Table Saw vs Circular Saw (Which Should You Buy?)

Can’t decide between a table saw or a circular saw? This in-depth comparison breaks down the differences, uses, and why you may want one instead of the other.

Table saws and circular saws both have their own unique benefits and drawbacks, which is why it can be difficult to decide which saw is right for your project. In this article, we’ll compare and contrast the differences between them and help you decide which saw is best for your needs.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Table of Contents

- What is a Table Saw?

- What is a Table Saw Used For?

- Table Saw Cutting Capacity

- What are the Pros and Cons of a Table Saw?

- What is a Circular Saw?

- What is a Circular Saw Used For?

- Types of Circular Saws

- What are the Pros and Cons of a Circular Saw?

- What are the Differences Between a Table Saw and a Circular Saw?

- Which is the Right Saw for You?

- Frequently Asked Questions

What is a Table Saw?

A table saw is a machine used to cut wood. It has a saw blade mounted underneath a tabletop that protrudes through a slot called the throat plate. The cutting depth can be adjusted by raising or lowering the blade and it may also be tilted to change the cut’s angle.

Related: Best Way to Set Table Saw Angle

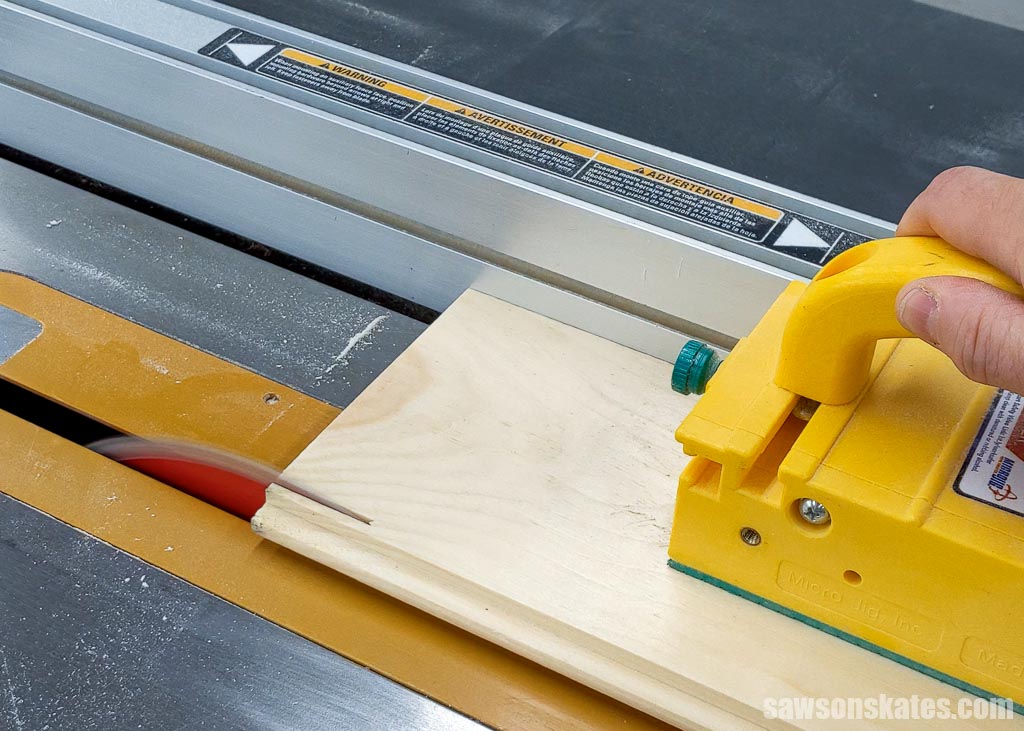

Table saws are often used with a rip fence, which guides the material while it’s being cut. To make a cut, the operator stands in front and pushes the workpiece towards the blade. A table saw’s sizable work surface allows it to handle large materials such as plywood sheets.

Because many table saws are heavy and bulky, transporting them may be difficult. They’re generally mounted on a stand with wheels, making them easier to move.

Related: 7 DIY Table Saw Stations for a Small Workshop

Table saws can be very dangerous if they’re not used properly. Every year, there are thousands of table saw-related injuries, and many of them are serious.

The most common type of injury is kickback, which occurs when the spinning blade forces the workpiece back towards the operator. Another danger is getting your fingers caught in the blade.

