DIY Flip Top Workbench Cart

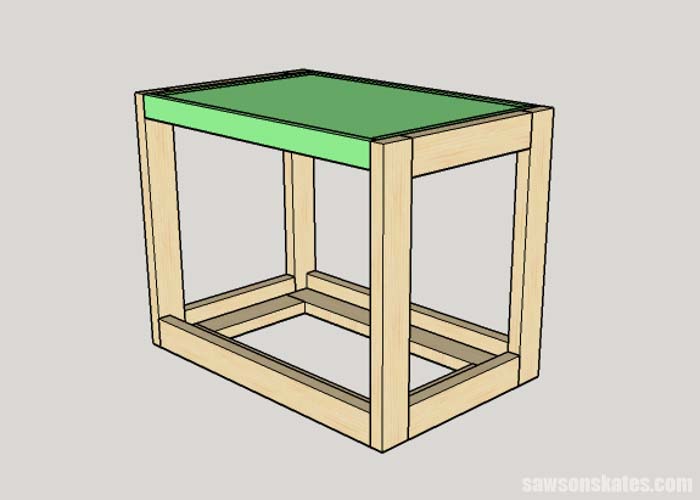

Hey friends! Today I’m sharing new DIY workshop plans for the perfect space saving solution for your small workshop – a DIY Fliptop Workbench Cart. You know space is always at a premium in a small shop and a popular space saving project is a fliptop cart. Oh, you’re not familiar with a fliptop cart? Tools, like a miter saw or small table saw, can be mounted on one side, then the top can be flipped and the cart can be stored out of the way to maximize floor space.

Most fliptop carts are made with plywood. Just like you know space is always at a premium, you also know dealing with plywood in a small workshop is nearly impossible. Not to mention if you have a small vehicle, getting the plywood home can be like stuffing sumo wrestlers in a Smart Car!

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

This easy-to-build DIY 2×4 Fliptop Workbench Cart is not only a space saver, but uses only two small sheets of plywood. Let me tell you about its multi-tasking capabilities before I get into the construction details.

You can mount a tool, like a miter saw on one side, then flip the top and the other side reveals a sturdy workbench. It’s like two pieces of shop furniture in one! And this being Saws on Skates, of course the fliptop workbench is mobile. It’s set on top of four locking casters, so you can move it any where you need it.

Now some details about the construction. This DIY fliptop workbench cart is made almost entirely with 2x4s which is a little different than most flip carts.

Related: DIY Power Tool Stand (made with 2x4s)

The fliptop is made with two sheets of 2×4 plywood. These small sheets are way more manageable in a small workshop. Sure, you could have your big box home improvement store cut down a sheet of 4×8 plywood, but where do you store the extra plywood in your small shop? That’s another whole problem! For me, I’ll stick with the small sheets.

Related: How to Decide What Scrap Wood to Keep

By now you are thinking of two questions… doesn’t it take longer to build using 2×4’s and won’t it cost more to build if you’re not using plywood? The quick answers, yes and yes. So yes, there are few trade offs for this DIY fliptop workbench cart. But there are always trade offs when working in a small shop.

I’m guessing there is a little more assembly time due to cutting the 2×4’s and joining them together. But the trade off is I can much more easily work with 2×4’s in my small workshop over plywood.

Related: 9 Clever Ways to Make Your Small Workshop Feel Bigger

I didn’t price this out building exclusively with plywood, but my gut tells me this version probably costs a few bucks more than a plywood equivalent. Again, the trade off of is the extra expense far outweighs the aggravation of dealing with big sheets of plywood in my small shop.

Related: My 12×13 Small Woodshop Layout

Question about cart…

I received an email about the Fliptop Workbench Cart and I thought others could benefit, so I’m sharing the question and my response here. Have I told you how much I love your comments and email messages? Well, I do! I always appreciate and answer questions, so keep ’em comin’!

“Thank you for your awesome website. I am particularly interested in your fliptop workbench cart. Will it be able to handle another tool on the other side?”

