Jointer vs Planer (Differences & Which to Buy First)

Choosing between a jointer and a thickness planer can be confusing. I’ll break down the differences, when to use each, and which to buy first.

Do you know the difference between a jointer and a planer? If not, don’t worry! You’re not alone. Many do-it-yourselfers are unsure of the differences between these two woodworking machines.

Both tools have their own unique benefits and drawbacks, so it can be difficult to decide which one is right for you. In this easy-to-understand article, I explain the differences between these two machines and help you decide which one is best for your needs.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Table of Contents

- What is a Jointer?

- What Does a Jointer Do?

- Parts of a Jointer

- Types of Jointers

- Jointer Pros and Cons

- How to Use a Jointer

- What is a Planer?

- What Does a Planer Do?

- Parts of a Planer

- Types of Planers

- Planer Pros and Cons

- How to Use a Planer

- Main Differences Between Jointer vs Planer

- Which is Better a Jointer or Planer?

- Do They Make Jointer-Planer Combos?

- Should You Buy a Jointer or Planer First?

What is a Jointer?

A jointer is a woodworking machine that functions like a hand plane to smooth the surface of boards. There are several key differences between a jointer and a hand plane. A plane is a handheld tool operated without electricity, while a jointer is a power tool.

Jointers have infeed, and outfeed tables with a rotating blade mounted between them. Lumber is passed over the spinning blade to remove small amounts of material, whereas a hand plane is passed over a board.

Lastly, using a hand plane to smooth a board requires skill and is time-consuming, while using a jointer is quick, easy, and nearly effortless.

Jointers may also be used for tasks beyond squaring edges, such as rabbeting, beveling, and chamfering.

Back to Table of ContentsWhat Does a Jointer Do?

Wood jointers are used to flatten one face of a board and square an adjacent edge.

Before we go on, we should talk about the three surfaces of a board: face, edge, and end.

- Face

The face is the widest side of a board and usually the surface that is seen when the board is finished. - End

The end is the surface of the board where the pores are exposed. The pores are like drinking straws used to bring water from the roots to the rest of the tree. - Edge

The edge of a board is the long, narrow side perpendicular to the board’s end.

A jointer is a must-have tool for working with rough-cut lumber. Rough cut lumber has not been milled to its final thickness or dimensions. The surface has saw marks, and it feels rough to the touch.

Additionally, jointers are used to correct defects such as boards that are cupped, bowed, warped or twisted.

By passing the wood over a series of sharp, straight blades mounted beneath the table, a wood jointer creates smooth, flat surfaces and makes edges perpendicular on one side of a board at a time.

To begin, the board is passed over the table or bed that is wider than the width of the wood. To allow for the depth of cut, the outfeed table is set slightly higher than the infeed table.

After the face has been flattened, an adjacent edge may be squared. To produce a straight edge perpendicular to the face, the flat side is placed against the jointer’s fence, which guides the board past the cutter head.

You could also flatten the opposing face and square the opposite edge, but a jointer has a number of drawbacks. The first is that jointers lack the ability to control the finished thickness of a board. In other words, there isn’t a way for a jointer to cut several boards to the same thickness. Furthermore, jointers are unable to ensure that the second face or edge is parallel to the first.

The best method to ensure the second face is flat and parallel to the first is by using a planer. The best way to ensure the opposite edge is straight and parallel to the first is to use a table saw.

To flatten the opposing face, the flat face of the board is placed on the bed of the planer and passed under the planer’s cutter head to create faces that are parallel.

To square the opposite edge, the board is placed on the table saw with the flat face against the table and the squared edge against the fence. The board is passed through the blade to create edges that are parallel.

Why is it Important to Flatten Faces and Square Edges?

When it comes to producing tight fitting-joints and professional-looking results, it’s important to use boards with smooth, flat faces and square edges.

Lumber with flat faces and square edges is easier to join, whether making a basic butt joint or gluing up boards to make larger components. When making panels, tabletops, desks, shelves, among other things, squared edges are essential to ensure there are no gaps between the boards.