To avoid these dangers, it’s important to read your owner’s manual and always follow proper safety procedures when using a table saw.

Related: Beginner’s Guide to Table Saw Safety

What is a Table Saw Used For?

A table saw is a multipurpose tool that may be used to make various cuts, such as crosscuts; however, it’s not the most accurate tool for making these kinds of cuts. The main advantage between a table saw, and other saws is its ability to make precise rip cuts.

Rip Cut

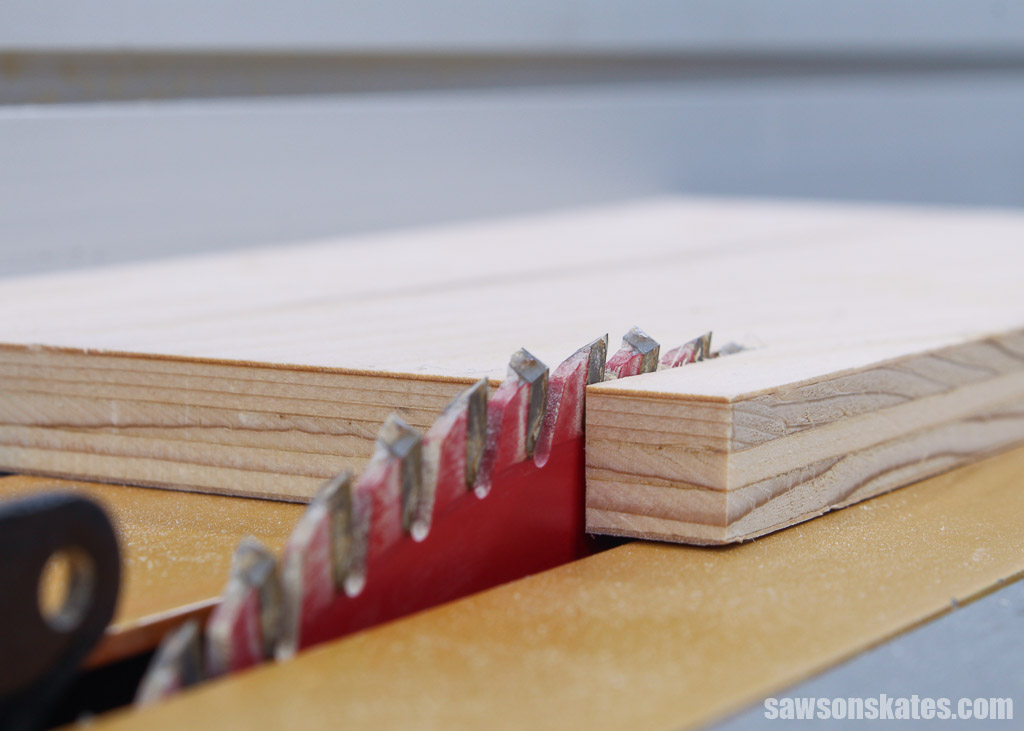

A rip cut is made along the length of a workpiece with the blade set at 90 degrees. It’s frequently used to reduce a board’s width or to cut plywood sheets to their required size for building DIY furniture or cabinets.

Related: How to Make DIY Cabinet Doors

Bevel Cut

A bevel cut is made along the length of a workpiece with the blade set at an angle other than 90 degrees.

Crosscut

A crosscut is made across the grain of a workpiece with the blade set at 90 degrees and used to cut boards to their desired length.

Crosscuts can be made with a table saw using either a miter gauge or a table saw sled.

A miter gauge is an accessory consisting of a handle, a small fence, and a metal bar that fits in the miter gauge slot in the saw’s table top. The workpiece is positioned against the gauge, which guides the workpiece as it’s being cut.

A table saw sled is a jig that’s used to make crosscuts. It consists of a base with runners that fit in the miter gauge slots and an attached fence. The workpiece is positioned against the fence, which guides it as it’s being cut.

Table saw sleds are more accurate than miter gauges because they provide more support for the workpiece.

Miter Cut

A miter cut is made across the grain of a workpiece with the blade set at an angle other than 90 degrees. It’s used to make cuts for molding, trim, and picture frames. Miter cuts can be made with a table saw using either a miter gauge or table saw sled.

