DIY Drill Press Stand

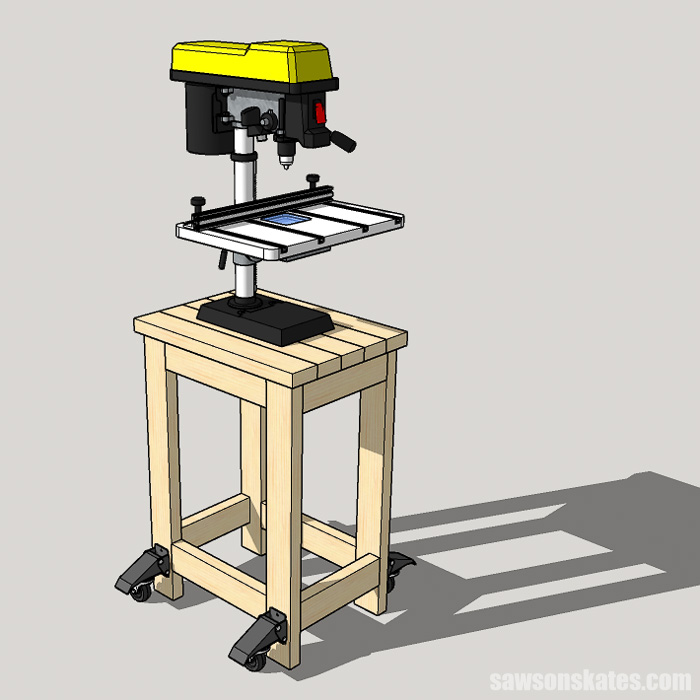

Make your drill press more functional with this simple and sturdy DIY drill press stand. It’s a quick afternoon project made with only five 2×4s.

DIY Drill Press Stand

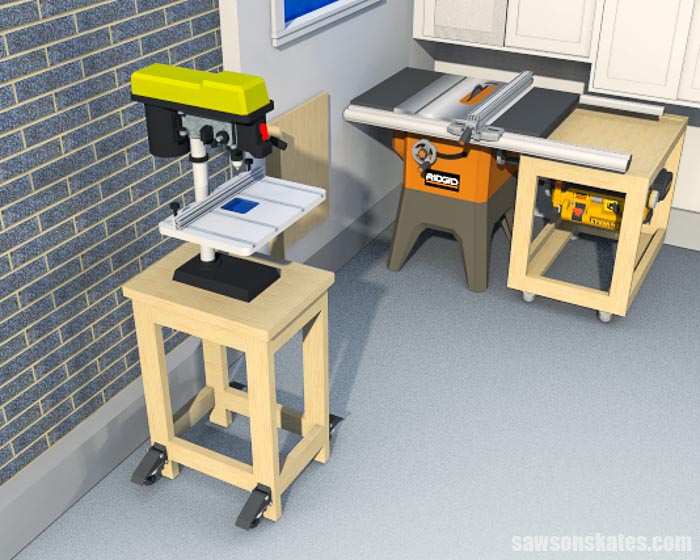

This simple and sturdy DIY drill press stand will make your drill press more functional and easier to use.

This beginner-friendly project is easy to make with five 2×4s, a few straight cuts, and a couple of common woodworking tools.

The compact size is perfect for a workshop, garage, or shed shop. Up top, there’s space for your benchtop drill press, and below there is space to add a shelf for more storage.

The free step-by-step plan includes all of the measurements, easy-to-follow instructions, and detailed diagrams. Get your free plan now and build one today.

You may also enjoy this DIY power tool stand and this DIY folding workbench.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Table of Contents

- Inspiration for This Project

- Where Can You Use This Drill Press Stand?

- What Tools Do You Need to Make a Drill Press Stand?

- What Wood Should You Use?

- Customize Your Drill Press Stand

- How Do You Finish the Drill Press Stand?

- How to Make a DIY Drill Press Stand

- Get the Free Printed Plan

Inspiration for This Project

I recently shared plans for this DIY power tool stand that I made for the local historical society where I volunteer. I received feedback from DIYers that they liked the simple construction and no-frills design. So I decided to add a smaller, DIY drill press stand to the collection.

