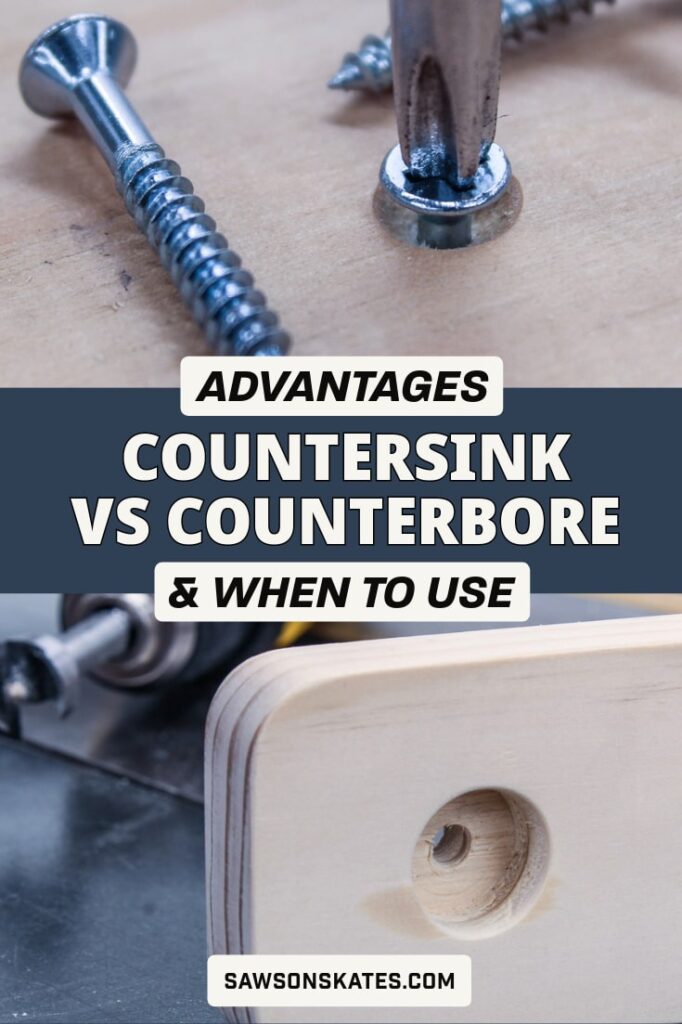

Countersink vs Counterbore (Advantages & When to Use)

Should you countersink or counterbore? In this side-by-side comparison, learn the differences and which to use for your woodworking project.

When it comes to woodworking, you may have heard the terms “countersink” and “counterbore,” but what’s the difference between them? In this article, I’ll break down the differences and advantages of each and help you decide which is best for your project.

Table of Contents

- What is a Countersink Hole?

- What is a Counterbore Hole?

- What is the Difference Between a Countersink and a Counterbore Hole?

- Should I Counterbore or Countersink?

- Counterboring vs Countersinking Comparison Chart

This article contains affiliate links. If you purchase from these links, I may earn a small commission at no additional cost to you. Visit my site policies for more information.

What is a Countersink Hole?

A countersink hole, also called countersinking, is a cone-shaped hole drilled into the surface of a material. It’s wider at the top than the bottom, and the tapered recess allows fasteners such as screws with an angled shape, known as a countersunk head, to sit flush with the material’s surface.

What is a Countersink Used For?

Woodworkers use countersink holes to recess screw heads to make them flush with the wood’s surface. Screws protruding from your project can cause it to look unfinished, while countersinking produces a smooth surface, creating a professional and polished result.

Countersinking is a versatile technique you can use nearly anytime you need to drive a screw. However, aesthetically speaking, I believe it’s most beneficial when the screws are visible on a finished surface, and you can’t hide them using another method, such as pocket hole joinery.

Related: How to Use a Pocket Hole Jig (& Beginner Pitfalls to Avoid)

For example, I countersunk screws on the exterior of this boot rack, bird feeder, and saw blade storage rack because I didn’t have an option for hiding them, and they were visible on the finished project.

You can also drill the countersink hole a little deeper, allowing the screw’s head to sit below the material’s surface and hide it with wood filler.