Dados, Grooves, and Rabbets

Table saws may be outfitted with a dado blade which usually consists of a set of stacked blades that produce a wider blade. Dado blades are used to cut dados, grooves, and rabbets which create an area to join two pieces of wood.

- A dado is a cut made across the grain (across the width) of a workpiece.

- A groove is a cut made with the grain (along the length) of a workpiece.

- A rabbet is a cut made along the edge of a workpiece.

Table Saw Cutting Capacity

Rip Capacity

The maximum width that may be cut in one pass with a table saw is called the rip capacity. Many table saws have a ripping capacity of around 24 inches, meaning the maximum width you can cut in one pass is 24 inches.

Depth of Cut

The maximum thickness that can be cut in one pass with a table saw is known as the depth of cut. The cutting depth is the distance from the table top to the top of the blade. Many table saws have a cutting depth of around 3 to 4 inches, which means the maximum thickness that can be cut in a single pass is 3 to 4 inches.

What are the Pros and Cons of a Table Saw?

Pros

- Excels at making long, straight, precise rip cuts

- Has the ability to make crosscuts, dados, grooves, and rabbets

- Large surface can handle big pieces of wood such as plywood

Cons

- Many table saws are heavy and bulky, making them difficult to transport

- Can’t make all cuts as precisely as other saws

What is a Circular Saw?

A circular saw, sometimes called a Skilsaw, is a portable power tool with a blade mounted above a base plate. The blade may be raised or lowered through a slot in the plate, which allows you to control the cutting depth. The blade may also be tilted to change the angle of the cut.

To use a circular saw, you’ll place the plate on top of the workpiece and stand behind the tool. Then you’ll push the saw across the material, guiding the blade along the line you wish to cut.

Circular saws are dangerous for several reasons. First, because the blade is exposed and cuts beneath the workpiece, you can’t always see what is in its path, and it can easily cut through your fingers if you’re not careful. Second, the blade can bind in the material, causing the saw to kick back, which can also cause serious injury.

For these reasons, it’s important to be careful when using a circular saw. Make sure you follow the manufacturer’s safety instructions, you’re using the proper blade for the material you’re cutting, and be very mindful of where your fingers are in relation to the blade.

The portability of a circular saw is its greatest advantage. Circular saws are small and lightweight, making them easy to transport from one job site to another. Additionally, a circular saw’s small size is perfect for making cuts in tight spaces or hard-to-reach places, where another saw would be difficult to maneuver.

What is a Circular Saw Used For?

A circular saw may be used to cut a variety of materials such as lumber, plywood, MDF, and even concrete and metal.

I recently used my circular saw to cut some concrete blocks for a wall I was repairing. I used a masonry blade designed for cutting concrete, and it sliced through those blocks like a hot knife through butter!

Types of Cuts

Circular saws can perform the same tasks as table saws, such as making rip cuts, crosscuts, miters, and bevels.

Additionally, circular saws may be used for making compound cuts which combine two angles, a miter and bevel cut. This can be done by tilting the blade to one side while making a miter cut.

A circular saw can also make long and steep angled cuts, such as roof rafters that would be difficult to cut with any other saw.

A unique feature of a circular saw is its ability to make plunge cuts. A plunge cut is where you start the saw above the workpiece and then pivot the spinning blade into the material. This can be useful for cutting holes in the middle of material such as plywood.

One of the drawbacks of a circular saw is that it does not cut as precisely as a table saw since it lacks a fence to guide it in a straight line. To improve the accuracy, you may use various straightedges, and you may even use a circular saw freehand.

The advantage of using a circular saw freehand is that you can make cuts almost anywhere, but they are not as accurate as those made with a straightedge.

Freehand

To make a freehand cut, you first draw a cut line on the workpiece. Then, place the plate on top of the material and align the blade with the mark. Next, you must guide the saw along the cut line using hand-eye coordination.

Making freehand cuts can be difficult for beginners because it’s easy to lose control of the saw and have it veer off course. However, with practice, the cuts will get better, but they will never be as accurate as those made with a straightedge.

Straightedge

Using a circular saw with a straightedge is considerably easier and more accurate than making freehand cuts. A straightedge, depending on the situation, can be anything from a speed square to a circular saw guide or even a level or long board.