Back to Table of ContentsParts of a Jointer

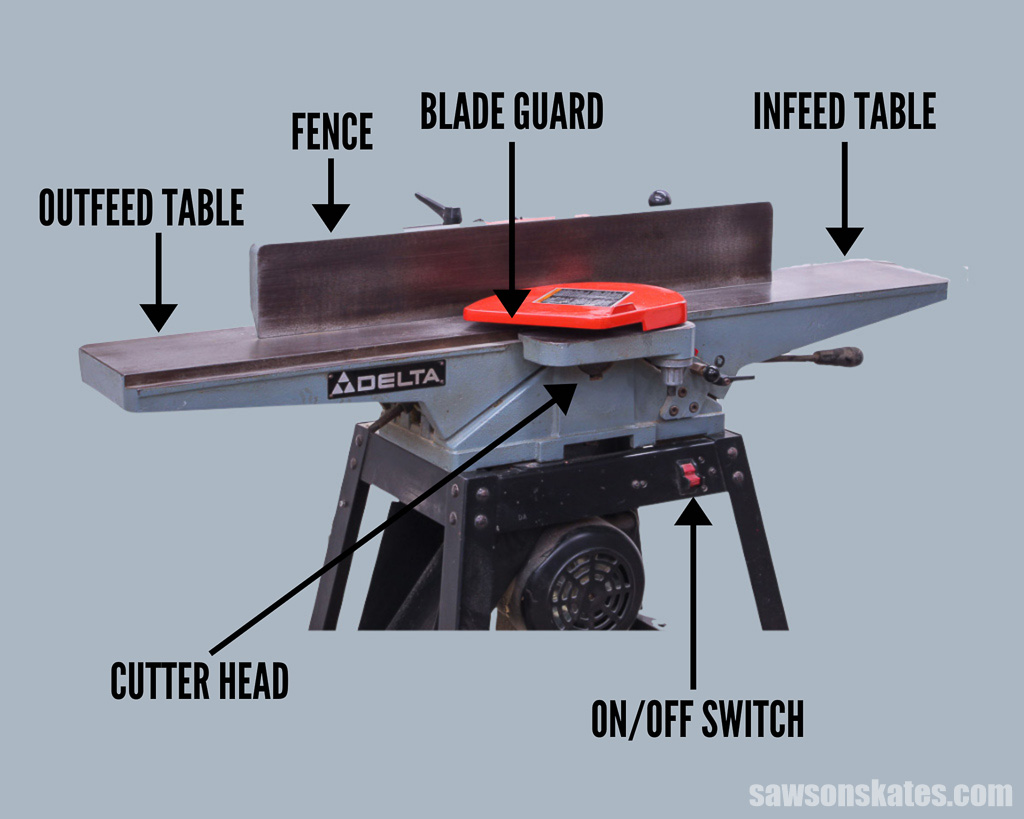

The five main parts of a jointer are the infeed table, outfeed table, blade guard, cutter head, and fence.

Infeed Table

The bed of a jointer is made up of two adjustable tables. The first is the infeed table, which receives the workpiece. The workpiece is positioned on the infeed table and pushed across the cutter head to the outfeed table. The infeed table may be raised or lowered to control how much material is removed from the workpiece.

Raising the infeed table exposes less of the cutter head, which removes less material. Lowering the table exposes more of the cutter head and increases the amount of material removed.

The height of the infeed table will depend on how much material you want to remove with each pass.

For softwood, no more than 1/8” should be removed in a single pass, while for hardwood, no more than 1/16” should be removed.

Infeed Height Adjustment

A jointer’s infeed height adjustment controls the height of the workpiece at the cutter head and determines how much (or how little) material is removed with each pass.

Outfeed Table

The outfeed table is the second part of a jointer’s bed. When properly adjusted, the surface of the outfeed table is perfectly flush with the tips of the jointer’s knives at their topmost point of rotation, which is known as top dead center (TDC).

After passing over the cutter head, the outfeed table supports the workpiece at the same height it was milled, ensuring that the workpiece is flat.

