How to Make a French Cleat

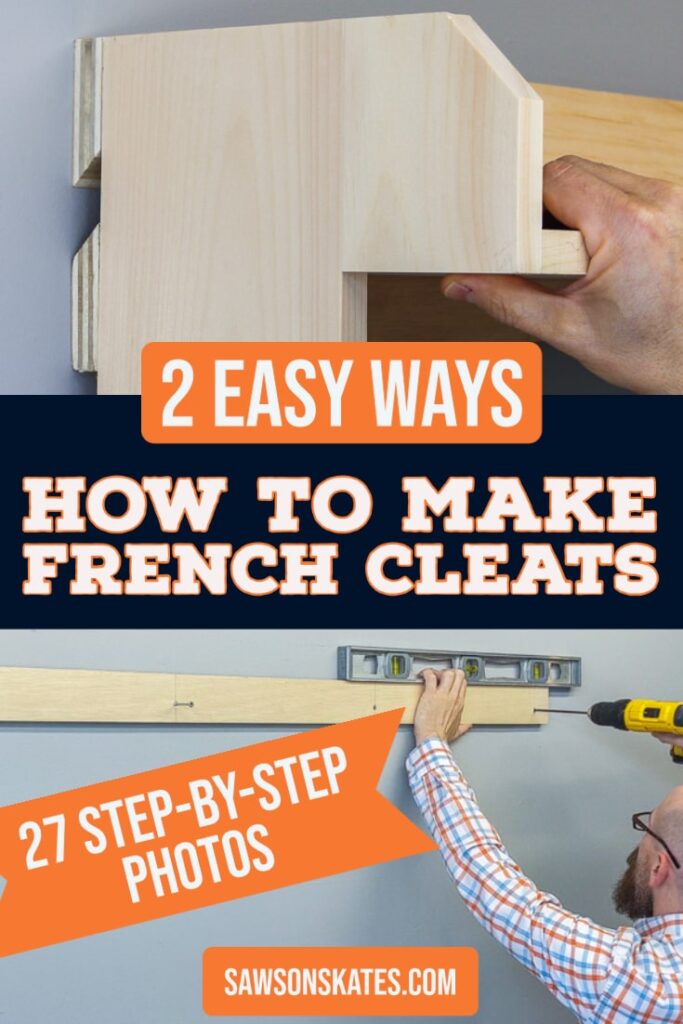

A french cleat is a simple, strong way to hang heavy items on the wall. Learn what wood to use, what angle to cut, and two easy ways to make french cleats.

How to Make a French Cleat

A french cleat is a strong, simple way to hang heavy items like cabinets, artwork, tools, and more.

In this tutorial, you’ll learn what type of wood to use, what angle to cut, and how to install french cleats. Plus, I’ll share step-by-step how to make a french cleat with a table saw, and a circular saw.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Table of Contents

- What is a French Cleat?

- Where Can You Use a French Cleat?

- What Type of Wood Should You Use?

- What is the Best Size Wood to Make a French Cleat?

- What Angle Should You Use to Make a French Cleat?

- Can You Hide French Cleats?

- What Kind of Saw Can You Use?

- How to Make a French Cleat

- How Do I Prefer to Make French Cleats?

- Can You Buy French Cleats?

- How to Install a French Cleat

- Video: How to Make and Install French Cleats

What is a French Cleat?

A french cleat is a strong, simple way to hang heavy items on the wall. It’s made from two pieces of wood. Each piece has a rip cut on one edge. The rip cut is beveled to 45 degrees.

Related: Beginner’s Guide to Woodworking Terms

One cleat is attached to the back of the item you want to hang. The cleat is attached with the bevel facing down and towards the wall.

The other cleat is attached to the studs in the wall, with the bevel facing up and away from the wall.

Then, the cleat on the back of the item hooks onto the cleat attached to the wall. The two boards interlock and gravity holds the cleats together.

Fasteners are not needed to join the cleats together. Because fasteners are not required, you can separate the cleats, and the item can easily be removed and reconfigured. French cleats are a popular way to store tools in a workshop because of the ability to remove and reconfigure them.

Related: 9 Clever Ways to Make a Small Workshop Feel Bigger

Where Can You Use a French Cleat?