Related: How to Make a DIY Circular Saw Crosscut Jig

When working with a straightedge, such as a speed square, the square serves as a fence for the saw’s base plate. The plate is placed against the square, which guides the blade in a straight line.

You may also use accessories to make straight cuts with a circular saw, such as the Kreg Straight Edge Guide, Kreg Accu Cut, Kreg Rip Cut, or the Kreg Crosscut Station.

Related: 4 Ways to Make Straight Cuts with a Circular Saw

Types of Circular Saws

Standard

The most popular circular saw is the standard or sidewinder, which has a blade mounted on the side of the motor and blades ranging in diameter from 6-½ inches to 7-¼ inches.

The versatility of a standard circular saw makes it an excellent choice for cutting a range of materials, including plywood, construction lumber, and more. They’re also reasonably priced, making them ideal for beginners and those on a tight budget.

Related: 9 Woodworking Tools for Beginners

Worm Drive

A worm drive circular saw’s motor is positioned at a right angle to the blade. This arrangement makes the saw more powerful than a standard saw but also makes it larger and heavier. Plus, worm drive saws are generally more expensive than standard saws.

A worm drive saw might be your best option if you’re a professional carpenter or a DIYer who does lots of heavy-duty cutting.

Compact or Miniature

A compact or miniature circular saw is a smaller and lighter version of a standard saw with blades ranging in diameter from 3-¼ to 4-¼ inches.

It’s ideal for cutting in tight spaces, working with small pieces of lumber, or making cuts that require more finesse than a full-size saw can provide. However, it has a smaller cutting capacity and is not powerful enough for some jobs, such as cutting through thicker lumber.

Track Saw

A track saw has a circular saw mounted on a rail or track, which serves as a guide for making straight cuts. Track saws are excellent for making long, rip cuts and crosscuts in plywood and other sheet goods.

A track saw is a great option for carpenters or woodworkers who frequently build with sheet goods or who are looking for an alternative to a table saw.

Choosing the Right Circular Saw

Now that you know the basics about circular saws, it’s time to choose the right one for your needs.

If you’re a beginner or working on a tight budget, then a standard circular saw is a good choice. If many of your jobs involve heavy-duty cutting, you might want to consider a worm drive saw. If you need a more compact saw for working in tight spaces or making precision cuts, then a compact saw might be the best option. And if you frequently need to cut long, straight lines in sheet goods, you might want to consider a track saw.

Whichever type you choose, there are several things to consider when purchasing a circular saw. For example, you’ll want to think about the blade size and whether you’ll need a corded or cordless model.

Blade Size

The size of your circular saw’s blade will determine the maximum cutting depth for your saw. The cutting depth is the distance between the tip of the blade and the bottom of the plate and determines how deep a cut you can make. The bigger the blade, the more deeply it can cut.

The blade size you’ll need depends on the thickness and type of material you’ll be cutting. A circular saw with a 6-½ to 7-¼-inch blade will be more than enough for most basic cutting tasks. Smaller blades, on the other hand, can cut thinner materials but lacks the capacity to cut through thicker materials.

Related: How to Change a Circular Saw Blade (+ Blade Direction)

Corded or Cordless

Circular saws are available in both corded and cordless versions. Corded circular saws offer more power but require an electrical outlet, while cordless saws are more convenient but have less power.

If you’re going to be using your circular saw for heavy-duty tasks or making long cuts, then you’ll want to consider a corded saw. If you’re only going to be using it for occasional jobs or making shorter cuts, then a cordless saw might be sufficient.

What are the Pros and Cons of a Circular Saw?

Pros

- Lightweight, compact and portable

- Versatile tool that can make a variety of cuts

- Great for breaking down plywood and other sheet goods

- Relatively affordable

Cons

- Requires practice and skill to cut freehand

- Requires a straightedge to cut more accurately

- Can be dangerous

What’s the Difference Between a Table Saw and a Circular Saw?

Now that we have covered the basics of table saws and circular saws, it’s time to compare and contrast them.

Portability

One of the most significant differences between table saws and circular saws is portability. Table saws are much larger and heavier than circular saws, making them difficult to transport. On the other hand, circular saws are much more compact and lightweight, making them easy to carry with you wherever you go.

For example, I use a table saw in my workshop to cut plywood to its required size, whereas I use a circular saw in my driveway to break down plywood to a smaller size so I can bring it to my workshop.