This is a great question! I would say depending on the weight of your tools, the DIY fliptop workbench cart should be able to handle a tool on both sides.

The tool I have mounted on one side weighs about 80 pounds and the top flips easily. Let’s say you wanted to mount a miter saw and table saw. I did a little research… I found a basic miter saw that weighs 35 pounds and a basic table saw that weighs 50 pounds, for a total of 85 pounds, so that should work on the DIY fliptop workbench cart.

Just a word of caution… if your gut says “this feels unsafe” than it’s probably unsafe. In other words, don’t put a really heavy tool on one side or both sides and then expect the top will flip easily or safely. I don’t want anyone out there getting crushed! Keep your saws on skates, not on your torso!

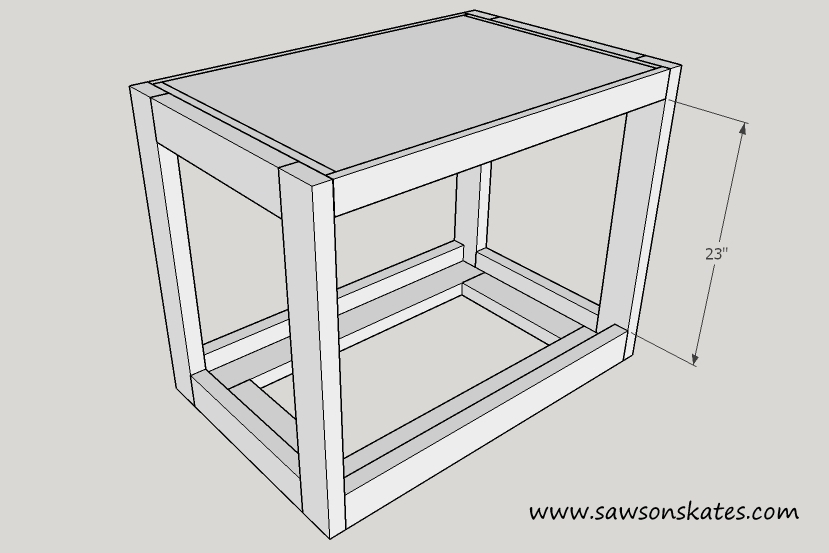

The other thing to consider is the height of your tools. The area inside the cart is 23″, so you want to be sure that your tools are no taller than 23″ or the top won’t be able to flip inside the cart. Below is a pic, so you can see what I’m talking about.

UPDATE: How Did the Fliptop Workbench Cart Hold Up?

It’s been a few years since I built the fliptop workbench cart. How did it hold up? Would I build it again? What would I do differently? Skate over to How the DIY Flip-Top Cart is Holding Up 2 Years Later and I’ll answer all of these questions, plus a few more.

DIY 2×4 Fliptop Workbench Cart Plan

Printed Plan

Click here to get the FREE Plan (including detailed instructions and measurements)

Supplies

Wood (per the printed plan)