It’s essential that the infeed and outfeed tables are parallel to each other across their length and width; otherwise, the jointer will not produce boards with flat surfaces.

Outfeed Height Adjustment

A jointer’s outfeed height adjustment controls the height of the workpiece after it passes over the cutter head.

Blade Guard

The blade guard is a spring-loaded, pivoting cover mounted over the cutter head to protect you from coming into contact with the spinning knives.

The guard pivots to the side as a workpiece passes over the cutter, then automatically returns to its original position when the workpiece exits the cutting area.

Cutter Head

The cutter head is a rotating drum located below the blade guard. It contains two or three sharp knives and spins at speeds between 5000 and 6000 RPMs.

A jointer’s cutter head is the most important part of the machine. It’s what does all the cutting.

Adjustable Fence

Jointers have a tilting fence that is typically set at 90 degrees to the table for squaring an edge to a flattened face, but it can also be tilted to different angles to produce a bevel or chamfer on a workpiece’s edge.

Fence Tilt Handle

The tilt handle adjusts the angle of the fence and locks it in position.

On/Off Switch

The switch turns the jointer on and off.

Dust Port

The dust port is where the wood chips exit the jointer. The amount of chips and dust created by a jointer can be overwhelming. To help control the mess, the port is usually connected to a ShopVac or dust collection system that collects the waste. Some jointers do not include dust ports and need to be purchased separately from an online retailer.

Back to Table of ContentsTypes of Jointers

The two common types of jointers are benchtop and cabinet-style.

Benchtop Jointer

For do-it-yourselfers, a benchtop jointer is a popular choice. They are small enough to use on a workbench and light, making them easy to transport and store. Benchtop jointers are ideal for woodworkers who don’t need the power of a bigger, more expensive cabinet-style jointer.

Cabinet-Style Jointer

A cabinet-style jointer, also known as a floor-standing jointer, is a popular choice for serious woodworkers. They are larger, stationary machines with more power and the ability to mill wider width boards than benchtop jointers.

Back to Table of ContentsJointer Pros and Cons

Pros

- Quickly and easily flattens surfaces and squares edges

- Requires less time and effort than using a hand plane

- Corrects common wood defects such as warped, cupped, bowed, or twisted boards

- Fence can be adjusted to create square edges, bevels, or chamfers

Cons

- Lacks the ability to control the finished thickness of a board

- Unable to ensure that the second face or edge is parallel to the first

- Requires additional tools like a planer and table saw to adjust the thickness of a board and square the second edge

How to Use a Jointer

Here’s a helpful video that shows how to use a jointer.

What is a Planer?

A thickness planer, also known as a thicknesser or simply a planer, is a woodworking machine used to smooth and reduce boards to a uniform thickness across their length. In a nutshell, a planer makes thick boards thinner.

A wood planer functions like a hand plane to smooth the surface of boards, but there are a few key differences between them. A plane is a handheld tool operated without electricity, while a planer is a power tool.

Planers have flatbed with cutter head mounted above. Rollers feed the workpiece across the bed and under the cutter head, which removes a layer of wood as it passes through the machine.

Planers have settings that can be used to ensure a uniform thickness along the length of a board. While getting a uniform thickness with a hand plane is possible, it requires a significant amount of time, effort, and skill.

Back to Table of ContentsWhat Does a Planer Do?

A thickness planer is used to:

- Smooth rough lumber

- Makes a board’s second face parallel to the opposing face

- Reduce boards to the exact, uniform thickness

After using a jointer to flatten one face, a planer is used to smooth the opposing face and create parallel surfaces.

First, the face of a board flattened by the jointer is placed on the planer’s infeed table. The board is fed through the planer at a constant speed by infeed and outfeed pressure rollers.

A cutter head that spans the width of the bed is mounted above. The cutter head has a series of sharp, straight blades that remove material to create a smooth, flat surface with a uniform thickness parallel to the opposing face.

The cutter head may be raised or lowered to control how much or how little material is removed.