Related: My 12×13 Small Woodshop Layout

Ease of Use

Table saws are ready to go right out of the box and generally are easier to use than circular saws.

This is because table saws have a rip fence, making it easier to make long, straight cuts. You can also make repeatable cuts with a rip fence, meaning you set the fence once and make identical cuts on multiple pieces of wood.

Circular saws, on the other hand, require you to guide them along the line you wish to cut. Using a circular saw freehand can be difficult and usually takes some practice and skill to get the hang of it. You can use an optional straightedge with a circular saw, making them easier to use.

Versatility

Circular saws have a slight advantage over table saws when it comes to versatility.

Table saws are limited to making rip cuts, crosscuts, bevel, and miter cuts in materials such as wood and plywood.

Circular saws, on the other hand, can make all of those same cuts, plus they can make compound cuts and plunge cuts. In addition to wood and plywood, with the right blade, circular saws can also cut through metal, tile, brick, and concrete.

Accuracy

When it comes to precision, table saws are the clear winner. Thanks to their rip fence, table saws can make long, straight cuts with ease. Circular saws don’t have a rip fence, but you can use an optional straightedge or accessories to improve their accuracy.

Safety

Table saws can be very dangerous if they’re not used properly. Circular saws can also be dangerous, but they’re generally considered safer than table saws.

If you’re using either type of saw, it’s important that you read the instructions carefully and take the necessary safety precautions.

Cost

Table saws are larger than circular saws, and as a result, they generally cost more. You can usually find basic table saws for less than $200, whereas basic circular saws are usually less than $50.

Which is the Right Saw for You?

Now that you know the difference between table saws and circular saws, which one is the right choice for you?

Table saws are great for making long, straight cuts in wood and plywood. If you need to make a lot of identical cuts, table saws are also an excellent choice.

Circular saws are more versatile because they can make compound cuts, plunge cuts, and cut other materials such as metal and concrete that table saws can’t. Circular saws may be used either freehand or with optional accessories or a straightedge. However, table saws are generally more precise than circular saws.

That said, many times, you’ll want both a table saw, and a circular saw. It can be dangerous to cut full sheets, or large pieces of plywood on a table saw. I frequently use a circular saw to break down plywood into more manageable-sized pieces and then cut those pieces to the required size with my table saw.

When it comes to safety, table saws can be very dangerous if they’re not used properly. Circular saws can also be dangerous, but they’re generally considered safer than table saws.

If you’re just starting out, or if you’re on a budget, a circular saw is a great choice. If you have the money and the space, though, a table saw is worth the investment. Either way, it’s important to consider the projects you want to accomplish and choose the saw that’s best for your needs.

Frequently Asked Questions

Which is better a circular saw or a table saw?

There is no definitive answer to this question because it depends on your needs. Table saws are heavy and typically used in a workshop, while circular saws are more portable.

Table saws and circular saws both make rip cuts, crosscuts, bevel cuts, and miter cuts, but if you need to make a lot of identical cuts, a table saw is an excellent choice.

Circular saws are more versatile because they can make compound cuts, plunge cuts, and cut other materials such as metal and concrete that table saws can’t.

So which is better depends on if you need a tool that is portable or not, the type of cuts you need to make, and the type of material you need to cut.

Can I use a circular saw as a table saw?

A circular saw can be used for the same tasks as a table saw, but it lacks a fence. A table saw’s fence guides the material being cut, providing greater precision than a circular saw. However, you can use a straightedge or accessories with your circular saw to help improve its accuracy.

Do you need a circular saw and a table saw?

You might need both table saw and circular saw. For example, it can be dangerous to cut larger pieces of plywood or full sheets on a table saw so you can use a circular saw to break them down into more manageable sizes. Then you can use the table saw for making more precise cuts.

Another reason you might want both is that a circular saw is more portable than a table saw so it can be used for tasks where you need to take the saw to the material, such working on a project in the backyard.

Final Thoughts

As you can see, table saws and circular saws both have their own unique set of features that make them each ideal for different tasks. When choosing which saw to buy, it’s important to consider what types of cuts you’ll need to make and what materials you’ll be cutting.

A circular saw is a great option if you’re just getting started or on a budget. If you have the space, a table saw is worth the investment, and for certain tasks, you may find that you’ll want both saws.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!