Wood Glue

(4) 3″ locking casters

(4) 2″ barrel bolts

#8 3″ wood screws

#8 1-1/4″ wood screws

#8 1″ wood screws

1-1/4″ pocket screws

2-1/2″ pocket screws

(2) 3/8″ 4″ carriage bolts

(2) 3/8″ nylon lock nuts

(6) washers

(4) 1/2″ x .385 x 1″ nylon spacer

Tools

Miter saw

Kreg Jig

Drill

Circular Saw or Jig Saw

Circular Saw jig

Kreg Multi-Mark

Countersink drill bits

1/2″ Forstner Bit

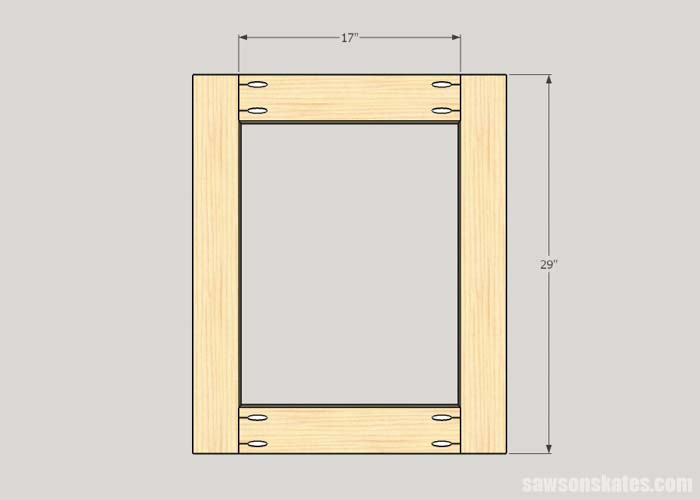

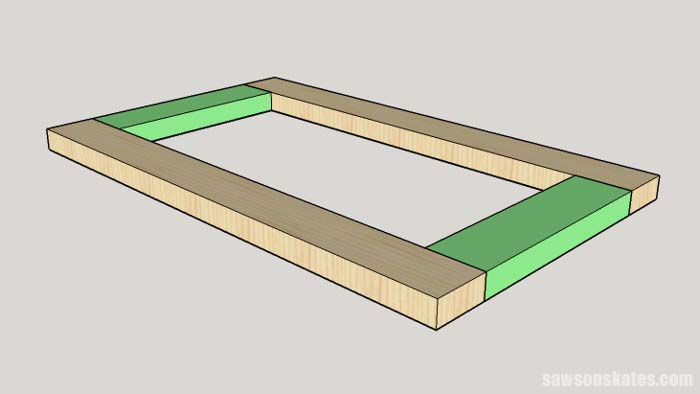

Step 1. Assemble the Sides

Cut the wood for the sides to length and drill pocket holes. Apply glue, clamp, and attach using pocket screws.

Related: How to Use a Kreg Jig

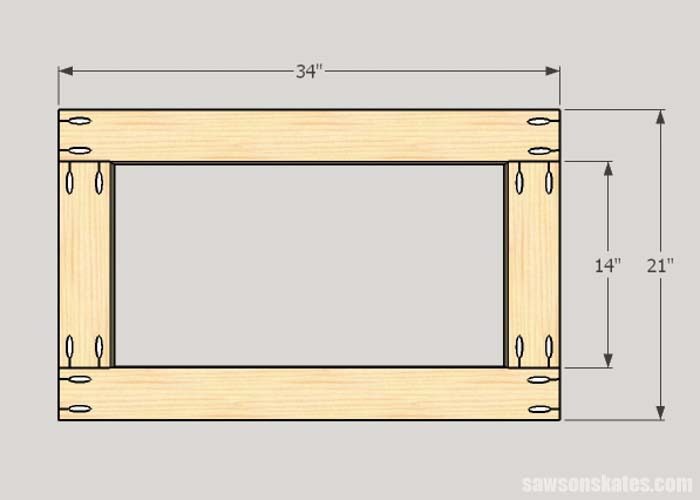

Step 2. Cut the Bottom Pieces and Side Rails

Cut the wood for the bottom to length and drill pocket holes.

NOTE: The bottom assembly (including the side rails) must be the same dimension as the side assembly.

Measure the side assembly (Step 1). Dry fit the bottom pieces and side rails and measure. Adjust the measurements if necessary.

Drill pocket holes in the ends of all of the bottom pieces and side rails. The pocket holes in the short bottom pieces will be used to join to the long bottom pieces in Step 3. The pocket holes in the side rails will be used in Step 4. The pocket holes in the long bottom pieces will be used in Step 5.