Once a board has parallel faces, planers may be used to reduce it to the exact thickness you want for your project. For example, you may have a board that is 1/2″, but you need a board that is 3/8″. You can use the planer to remove small amounts of material from the board until it’s the desired thickness.

With your thickness setting dialed in, you can feed multiple boards through the planer to mill them all to the same thickness.

Although the benefits of a planer are appealing, it also has some drawbacks. Because the rollers apply pressure to workpieces, planers can’t correct imperfections like warped, cupped, bowed, or twisted boards. In other words, you’ll need to use a jointer first to make the board flat before using a planer.

Parts of a Planer

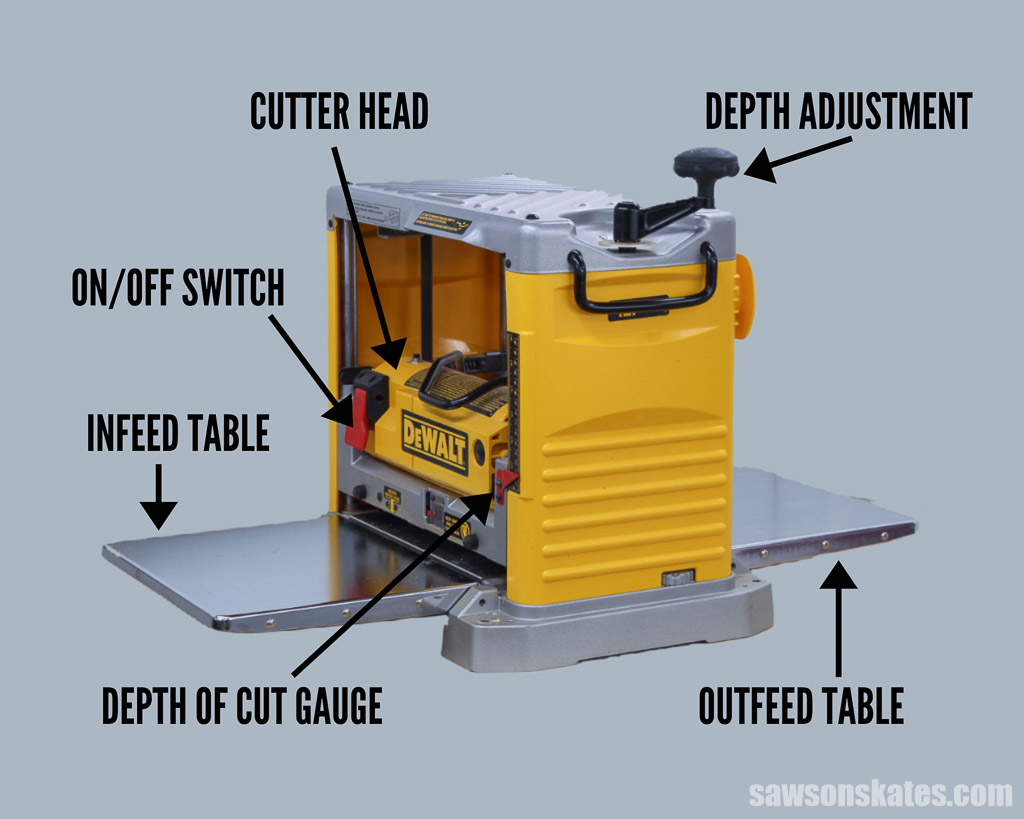

Depth Adjustment

A planer’s depth adjustment knob raises or lowers the cutter head. The lower you set it, the more material will be removed from the board as it passes through.

Infeed Table

The infeed table is the flatbed on which the board is placed before it’s fed into the planer, and should be level with the outfeed table to ensure a smooth, consistent feed of material through the machine.

Outfeed Table

The outfeed table, which is level with the infeed table, is located at the end of the planer and is used to support the board as it exits the machine.

Cutter Head

The cutter head is located above the infeed and outfeed tables and spans the width of the bed. It has a series of straight blades that remove material from the board to create a smooth surface with a uniform thickness.

Depth of Cut Gauge

A planer’s depth of cut gauge is used to set the depth of cut. The gauge is located on top of the cutter head and shows how much material will be removed from a board as it passes through.