- Cabinets

- Mirrors

- Artwork

- Fireplace mantles

- Headboards

- Shelving units

- Tool storage for workshop or garage

What Type of Wood Should You Use?

French cleats are pretty forgiving. Cleats can be made with just about any type of wood. You could use solid wood like 1×4s and 1×6s. Or you could use ½” or ¾” plywood that has been ripped into strips.

Related: Beginner’s Guide to Wood Sizes

That said, French cleats are often made from plywood. When making french cleats look for a quality plywood that is relatively free of voids and knots.

Back to Table of ContentsWhat is the Best Size Wood to Make a French Cleat?

As I mentioned earlier, french cleats are forgiving, but there are some general recommendations regarding the size of the cleats.

Thickness

- ¾” wood is typically used for heavy objects

- ½” wood is typically used for lighter things like mirrors and artwork

Width

- Usually made from a board that is 5” wide, but you can make them wider or narrower

What Angle Should You Use to Make a French Cleat?

French cleats are usually cut at a 45-degree angle. But the angle doesn’t have to be exactly 45 degrees. Let’s say you wanted to hang a single mirror on the wall. If you cut a french cleat from a single board at 47 degrees, the two sections of the cleat would fit together.

But you may want the angle to be exact for some projects. Let’s say you wanted to make a batch of french cleats for a tool storage wall. You’ll likely want the angle to be the same for each cleat. Making the angle the same for each cleat will ensure that the objects can be removed and reconfigured, and all of the cleats will fit together correctly.

Back to Table of ContentsCan You Hide French Cleats?

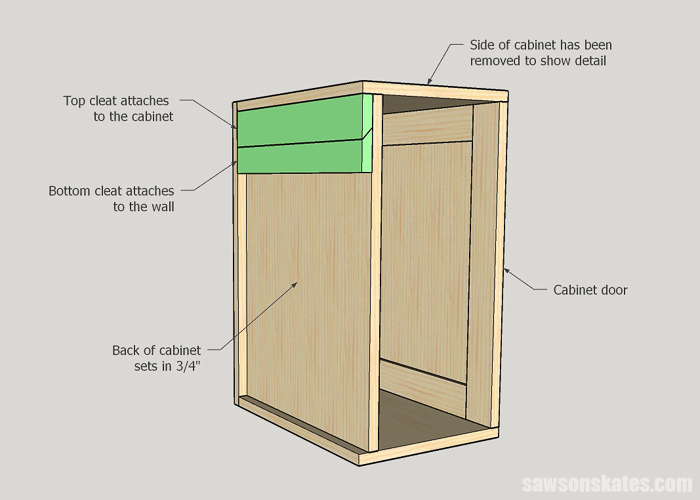

French cleats are often exposed at the back of the object. The cleats are functional but not necessarily attractive. By planning ahead, you can hide the cleat within your project.

Let’s say you want to build a cabinet and attach it to the wall with a french cleat. Instead of making the back of the cabinet flush with the sides, you could set the back in ¾”. Setting the back in ¾” would allow space for a ¾” cleat. The sides of the cabinet would conceal the cleat. Hiding the cleat within the cabinet would give your project a more polished look.

What Kind of Saw Can You Use?

You can use a table saw, or circular saw to make french cleats.

It’s important to make sure the cut is straight. If the cut is not straight, the cleats may not fully contact each other. The result is a french cleat that may not be as strong as it could be.

Also, if the cut is not straight, the object you’re trying to hang might not be level.

Table Saw

Here are some tips and tricks for using a table saw for making french cleats:

- Parallel the Rip Fence:

A misaligned rip fence can affect the quality of your cuts and can increase the chances of kickback. Kickback happens when a piece of wood binds against the blade or drifts away from the rip fence towards the blade and is propelled back at a high rate of speed. Kickback is dangerous. Learn an easy way to parallel a rip fence in here. - Clean the Blade:

Wood pitch can build up on saw blades. This buildup can increase the chances of burning the edges of your workpiece. The buildup can also require more feed pressure. In other words, the buildup can make a sharp blade feel like a dull blade. Learn how to clean saw blades and which cleaner I use here. - Wax the Table Saw:

Wood pitch not only builds up on your saw blades but also on the table and rip fence of your table saw. This buildup causes friction. Waxing your table saw reduces friction and reduces the chances of oxidation. Learn how to wax your table saw and which wax I use here. - Set the Blade Angle:

Sometimes, precisely setting the blade angle can be difficult. Using a digital angle gauge is a quick and easy way to precisely set the angle of your table saw every time. Learn how to use a digital angle gauge here. - Set the Blade Height:

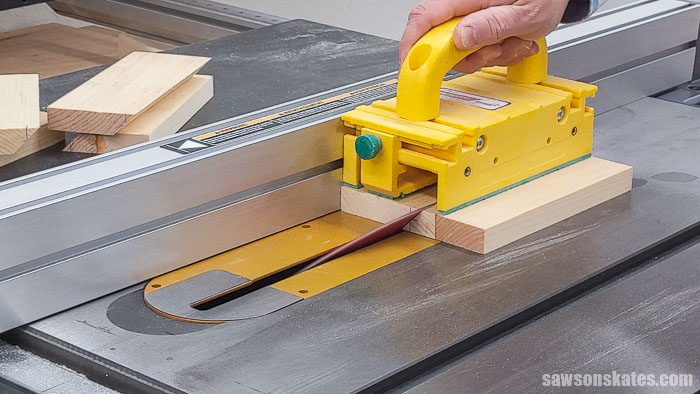

Setting the blade 2″ to 3″ above the workpiece produces the least friction and the least amount of heat. But it also creates a greater chance for injury because more of the blade is exposed. I set my blade about an ⅛” above the material. Setting the blade an ⅛” above the material helps to reduce injuries because a smaller amount of the blade is exposed. - Use a Push Block:

Long push sticks provide less control over a workpiece and creates a pivot point. Creating a pivot point could allow your hand to fall into the blade. Instead of a push stick, I use a push block like this one. It has a lower center of gravity, so it doesn’t create a pivot point like a push stick. - Make a Test Piece:

Use a piece of scrap wood to run a test piece to make sure everything is adjusted the way you want before making any cuts on the pieces for your project.

Circular Saw

Just like a table saw, a circular saw can benefit from a clean saw blade. Waxing the baseplate of the circular saw will help reduce friction.

Related: How to Change a Circular Saw Blade

A circular saw is a handy tool, but it doesn’t usually cut straight without a bit of help from a fence or a guide. This means you’ll need a guide to cut a french cleat.

I used the Kreg Straight Edge Guide to make the french cleats for this tutorial. I have to give credit where credit is due. In my review of the Straight Edge Guide, I said that I would use it again, but “there are a few tools that I might reach for first before using my Straight Edge Guide.”

But I have to say the Straight Edge Guide was a quick and easy way to make french cleats.

Related: How to Use a Kreg Straight Edge Guide

Back to Table of ContentsHow to Make a French Cleat with a Table Saw

Printed Instructions

- Get a FREE copy of the French Cleat Handbook including measurements and step-by-step instructions.

Supplies

- Wood (You could use 1×4s, 1×6s, or plywood. I used ¾” plywood for my cleats.)

- Tape Measure

- Kreg Multi-Mark

- Speed Square

- Digital Angle Gauge

- Table Saw

- Push Block (I used this one)

Tools

📝 NOTE: I’m showing just one way to use a table saw to make a french cleat. In this tutorial, I’m using ¾” plywood. You could use 1× material like a 1×4 or 1×6 instead. I’m making the two sections of the french cleat from one piece of plywood. You could also rip a 45-degree bevel on the edge of two pieces instead.

Step 1. Rip Plywood to Width

To get started, I ripped a piece of ¾” plywood to 5”.

📝 NOTE: Some safety equipment has been removed to show detail. Follow all instructions for your saw.

Step 2. Mark the Angle

First, I located the center on the width of the board.

Next, I located the center on the height of the board.

Then, I used a speed square to mark the intersection of those two points.

Step 3. Cut the Bevel

I used a digital angle gauge to set the blade to 45 degrees.

Related: How to Use a Digital Angle Gauge

Before I made any cuts on the pieces for my project, I tried the setup on a few test pieces. With the saw turned off, I positioned the 45-degree mark on the workpiece so that it was centered from side to side on the saw blade.

Then, I used a push block to make the test cut.