I’ve been thinking about building a drill press stand, but the thing is, my drill press is a little unusual. It’s an early 1900s benchtop drill press that I inherited from my grandfather. This thing is huge! It’s cool and works well, but it’s nothing like what you can buy now.

I would need a big, bulky stand, which wouldn’t be a good fit for most DIYers. Instead, I wanted to design a project that you could use with a modern benchtop drill press. So I adjusted the power tool stand plan to make this project a little taller, the width a little narrower, and the length a little shorter.

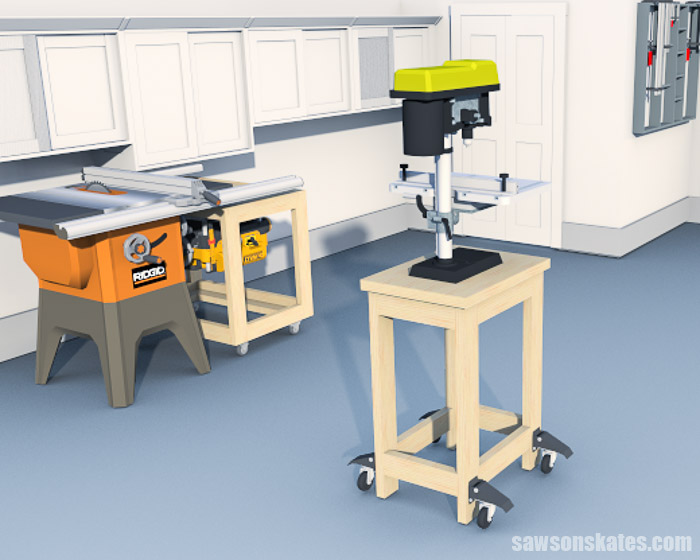

I didn’t actually build this project, but I still wanted to share it with you. So I decided to share what the finished project may look like using renderings, which is similar to how I shared my small workshop layout with you.

Here’s what I came up with: a small, sturdy, easy-to-make drill press stand.

Where Can You Use This Drill Press Stand?

This portable drill press stand would be perfect for a small shop, garage, or shed workshop.

Back to Table of ContentsWhat Tools Do You Need to Make a Drill Press Stand?

This drill press stand is a simple, beginner-friendly project that you can build in an afternoon using basic woodworking skills and just a few common woodworking tools.

Tools like a miter saw, pocket hole jig, and a drill.

Miter Saw

You can use a miter saw to cut all of the parts to length for this project.

Related: 7 Miter Saw Tricks Every DIYer Should Know

Pocket Hole Jig

You can use any pocket hole jig to drill the pocket holes for this project.

Related: Which Kreg Pocket Hole Jig Should You Buy?

Drill

You will need a drill to make the pocket holes and a Forstner bit to make holes for the table top fasteners. You will also use the drill to drive the pocket screws and wood screws that join the pieces together.

Related: Impact Driver vs Drill: What’s the Difference?

Back to Table of ContentsWhat Wood Should You Use?

I designed this project so that you could make it without plywood. That means you won’t need a circular saw or table saw to build this project. Instead, I designed this drill press stand so that you could make it with only five pine 2×4s.

Related: Beginner’s Guide to Wood Sizes

Customize Your Drill Press Stand Plans

There are several ways that you can customize your drill press stand. Customizations include adding a shelf, adding drawers, and adding wheels.

Shelf

This is a no-frills project, so I didn’t include a shelf at the base of the stand. You could easily add a bottom panel to the base of your project for additional storage.

Drawers

Again, this is a no-frills project, so I designed this stand without drawers. You could easily add drawer slides to the side pieces and build several drawer boxes to add additional storage to your project.

Related: How to Build DIY Drawers

Caster Wheels

I usually add wheels to make all of my workshop projects mobile, but you can build this project with or without wheels. This workbench caster kit would be an easy way to add wheels to make your project mobile.

How Do You Finish the Drill Press Stand?

You could finish this power tool stand in a variety of ways. It could be left natural, painted, etc.

I usually paint workshop projects to give them a finished, store-bought look.

Back to Table of ContentsHow to Make a DIY Drill Press Stand

Printed Plan

- Get the FREE plan here (includes detailed instructions, measurements, and bonus tips).