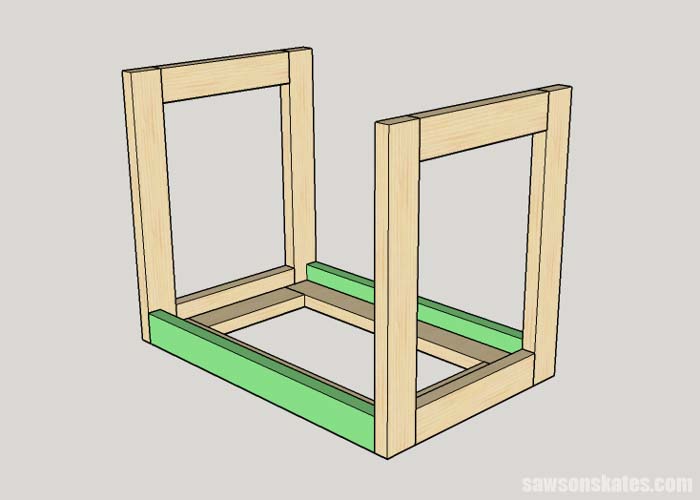

Step 3. Assemble the Bottom

Apply glue, clamp, and attach using pocket screws.

Step 4. Attach the Side Rails

Place the bottom, side rails and side assemblies on your workbench.

NOTE: Do not attach the bottom assembly at this point.

Apply glue only to the ends of the side rails, clamp and attach only the upper pocket screw of the side rail. Gently remove the bottom and attach the lower pocket screws in the side rail.

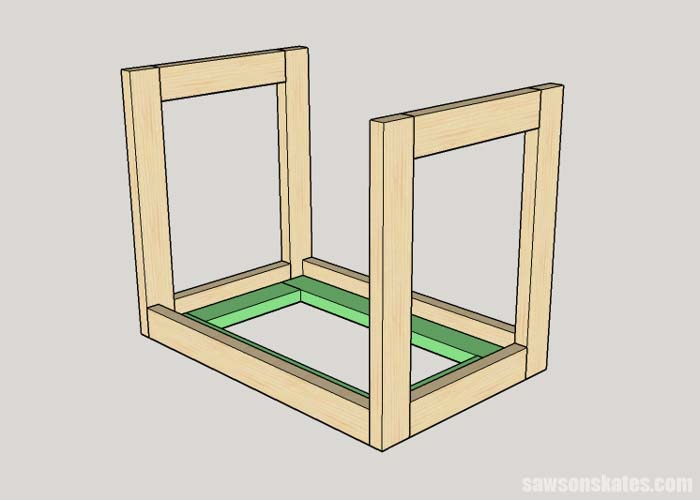

Step 5. Attach the Bottom

Apply glue to the sides of the bottom assembly, place in position and clamp. Be sure the bottom is flush with the bottom of the side assemblies and side rails.

Drill countersink holes in the side assemblies and side rails. Attach to the bottom assembly using wood screws.

Flip the piece over and attach the long bottom pieces to the side assemblies using pocket screws.