📝 NOTE: Some safety equipment has been removed to show detail. Follow all instructions for your saw.

I used my finger to feel both edges of the test piece and adjusted the fence until the pieces were the same width.

📝 NOTE: If you’re making cleats for a single object, the pieces don’t have to be the same width. But you may want the cleats to be the same for some projects. Let’s say you wanted to make a batch of french cleats for a tool storage wall. You’ll likely want the cleats to be the same width. Making the cleats the same will ensure that the objects can be removed, and reconfigured and all of the cleats will fit together correctly.

When I was happy with the setup on my test pieces, I made the cut on the plywood for my project.

📝 NOTE: Some safety equipment has been removed to show detail. Follow all instructions for your saw.

How to Make a French Cleat with a Circular Saw

Printed Instructions

- Get a FREE copy of the French Cleat Handbook including measurements and step-by-step instructions.

Supplies

- Wood (You could use 1×4s, 1×6s, or plywood. I used ¾” plywood for my cleats.)

- Rigid Foam Insulation

- Tape Measure

- Kreg Multi-Mark

- Circular Saw

- Kreg Straight Edge Guide

Tools

📝 NOTE: I’m using the Straight Edge Guide opposite of the Kreg instruction manual. Typically you would position the Straight Edge Guide on the good side (the side you want to keep) and cut on the waste side. In this tutorial, I’m positioning the guide on the waste side and cutting on the good side (the side I want to keep).

Step 1. Make the First Cleat

I used a Kreg Multi-Mark to measure in 2″ on each end of the board.

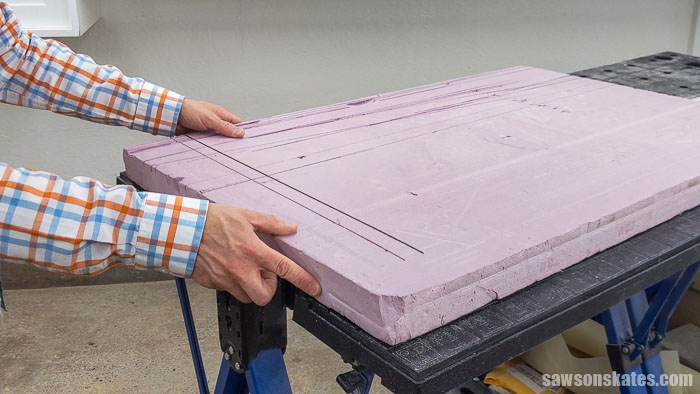

Next, I placed a piece of rigid foam insulation on my workbench. The insulation will protect my workbench when making the cuts.

Then, I placed the Kreg Straight Edge Guide on my workpiece. I positioned the cut line indicators on my marks, clamped the guide, and pushed the cut line indicators towards the guide.

Related: How to Use a Kreg Straight Edge Guide

I set my circular saw blade to 45 degrees.

Next, I made the cut making sure to keep the baseplate of the saw against the guide for the entire length of the cut.

Step 2. Make the Second Cleat

I used a Kreg Multi-Mark to measure in 2-¾” on each end of the board.

Next, I placed the Kreg Straight Edge Guide on my workpiece. I positioned the cut line indicators on my marks, clamped the guide, and pushed the cut line indicators towards the guide.

I set my circular saw blade back to 90 degrees.

Then, I made the cut making sure to keep the baseplate of the saw against the guide for the entire length of the cut.

How Do I Prefer to Make French Cleats?

I’ve always made french cleats using my table saw. This was my first time making cleats with a circular saw and the Straight Edge Guide.

As I mentioned earlier, I have to give credit where credit is due. In my review of the Straight Edge Guide, I said that I would use it again, but “there are a few tools that I might reach for first before using my Straight Edge Guide.”

But I’ve had a change of heart. The Straight Edge Guide was a quick and easy way to make french cleats. The next time I need to make some cleats, I will be using a circular saw, and my Straight Edge Guide instead of my table saw.

Back to Table of ContentsCan You Buy French Cleats?

Store-bought french cleat-style hangers are available if you don’t have the tools or time to make your own. Below are some options that you buy and have shipped to your home. I’ve used these for several projects, and they work well.