Supplies

- Wood (per printed plan)

- 2-½” Pocket Screws

- #6 1” Wood Screws

- #8 1-¼” Wood Screws

- Wood Glue

- Figure 8 Table Top Fasteners

Tools

- Tape Measure

- Drill

- Kreg Jig

- Kreg Multi-Mark

- Miter Saw

- Awl

- ⅝” Forstner Bit

- Chisel

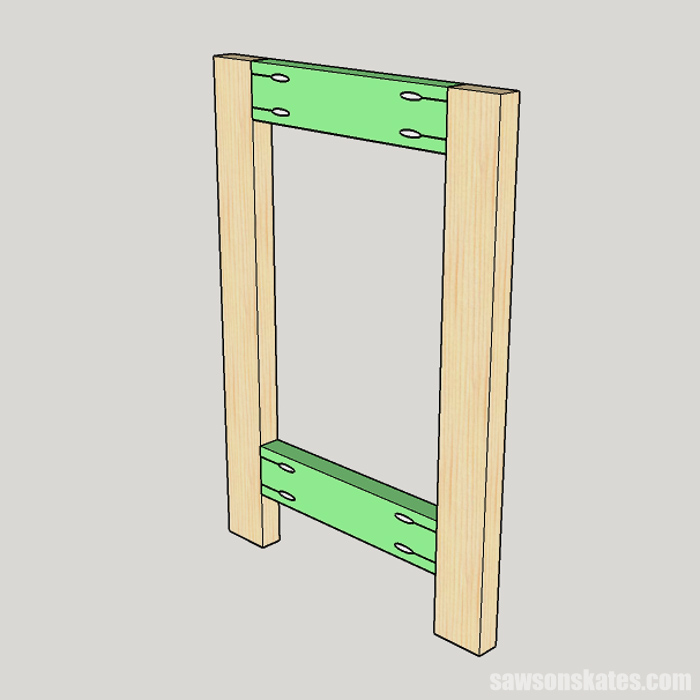

Step 1. Make the Leg Assemblies

Cut four pieces of wood to length for the legs. Cut four pieces of wood to length for the rails and drill pocket holes in each end.

Related: How to Use a Kreg Pocket Hole Jig

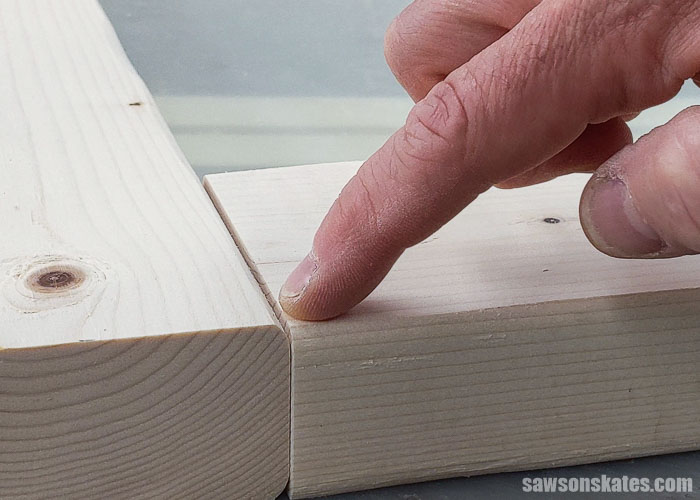

📝 NOTE: The edges of 2×4s are rounded. Cut edges butted up to rounded edges doesn’t look right to me.

This step isn’t necessary, but if you have a router, you may want to use a round-over bit on the cut edges so they will match the rounded edges of the 2×4s.

Related: How to Use a Router Table for Beginners

To help position the bottom rail, cut two pieces of scrap wood to length, and clamp the scrap wood to the bottom of each leg.

Apply glue to the ends of the rails and clamp. Attach using 2-½” pocket screws.

Repeat for the other leg assembly.