Dust Collection Port

A dust collection port allows you to connect your planer to a vacuum or dust collector so that shavings can be collected instead of falling onto the floor.

On/Off Switch

A planer’s on/off switch turns the machine on and off.

Back to Table of ContentsTypes of Planers

Benchtop planers and floor models are the two most common types of thickness planers. Small electric handheld planers are also available.

Benchtop Planer

Benchtop planers are a popular choice for DIYers because of their low cost and small size. They are compact enough to use on a workbench and light, making them convenient to transport and store. Benchtop planers are excellent for woodworkers who don’t require the industrial strength of a larger, more expensive floor model planer.

Floor Model Planer

A floor model planer is a popular choice for serious woodworkers. They are larger, stationary machines with more power than benchtop planers.

For serious woodworkers, a floor model planer is a popular alternative. They are bigger, stationary machines that are more powerful than benchtop planers.

Electric Handheld Planer

Handheld planers are most useful when the wood can’t be passed through the planer because it’s stationary or because of its size, weight, or unusual shape.

They may be used to smooth boards and remove material, but handheld planers lack the ability to create a uniform thickness across the length of a board.

Back to Table of ContentsPlaner Pros and Cons

Pros

- Smooths and removes blemishes from the surface of boards

- Makes a board’s second face parallel to the opposite face

- Reduces boards to uniform thickness

Cons

- Cannot correct defects such as warped, cupped, bowed, or twisted boards

- Cannot square the edges of lumber

How to Use a Planer

Here’s a helpful video that shows how to use a planer.

Main Differences Between Jointer vs Planer

Jointers and planers both smooth and flatten wood, but each has strengths and weaknesses that make them better suited for specific jobs.

A physical difference you’ll notice is a jointer’s cutter head is mounted below the workpiece, while a planer’s cutter head is mounted above the workpiece.

But one of the most significant differences is that a jointer makes one face of a board flat, while a planer makes the opposing face of the board flat and parallel to the first.

Although a jointer and planer perform different tasks, they are also complementary tools. To put it another way, you’ll frequently need to use both machines to achieve your desired result.

For example, let’s say you bought some rough cut wood from a sawmill. In this situation, you’ll need to use both machines to prepare the wood for your project. First, you would use the jointer to flatten one face. Then, you would use a planer to make the opposing face parallel with a uniform thickness.

Another difference is a jointer can square lumber by making the board’s face and adjacent edge perpendicular to each other, as opposed to a planer that can only make the board’s faces parallel.

Planers reduce boards to an exact, uniform thickness, while jointers lack this capability.

Jointers can correct boards with cups, bows, warps, or twists, whereas planers don’t have the ability to remove these imperfections.

As you can see, neither a jointer nor a planer can perform all tasks. As a result, serious woodworkers typically have both machines in their workshops.

Back to Table of ContentsWhich is Better a Jointer or Planer?

As I mentioned earlier, a jointer and a planer each have specific advantages that make them better suited for certain tasks, so the answer of which is better will depend on the goals of your woodworking project.

You’ll want to consider: What type of project are you working on? Do you plan to use rough cut wood from a sawmill, or will you use dimensional lumber from a home improvement store?

A jointer would be helpful if you plan to use rough cut lumber. If you just need to reduce the thickness of dimensional lumber, a planer might be all you’ll need. But again, many times you’ll need both machines to get the best results.

That said, many woodworkers believe that you’ll be able to accomplish more with a planer than a jointer. This is because other tools have the ability to do the same work as a jointer.

For example, a router sled can be used to flatten one face of a board. A router sled or planing sled is a jig with a bridge that supports a router and slides on two runners.

The workpiece is positioned below the bridge. The router is fitted with a flattening bit and pushed back and forth on the bridge (almost like an old-school dot matrix printer) to flatten the top of the board.

There are several options to square a board’s edge, such as a router table, a circular saw and guide, or a jointing jig and table saw. You may also make jigs for a planer that accomplish the same functions as a jointer.