Back to Table of ContentsHow to Install a French Cleat

Printed Instructions

- Get a FREE copy of the French Cleat Handbook including measurements and step-by-step instructions.

Supplies

- 1-¼” Wood Screws

- 2-½” Wood Screws

- Tape Measure

- Kreg Multi-Mark

- Drill

- Countersink Drill Bit

- Level

- Stud Finder

Tools

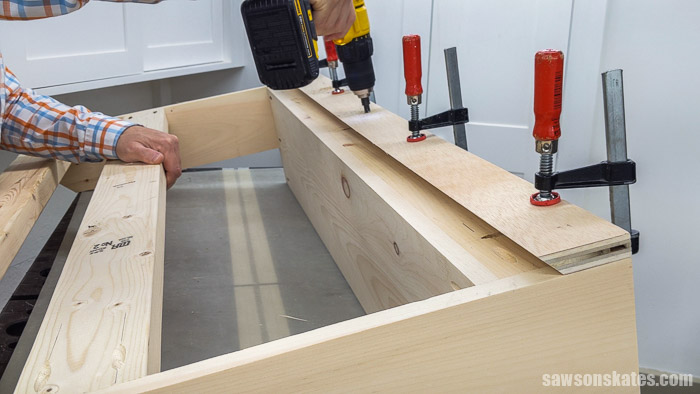

Step 1. Attach the Cleat to the Object

On the wide side of the cleat, layout the locations for countersink holes. The shorter side of the cleat will face the object. The countersink holes will attach the cleat to the object that you want to hang on the wall. For my project, I was mounting this yard tool rack on the wall in my garage.

Related: How to Make a DIY Yard Tool Rack

I used an awl to make a starting point for the drill bit.

Related: What is an Awl? (and How to Use it)

I used a countersink bit to drill a hole at each mark.

Related: How to Use a Countersink Bit

I attached the cleat using 1-¼” wood screws.

📝 NOTE: You may need to use a different length screw for your project.

I attached a piece of wood the same thickness as the cleat on the bottom of the rack. This piece makes the rack stand straight up and down on the wall.

Step 2. Attach the Cleat to the Wall

First, I positioned the rack where I wanted it on the wall. I used a pencil to mark the top edge and each side.

Next, I placed the second cleat on the back of the rack and measured to the bottom of the cleat. Mine measured 4-¾”.

📝 NOTE: Your measurement may be different.

At the wall, I measured down 4-¾” from the pencil line and made a mark.

Related: How to Use a Tape Measure Correctly (Tips for Success)

Then, I placed the bottom of the cleat on that mark. Be sure the short side is facing the wall, and the bevel is facing up. I leveled the cleat and used a pencil to draw a line the entire length of the cleat.

I used a stud finder to locate the studs along that line. After I found all of the studs, I used a pencil to mark the center of each stud on the wall.

Next, I placed the cleat back on the line and transferred the center of the studs from the wall onto the cleat.

I marked locations for countersink holes that will attach the cleat to each stud.

Next, I used an awl to make a starting point for the drill bit.

Then, I used a countersink bit to drill a hole at each mark.

At the wall, I placed the cleat back on the line with a level on top of the cleat. I attached the cleat using 2-½” wood screws.

Then, I hooked the cleat on the back of the rack onto the cleat on the wall.

Video: How to Make and Install French Cleats

Final Thoughts

A french cleat is a strong, simple way to hang heavy items like cabinets, artwork, tools, and more. They are easy to make with a table saw or circular saw.

Get the free french cleat handbook (including the detailed instructions and measurements) now!

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

Hi All,

Here in the uk we’ve been using French cleats for years in my case some 65years since my dad taught me.

We use it in both upper and lower cabinets in kitchen installation and bed room,bathrooms as well.

All our shop and garage storage is the same they’re so easy to produce and install.

However the best use is according to the boss ( my wife) after I showed her how to make them is for her bird boxes, bat rests and planters.

When the birds have finished raising their young off they pop then she starts sterilising them and replaced them after repairs as needed.

As for her planters they are hung on any available vertical structure, wall, fence, post ect where ever she sees fit and the removal is so easy lift straight up and pull away.

So dont be afraid of using this system it’s easy and providing you put the receiving pieces up level you’ll have no problems at all.

Enjoy

Ian and Margaret