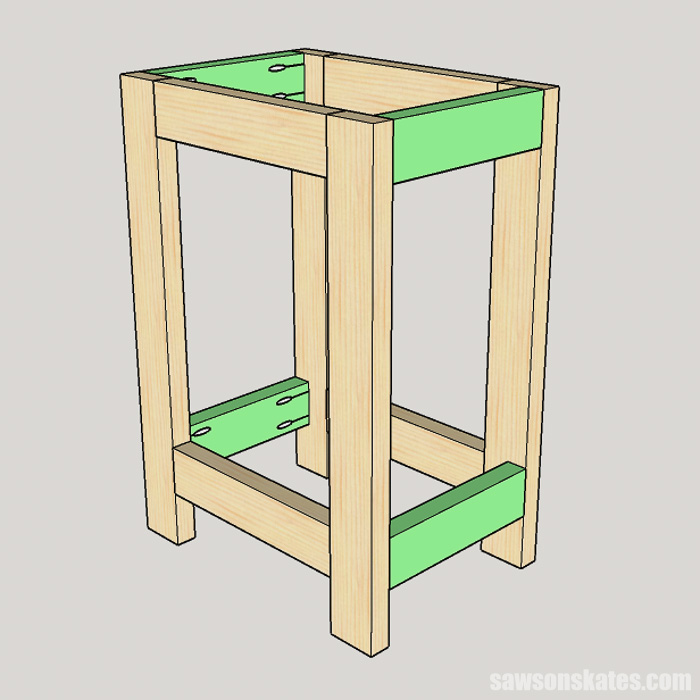

Step 2. Attach the Side Rails

Cut five pieces of wood to length for the rails and drill pocket holes in each end. Four of the pieces will be used as side rails, and one will be used as a stretcher in Step 3. The stretcher will help support the weight of the drill press.

💡 TIP: When I built this power tool stand, I attached all of the side rails to one leg assembly. Then I joined the first leg assembly (with the side rails) to the second leg assembly.

Again, to help position the bottom rail, use pieces of scrap wood cut to length. Clamp the scrap wood to the bottom of the leg. Apply glue to the end of the bottom rail and clamp. I used a speed square to help keep the rails square to the leg assembly. Attach using 2-½” pocket screws.

Apply glue to the top rail, position flush with the top of the leg assembly, and clamp. Attach using 2-½” pocket screws.

Repeat for the remaining rails.

Apply glue to the ends of the side rails, position the first leg assembly on the second leg assembly, and clamp. Attach using 2-½” pocket screws.

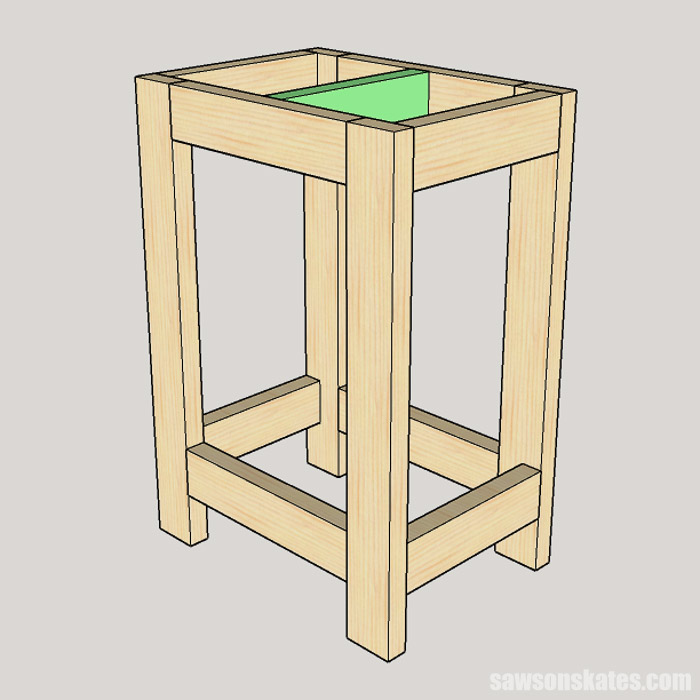

Step 3. Attach the Stretcher

Apply glue to the ends of the stretcher (from Step 2) center on the long rails and clamp. Attach using 2-½” pocket screws.