Related: Wood Putty vs Wood Filler (Which to Use & Why)

What are the Advantages of Countersinking?

Including aesthetics, countersinking also has several practical advantages.

Creates a Smooth Surface

As I mentioned, a countersink hole matches the screw’s angle, allowing it to sit flush with the material’s surface, creating a smooth, finished appearance.

Reduces Splitting Risk

When you drive a screw into wood, it creates an outward force that can cause the wood to split. Drilling a countersink hole first creates a recessed area for the screw’s head and makes a pilot hole, creating clearance for the screw’s threads, reducing the outward force and the risk of splitting the material.

Related: How to Drill Pilot Holes (Why, When & Correct Size)

Prevents Tear Out

Softwoods and hardwoods have different properties affecting how you can drive screws.

Softwoods, such as pine, are easier to drive screws flush without countersinking; however, the screw’s head crushes the wood fibers, causing the material to tear out, resulting in a jagged edge. Countersinking prevents tear-out by creating a tapered recess where the screw’s head can sit.

Hardwoods, such as oak and maple, are more difficult to drive screws flush without countersinking because they’re denser, making it difficult for the screw to go in and causing the screw’s head to stand proud of the surface.

Increases Joint Strength

The tapered shape of a countersink hole creates a larger surface for a screw’s head to contact the wood, allowing it to distribute the force over a wider area, resulting in a stronger joint.

How Do You Countersink Screws?

Countersinking screws is simple, but there are a few steps you should take to ensure success.

Gather Your Tools

You’ll need a drill, a countersink drill drill bit, and a driver bit.

Mark the Location

Use a pencil to mark the spot where you want the screw to go, and use an awl to make a starting point for the drill bit.

Adjust Your Drill’s Settings

Chuck the bit in your drill.

Drill the Countersink Hole

Slowly drill the countersink hole, keeping the bit perpendicular to the surface.

Drive the Screw

Screw the screw into the countersink hole until the head is flush with the surface.

Check out my step-by-step tutorial showing how to use a countersink bit.

What is a Counterbore Hole?

A counterbore hole, also known as counterboring, is a cylindrical, flat-bottomed hole drilled into the surface of a material. It’s used to recess the head of a screw or bolt so that it’s flush or sits below a material’s surface.

Counterbore holes are typically used with flat-bottomed fasteners such as bolts, hex-head screws, and other fasteners with a flat head.

A counterbore’s size is determined by the fastener you’ll be using. The diameter of the hole must be large enough to accommodate the head of your fastener, and the depth must be deep enough to allow it to sit flush or below your workpiece’s surface.

What is a Counterbore Used For?

Counterboring is used to recess a fastener’s head below a material’s surface and is most commonly done when it interferes with another object or structure and needs to be set below it.

For example, when I installed the door knob for this DIY trash bag dispenser, the screw protruded from the back of the door, preventing it from closing completely.

I solved this problem by using a Forstner bit to drill a counterbore hole slightly larger and deeper than the screw’s head, creating a shallow depression it could sit in.

Related: What is a Forstner Bit? (& How to Use It)

Thanks to the counterbore’s recessed area the screw sits below the door’s surface, allowing it to close properly.

Counterbores are also frequently used in construction projects, such as as attaching deck railings.

Here are some other cases where counterboring may be the best option:

- To create a smooth, finished look. A counterbore hole allows the fastener’s head to be flush or below the material’s surface, giving a more professional appearance.

- To prevent snagging. Fasteners set into counterbore holes are less likely to snag clothing or cause skin injuries.

- To provide a more secure footing for the fastener. Counterboring creates a larger surface area for the fastener to grip, providing a stronger connection.

- To allow the addition of washers. A washer helps to distribute the force of the fastener more evenly.

- To allow the screw to be covered with a decorative cap. This can be a great way to add a touch of style to your project.

What are the Advantages of Counterboring?

Counterboring offers many advantages. The main advantage is that it creates a larger surface area for the screw to grip, making it less likely to loosen over time and providing a more secure footing for the fastener. Additionally, counterboring allows the screw head to be hidden from view or covered with a decorative cap, giving your project a polished look

- Increased holding strength: The flat-bottomed recess provides a larger surface area for the screw or bolt to grip, making it more secure. This is especially important for applications where the fastener is subject to high loads.