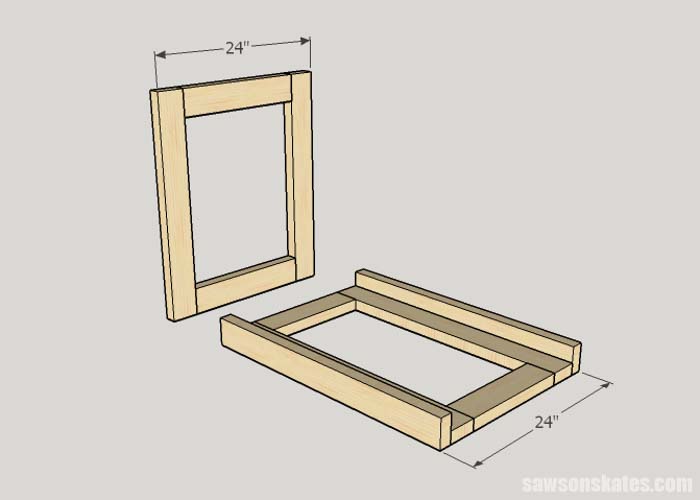

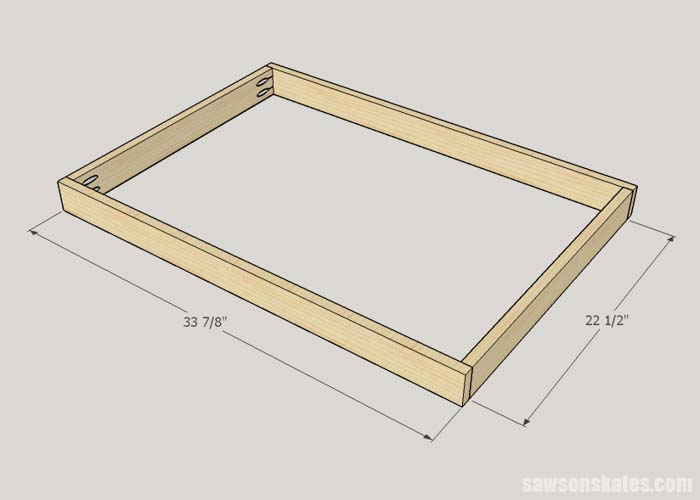

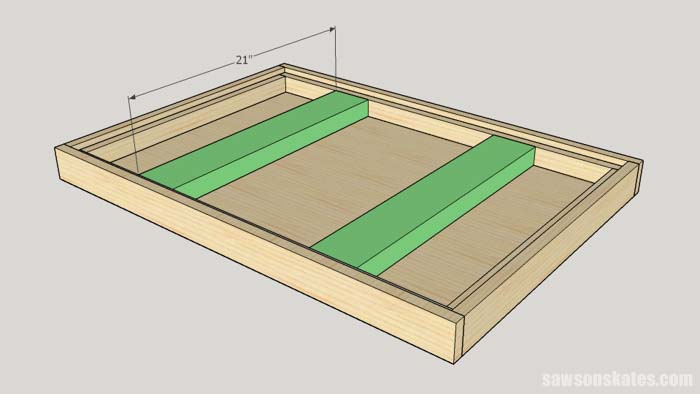

Step 6. Assemble the Table Frame

Cut the wood for the table frame to length and drill pocket holes. Apply glue, clamp, and attach using pocket screws.

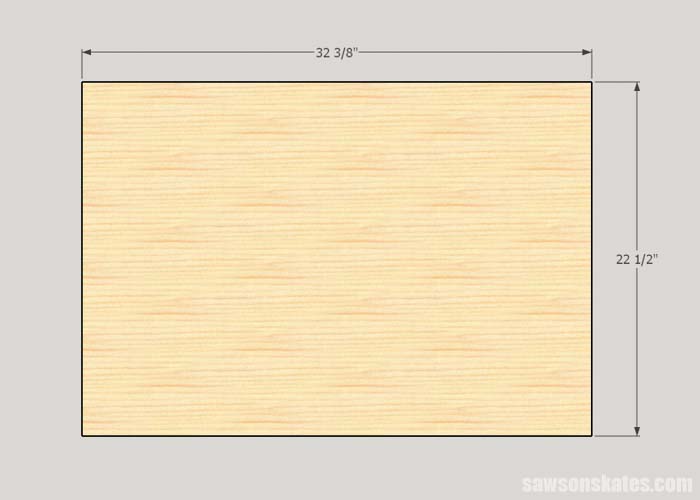

Step 7. Cut the Table Top

Cut 2 pieces of plywood for the table top. Check the inside dimensions of the Table Frame (Step 6) and adjust if necessary.