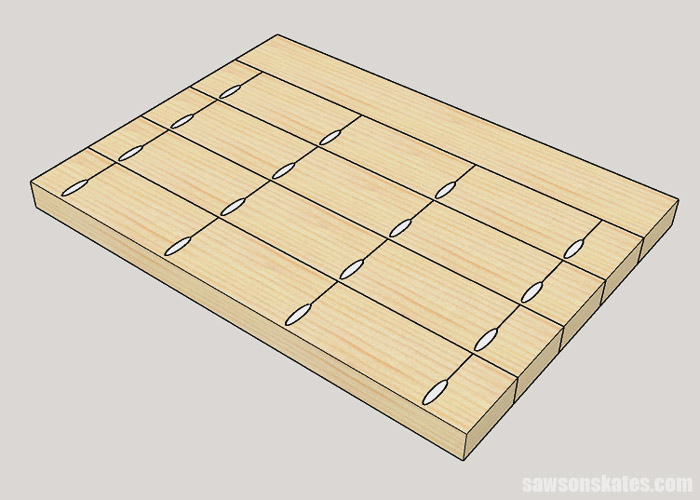

Step 4. Make the Top

Cut five pieces of wood to length for the top. You can assemble the top with glue or edge join the top with glue and pocket holes.

Related: How to Edge Join with Pocket Holes

I only used glue to assemble the top for the power tool stand, but I wanted to show how you can make the top with pocket hole joinery for this project.

Use the diagram to drill a pocket hole at each location. Apply glue to the edges and clamp. Attach using 2-½” pocket hole screws.

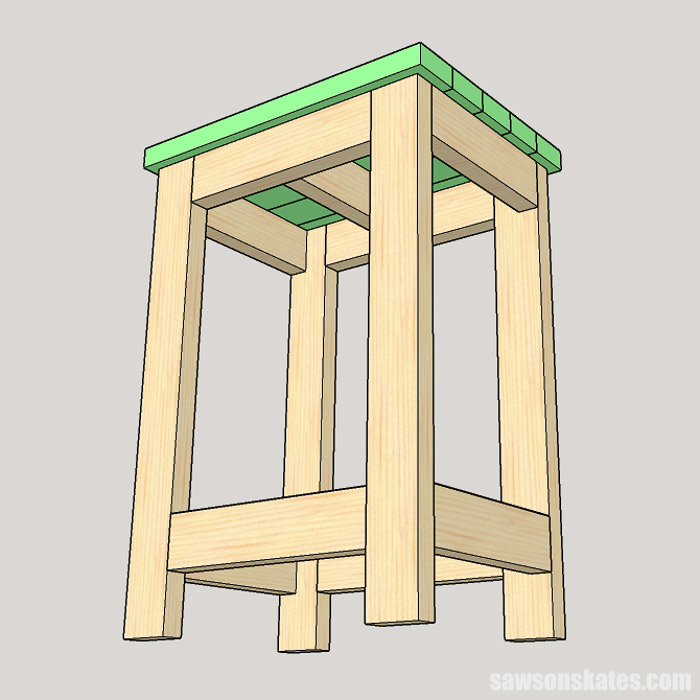

Step 5. Attach the Top

Use the diagram in the printed plan to lay out the locations for the table top fasteners. Table top fasteners allow the top to move with seasonal changes. Preventing movement caused by seasonal changes could cause the top to crack.

Related: How to Attach a Table Top (the Right Way)

Use an awl to make a starting point for the drill bit.

Related: What is an Awl? (+ How to Use It)

Use a Forstner bit to drill the holes for the fasteners. The holes need to be about an ⅛” deep. Use painter’s tape to make a depth stop on the drill bit.

Related: What is a Forstner Bit? (& How to Use It)

Use a chisel to square the corners of the hole.

Attach a table top fastener to each hole using a #6 1” wood screw.

Center the top on the legs. Attach using #8 1-¼” wood screws through the table top fasteners.

Step 6. Attach the Drill Press

Use the appropriate fasteners to attach your drill press to the table top.

Final Thoughts

This simple and sturdy DIY drill press stand will make your drill press more functional and easier to use. This beginner-friendly project is easy to make with five 2×4s, a few straight cuts, and a couple of common woodworking tools.

Get the free plan (including the detailed instructions and measurements) now!

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

Looks like a great plan for my belt sander also!

That’s a great idea, Ken!

Scott, your plans are so detailed yet very easy to follow, they are awesome for me, a retired auditor who is detailed oriented, can follow with ease. The images and verbiage is perfect.

Thank you for the compliments, Alan. I’m glad you’re enjoying the plans!

I have finally inherited a table top drill press that used as a little girl (I’m 71 now), at my Dad’s shipyard! The drill press stand is just what I need for my garage! Can’t wait to get it done!