- Improved appearance: A counterbored hole allows the screw or bolt head to sit flush with or below the material’s surface, improving the finished project’s overall appearance. This is often important in applications where aesthetics are a priority.

- Ability to use larger screws or bolts: A counterbored hole can accommodate larger screws or bolts than a standard drilled hole. This can be useful in applications where more holding strength is required.

How Do You Counterbore?

You can make counterbore holes in several ways, either in a single step using a dedicated bit or in two steps using a Forstner bit and a twist drill bit.

Since I don’t use counterbores frequently, I don’t own a tool for making them. But no worries, I’ll share the simple steps for getting the job done with a Forstner and twist bit.

1. Mark your hole location. Use a pencil to mark the center point of the counterbore hole on your workpiece, and use an awl to make a starting point for the drill bit.

2. Drill the counterbore. Select a Forstner bit with a diameter slightly larger than your fastener and washer if you are using one. Align the Forstner bit’s spur with the starting point, and begin drilling until you reach the desired depth.

3. Drill the pilot hole. Position a twist drill bit approximately the size of your fastener’s shank in the divot created by the Forstner bit, then drill until you reach the other side.

What is the Difference Between a Countersink and a Counterbore Hole?

Now that we have discussed countersink and counterbore holes let’s look at their differences. But first, let’s review what they have in common.

- They are both used to recess the heads of screws or bolts.

- They both improve your project’s aesthetics.

- They both help to prevent the screw or bolt from coming loose.

Shape and Size

The main difference between countersinking and counterboring is the shape of the hole they create. Countersink holes are tapered, while counterbore holes have a flat bottom.

The size of the hole matters, too. Countersinking is typically used for smaller screws to recess the screw head flush with the wood’s surface.

Counterboring is typically used for larger fasteners to recess their heads below the wood’s surface. Counterbore holes can also be used to accommodate washers.

Fastener Types

Countersink holes are typically used with wood screws, while counterbore holes are usually used with flat-headed fasteners such as bolts and socket head cap screws.

Tools Used

You can drill countersink holes with a regular drill bit or a dedicated countersink bit, while counterbore holes require a Forstner bit.

Applications

Countersink holes are when the screw head must be flush with, or slightly below, the workpiece’s surface. Counterbore holes are usually used to recess a fastener’s head when it would otherwise interfere with another object or structure and needs to be set below it.

They can also be used for aesthetics – allowing you to place a decorative cap over the screw head.

Should I Counterbore or Countersink?

The answer to whether you should counterbore or countersink depends on the type of fastener you’re using and the desired appearance.

- Countersinking creates a smaller, conical hole that fits a screw’s countersunk head, such as wood screws. Countersinking ensures that the screw head is flush with the material’s surface, giving a smooth finish.

- Counterboring creates a larger, cylindrical hole that fits a fastener’s head, such as a hex head screw or bolt. Counterboring allows the fastener head to sit below the material’s surface.

It all comes down to your fastener’s size and the desired look for your project. Choose countersinking when using a smaller wood screw and want the head to be flush with the workpiece’s surface. Choose counterboring when you need a bigger hole for a larger fastener or to recess the head below the surface.

Counterboring vs Countersinking Comparison Chart

| Countersink | Counterbore | |

|---|---|---|

| Hole Shape | Conical | Cylindrical |

| Fastener Type | Countersunk Head | Flat Head |

| Appearance | Flush with Surface | Below Surface |

| Use with Washer | No | Yes |

| Tool Required | Countersink Bit | Forstner Bit |

Final Thoughts

Countersinking and counterboring are two common techniques used in woodworking for creating recesses in wooden materials. Both provide a secure and visually appealing result, but the most suitable option will depend on the size and type of fastener you’re using.

Countersink holes are typically used for smaller screws, while counterbore holes are usually used with larger flat-headed fasteners such as bolts and socket head cap screws.

Interested in woodworking but need help figuring out where to start? Join the FREE Saws on Skates® Beginner Woodworking VIP list and gain instant access to top-notch tool comparisons, tool tutorials, and free woodworking plans. Join for FREE now!