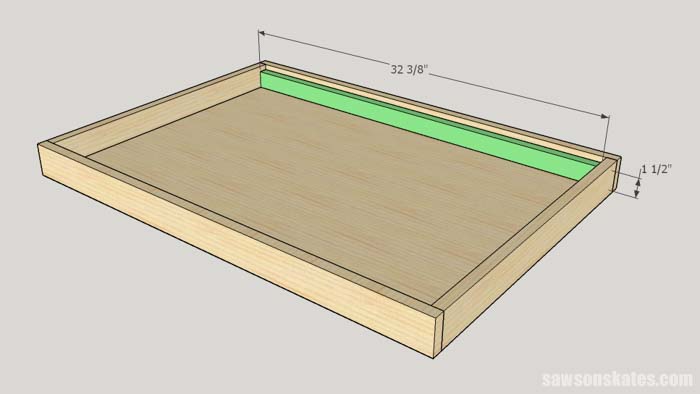

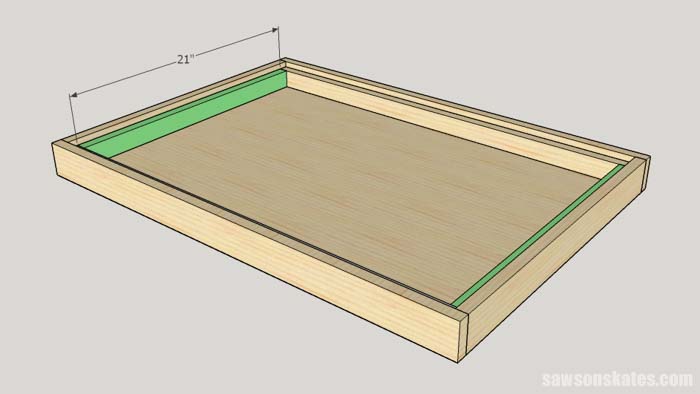

Step 8. Assemble the Inside of the Table Frame

Place one of the plywood pieces (Step 7) inside the table frame. Cut 2 pieces of wood to length, apply glue and clamp to frame.

Flip the frame over and adjust the interior frame pieces, so the plywood is flush with the edges of the Table Frame and tighten the clamps.

With the plywood flush with the edges, flip the frame over again. Drill countersink holes in interior frame pieces and attach using wood screws.

NOTE: Do not attach the top at this time.

Cut 2 pieces of wood to length, apply glue, and clamp to frame. Drill countersink holes and attach using wood screws.

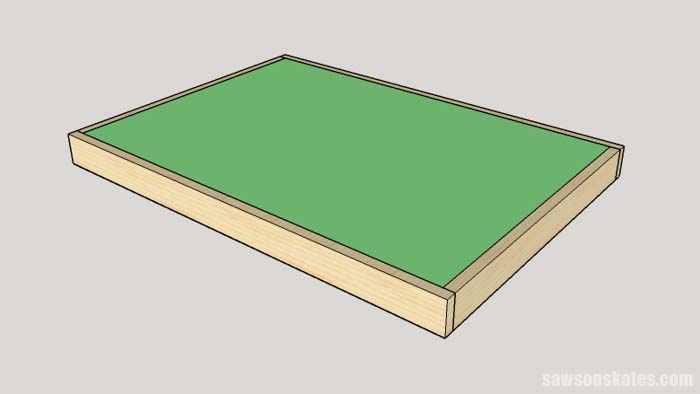

Step 9. Attach the Top

Apply glue to edge of the interior frame, place the plywood on the ledge and clamp. Drill countersink holes around the edge and attach using wood screws.

Step 10. Attach the Table Supports

Cut 2 pieces of wood to length and drill pocket holes in each end. I positioned these supports to correspond with the mounting holes in the thickness planer I was planning to attach to the cart.

Position the supports to correspond with the mounting holes of your tool, apply glue, and clamp. Attach using pocket screws.

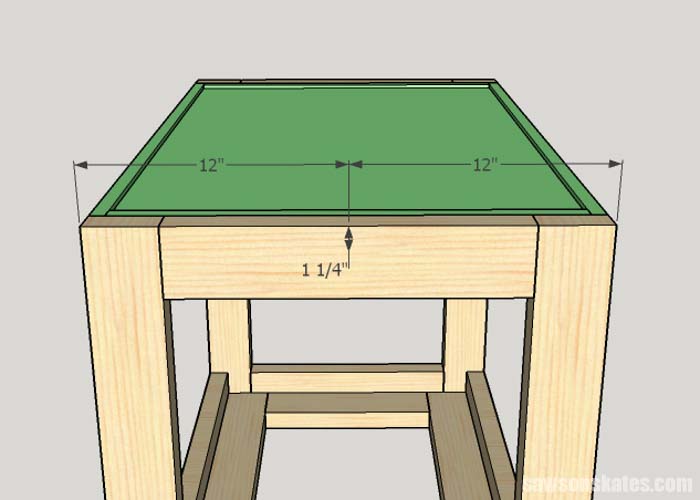

Step 11. Connect the Table to the Sides

Clamp pieces of scrap wood on the inside of each side assembly and flush with the top of the side. Directly below this scrap wood, clamp an additional piece of scrap wood and then remove the first piece of scrap wood. This will serve as a temporary ledge to install the top.