Related: How to Use a Router Table for Beginners

Back to Table of ContentsDo They Make Jointer-Planer Combos?

Yes, a jointer/planer combination machine has the ability to convert from a jointer to a planer and uses one cutter head to perform both tasks.

The advantage is single jointer/planer combination machine takes up less room than an individual jointer and planer. However, changing the set up from one to the other takes time, making a combo machine less convenient than having a separate jointer and planer. Also, some combination machines might be too costly for many DIYers.

Back to Table of ContentsShould You Buy a Jointer or Planer First?

When it comes to purchasing a jointer and a planer, the cost is undoubtedly a factor. As a result, most of us will be able to afford only one at a time.

If you must choose between these tools, there are some things to consider. The most important determining factor is which one gives you the most value for your money.

In my view, a thickness planer delivers the best bang for your buck and should be the tool you buy first. When I started woodworking, I bought a new thickness planer years before buying a jointer.

Earlier in this article we learned many woodworkers feel that you can do more with a planer than a jointer.

A jointer does two things really well: it makes one face flat and makes one edge square to that face. Jointers can’t make the opposing face parallel to the first, and they can’t reduce boards to an even thickness.

On the other hand, a planer has more functionality than a jointer. First, with a planer, you can buy off-the-shelf lumber from a home improvement store or lumberyard and reduce the boards to any thickness you need.

If you want to work with rough cut lumber instead, you could also make some DIY jigs for a planer that performs the same tasks as a jointer. Or you could use other tools like a planing sled and router, a circular saw and guide, or a jointing jig and table saw to prepare the lumber for your project.

These alternatives are not as efficient as using a jointer, but they will get the job done until you save enough money for one. There’s no need to spend extra money on a jointer until then.

Back to Table of ContentsFAQs

Can You Use a Planer as a Jointer?

Yes, by building a few clever jigs, a planer may be used as a jointer. One face of a board can be flattened using a planing jig or planing sled, just like a jointer.

A planing sled is constructed from a flat piece of material like MDF. A stop, which is shorter than the board’s final thickness, is mounted at the back edge of the sled. The workpiece is positioned on the sled, and any gaps between the board and sled are wedged with shims to keep it steady. As the workpiece passes through the planer, it’s held in place by the stop.

After the high points are removed and the face is flat, the workpiece is taken off the sled and passed normally through the thickness planer to flatten the opposing face.

Here’s a short video which explains how to do it.

You may also use a planer and an edge jointing jig to square the edges of boards.

Like a planing sled, an edge jointing jig is made from a piece of flat material and has a stop at the rear to keep the workpiece in place. The top of the sled has stops mounted to prevent the workpiece from rocking side to side.

The board is placed on the sled, and any spaces between it and stops are wedged with shims to keep it steady. The stops hold the workpiece in place as it travels through the planer.

When the high points are removed and one edge is square, the workpiece is removed from the sled and run normally through the planer to square the opposite edge.

Here’s a short video showing you how to do it.

Can You Use a Table Saw as a Jointer?

Yes, you can use a table saw to square the edges of a boards.

Here’s a video showing just one way a table saw can be used to joint edges.

Final Thoughts

A jointer is useful for flattening boards and squaring their adjacent edges, while a planer is excellent for thicknessing boards. If you are a beginner woodworker, I recommend starting with a planer because it’s more versatile than a jointer.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

This is exactly the information I have been looking for! Answered so many questions for me! Thank YOU! Wish I could be your apprentice!

You’re welcome, Sheryl. Thank you for the compliments. I’m glad it was helpful for you.

If you do a lot of projects using pallet boards, you’re going to need a planer and a jointer. Pallet wood is wonderful since it’s free and usually a hardwood. But 90% if it is rough cut. Some of it VERY rough cut.

Hey Scott,

As an English major I can say that your explanations are beautifully done, accurate, and very concise and complete!!! Well Done!!!! I appreciate the videos you selected too. They did a fine job of explaining how these two machines are used. This has to be one of the best treatments on this topic, and that is saying a lot!!

Thank you so much for the compliments! You made my day!!!