I made my cutting guide in about ten minutes using some scrap wood. That means this project was quick, easy and free!

Click here to get the free plan (including the detailed instructions and measurements) now!

Thank you for stopping by. If you found this information helpful, would you please pin it to Pinterest? Other DIYers would appreciate it and I would too! Thank you – Scott

Thankyou for the informative article on the cross cut jig . The store versions cost an arm and a leg here in SA.

Hi there – Thank you for stopping by. I’m glad this was helpful for you!

Thanks very simple and easy to follow better than most

Hi Al – Thank you for stopping by and for the compliments!

Thanks, very nice quick and easy design. Used your basic design when replacing my deck boards recently. Saved a lot of setup time cross cutting deck boards to size.

Hi Patrick – Thank you for stopping by. I’m glad the jig was a time-saver and worked well for you!

I like your jig – I have found that sometimes my speed square can move just slightly, and my cut is spoiled, so this makes a lot of sense. I might add one more piece to the jig; I’m thinking that I could glue a piece of plywood at precisely 90 degrees to the underside at the leading edge, which would work well for 90 degree cross cuts. What do you think?

Hi Marc – Thank you for stopping by. Adding a stop to the jig is a great idea. Please let me know if you try it. I would be interested in hearing how it turns out.