Set the top on the temporary ledge and clamp the top to the sides.

Make a mark in the middle of the side assembly and measure down. Use a Forstner bit to drill through the side and through the table top. Repeat on the other side.

Leave the temporary ledge in place. Remove the clamps holding the top to the sides and remove the top. Insert a nylon spacer into each of the holes you just drilled in the sides and in the top.

Insert a carriage bolt into the side until it protrudes just enough to insert a washer, replace the top and push the carriage bolt through the top, add two more washers and attach with a lock nut. Repeat on the other side.

Step 12. Attach the Barrel Bolts

With the temporary ledge still in place, attach barrel bolts to all four corners of the top and then remove the ledge.

Step 13. Attach the Casters

Follow the manufacturer’s instructions to attach the casters to the bottom of the cart.

Step 14. Attach Your Machine

Follow the manufacturer’s instructions to attach your machine to the table top.

Step 15. Attach the Underside of the Table Top

Place the remaining piece of plywood on the underside of the table top and clamp. Drill countersink holes around the edge and attach using wood screws.

NOTE: Do not use glue in case you need to remove the plywood to access the interior of the table top.

Just checked out your Flip-Top Tool Stand along with a couple of other ones. I was wondering if your table tiop could support two pieces of equipment. I’m thinking along the lines of a thickness planer and an oscillating/belt/spindle sander. I like the fact that yours in pretty minimal in ways of material and using the KISS principal for assembly. Looking forward to hearing back from you.

Hi Randall – I only have one machine mounted on mine, but several readers have mounted tools on both sides (router table on one side, planer on the other, etc.)

Hi Scott! I am kind of a newbie to woodworking and I always seem to have trouble with lumber and squaring. I made the flip top table and everything was going great until it wasn’t. lol. The base is out of square and the top doesn’t flip. It’s off by about and inch and a half when I measure from corner to corner on the table uprights that hold the flip top. Is there anything I can do to salvage the piece without starting all over? I do get frustrated with the lumber at the big box stores. I take a lot of time to pick out pieces that look straight. I did use corner square clamps when I assembled it. Thanks so much. Mary

Hi Mary – I know how frustrating this can be. Unfortunately, I don’t know of way to fix something that isn’t square after it has been assembled. One thing I would mention is, if you consistently end up with joints that aren’t square, you might want to check the accuracy of your miter saw. If your miter saw is cutting square the joints are usually square too. There are also some helpful tips in this tutorial about getting accurate cuts.

Thanks Scott! A nice simple functional setup, just what I was Looking for.

I like the design and will make it but with the axes of the tilt going the other way across the width

I have a small shop also and no truck. My use of plywood is very limited so I love this design. Do you think it could be shorted up to be 30″ x 24″? I am planning on putting my miter saw on it. Thanks

Hi Steve – You should be able to adjust the plans to make it shorter.

While I did not use your plan for my build, mine is about 80% identical to yours, being based on 2×4 construction. To answer the durability and weight questions, mine has the same DeWalt Planer at 75ish pounds on one side, and a 1″belt/6″ disk sander and my scroll saw on the other. Total tool weight is approximately 125 pounds and it’s quite capable.

My only suggestion to anyone building something along this line is use locking swivel casters. You’ll be glad you did!

Thank you, Scott, for this awesome idea! I built it and although getting the pivot holes lined up perfectly so the top flipped as it should, it was an enjoyable time building it. And for your readers, I mounted the same DeWalt planer that you have, on one side, and a Porter Cable Miter Saw on the other. If I knew how to attach a picture to this comment, I would show you.