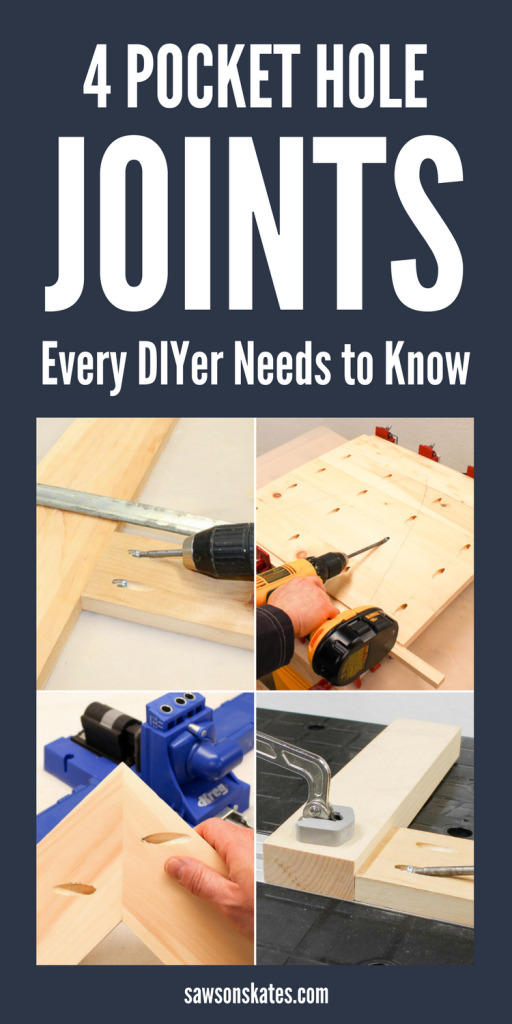

Common Pocket Hole Joints Every DIYer Should Know

Your Kreg Jig is probably one of the tools you use the most, but did you know there are four common pocket hole joints? Let’s review the joints, learn how to make each joint and how to use the joints for building DIY projects.

You may also enjoy these 9 Solutions to Common Pocket Hole Problems.

There are four common pocket hole joints we use to build our projects. Those joints include butt joints, edge joints, miter joints and joining different thickness. Today we’ll look at each of these joints, the proper techniques for assembling each joint, and how to use them for building DIY furniture projects.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

Common Pocket Hole Joints Every DIYer Should Know

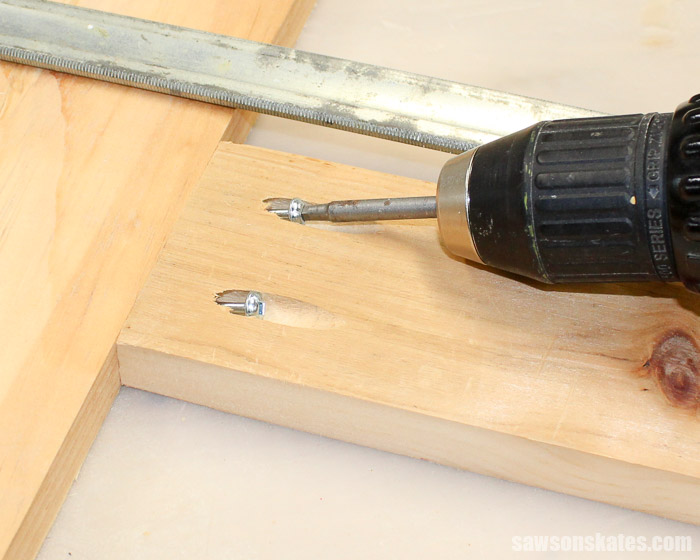

Before we look at the common pocket hole joints we should first answer the question “what is pocket hole joinery?” A pocket hole jig, like a Kreg Jig, uses a drill guide with preset holes to drill angled pocket holes into a workpiece. A pocket screw, specifically designed to be used with pocket holes draws two workpieces together to form a strong joint.

There are a variety of Kreg Jigs available for a range of budgets and quantity of pocket holes that need to be drilled. The most economical option is the Kreg Jig Mini. The Mini is great for making repairs and for projects where only a few pocket holes are needed. Skate over to this post for an easy to follow Kreg Jig Mini tutorial and video. If you need to drill lots of pocket holes or own a cabinet shop, etc. the Kreg Foreman is a great option.

I started building with the Kreg Jig K3 but recently upgraded to the Kreg Jig K5. For more info about why I’m digging the K5 skate over to 5 Reasons Why the Kreg Jig K5 Will Change the Way You Make Pocket Holes.

Butt Joint

I think the most common joint we make with the Kreg Jig is a butt joint. A butt joint joins the end of one workpiece to the edge of another workpiece. Common uses for butt joints are for creating frames, making furniture assemblies, and building doors.

I used butt joints to make furniture projects like the side assembly of this bathroom vanity, the top of this outdoor coffee table, and home improvement projects like this screen door and this interior door.

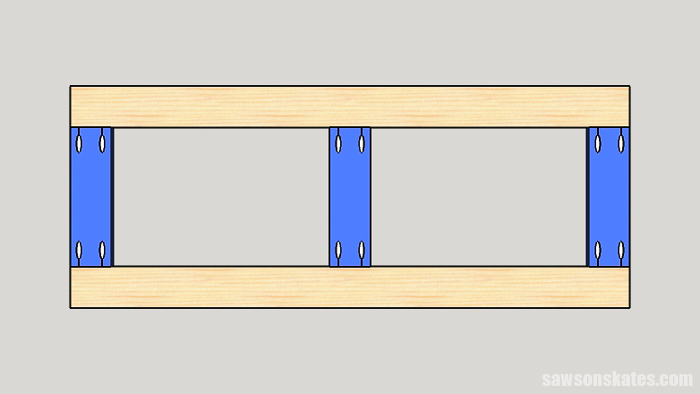

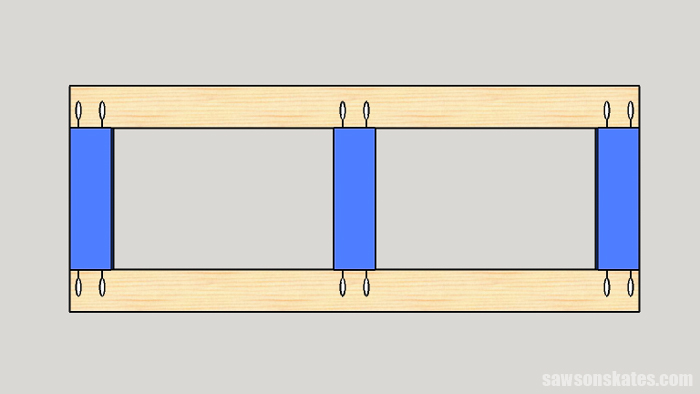

DO: When making a butt joint drill the pocket holes into the ends of the workpiece. Let’s say we are going to build a door. The pocket holes need to be drilled into the vertical (blue) pieces, not the horizontal (wood grain) pieces.

DON’T: When making a butt joint do not drill pocket holes into the edge of a workpiece (horizontal wood grain piece). This would not create a strong joint. The grain of the wood runs the length of the board. The end of the board is referred to as end grain.

Think of the wood grain or wood fibers like a box of drinking straws. Imagine driving a screw into the end of a box of drinking straws. What would happen to the screw? That’s right, it would just spin around in the ends of the straws. Driving screws into end grain does not create a strong joint.

Edge Joint

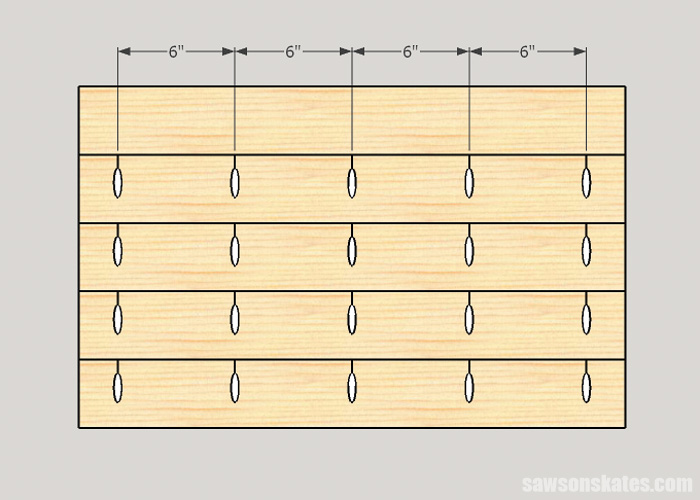

An edge joint is probably the second most common joint we use when building our DIY furniture projects. An edge joint joins the edges of boards to form a wider piece. Common uses for edge joints are to make panels and table tops. I used edge joints to make furniture projects like the back panel of this wall-mounted wine bar.

Related: DIY Farmhouse Table Top

How far should we space the pocket holes from the edge of the board? How far apart should we space pocket holes along the edge? Should we use glue when assembling edge joints? Should we use clamps when assembling edge joints? For answers to all of these questions skate over Need to Know Pocket Hole Tips for Edge Joints.

Miter Joint

A mitered corner or miter joint can add a decorative element to picture frames, doors, and DIY furniture projects. Drilling pocket holes on miter joints is easy, but it does take a little extra thought and planning. We need to pay attention so we don’t accidentally drill through the edge of our workpiece.

For miter joint tips and three options for assembling miter joints with pocket holes skate over to Drilling Pocket Holes on Miter Joints Requires Careful Planning.

Different Thicknesses

Joining materials of the same thickness with pocket holes is straightforward, but joining different thicknesses with pocket holes can be a little confusing. How should we set up our Kreg Jig to join thicker and thinner materials? What length screw should we use?

There’s a simple “rule” to remember when joining different thicknesses and that rule is “Think Thin”. Skate over to The Simple Rule for Joining Different Thicknesses with Pocket Holes to learn how to put the rule to use, see how to set up your Kreg Jig and learn the length of screw to use when joining different thicknesses.

FREE Pocket Hole Mistakes Guide

Master your pocket hole projects with this FREE ten-page Pocket Hole Mistakes You Don’t Want to Make Guide! The guide is overflowing with useful hints and easy tips to help you avoid time-consuming mistakes. Click below, get your FREE guide, and tackle your next pocket hole project with confidence!

Final Thoughts

There are four common pocket hole joints DIYers use to build their projects. Those joints include butt joints, edge joints, miter joints and joining different thickness. Each joint is a little different and requires a different technique for assembly.

Thank you for stopping by. If you found this information helpful, would you please pin it to Pinterest? Other DIYers would appreciate it and I would too! Thank you – Scott