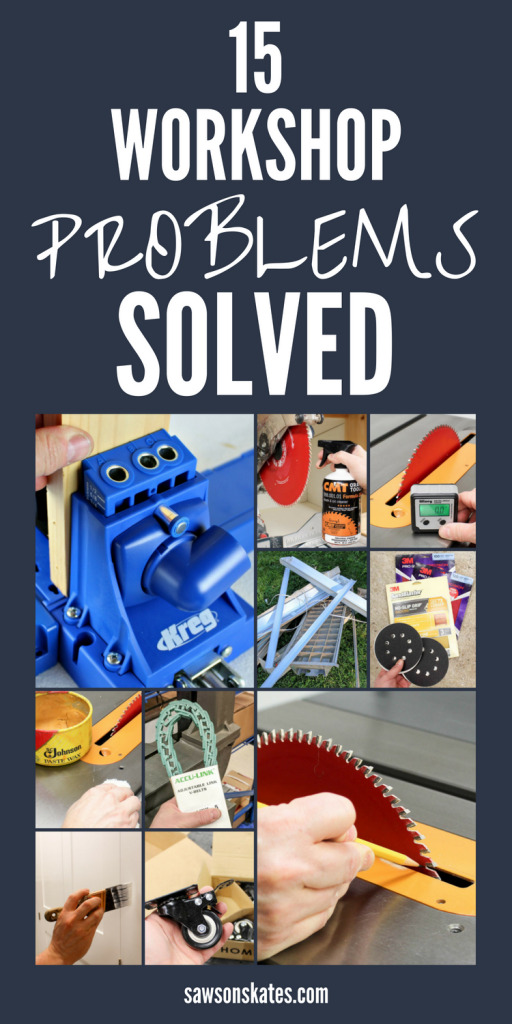

15 Easy Solutions to Common Workshop Problems

Common workshop problems are unfortunately all too common. Here are 15 easy solutions you can start using in your workshop now.

As DIYers, we have to deal with common problems in our workshops. Couldn’t we all benefit from helpful ideas when it comes to improving, organizing and making our shops a more enjoyable place to work? Here are simple solutions to 15 common workshop problems you can start using in your workshop today.

This tutorial contains affiliate links to supplies and tools. Purchases made using these links help support the Saws on Skates website and allows me to share more projects and tips with you. There is no cost to you for using these links. Visit my site policies for more information.

15 Easy Solutions to Common Workshop Problems

1. PROBLEM: Your Workshop is Dark

One of the easiest ways to brighten up a dark workshop is with paint. Painting is relatively easy, paint is fairly inexpensive and makes an immediate impact. After I painted my workshop I wished I had done it sooner! Painting makes a small workshop feel bigger, brighter and more inviting.

Skate over to Paint Makes a Small Workshop Feel Bigger and Brighter to see which color and which sheen I recommend.

2. PROBLEM: Your Workshop is Still Dark

Are you’re still using dim fluorescent lights in your workshop? Then it’s time to make the switch to LED lights. LED lights are bright, there are no bulbs to change and unlike fluorescent lights, they turn on instantly. And did I mention LED lights are SUPER BRIGHT!

Skate over to Why I Replaced My Fluorescent Workshop Lights with LED Shop Lights to see the difference for yourself.

3. PROBLEM: You’re Confused About What Scrap Wood to Keep (and What to Toss)

Are you constantly asking yourself “should I keep this piece of scrap wood? Should I toss it?” You’re not alone. Oftentimes scrap wood piles up on our workbenches because we’re not sure what to do with it.

These piles slow down our progress when building DIY projects because we’re constantly moving cutoffs from one area of the shop to another. This “moving scrap wood game” not only slows down our progress, but it can create major safety issues in our workshops. What we need are some guidelines for dealing with scrap wood.

Skate over to How to Decide What Scrap Wood to Keep for the tips and tricks I use in my small workshop for deciding what scrap wood to keep and what to toss.

After we decide what scrap wood we’re going to keep we’ll need a place to store it. Skate over to 9 DIY Ideas for Wood Storage that perfect for storing wood in a small workshop.

4. PROBLEM: Your Miter Saw isn’t Properly Adjusted

Over time our miter saws can come out of adjustment and sometimes even new saws out of the box need some tweaks. Saws that aren’t adjusted properly can affect the quality of our cuts and can cause our joints to fit poorly. When was the last time you tuned up your miter saw?

Skate over to How to Adjust a Miter Saw for Accurate Cuts for the method I use to adjust my miter saw.

5. PROBLEM: Too Much Friction

It sounds crazy, but I wax my table saw and I think you should too. It’s not just to make our saws look pretty and shiny. Waxing makes our table saw easier to clean, reduces the chance of oxidation, and perhaps most importantly waxing reduces friction. Over time wood sliding across the table can leave behind wood pitch. The wood pitch can build up and cause friction. Then workpieces “stick” rather than slide across the table.

And wax isn’t just for our table saw. We can wax other shop equipment like our miter saw, bandsaw, thickness planer, jointer and more. Basically, any tool where wood is moving can benefit from wax.

Skate over to Wax Your Table Saw to Reduce Friction and Maximize Performance for a full tutorial, to see which wax I use and a how to video.

6. PROBLEM: Your Blade Angle isn’t Precisely Adjusted

I used to set my table saw blade angle manually with a speed square, but I never felt like the blade was adjusted as precisely as it could be. Then I discovered a digital angle gauge. A digital gauge takes the guesswork out of setting the angle and it allows us to precisely set our blades for any angle we choose.

Skate over to the Best Way to Set Table Saw Blade Angle for Precision Cuts for a full tutorial and a digital angle gauge video.

7. PROBLEM: You’re Tools Take up too Much Space

Making our tools mobile is one of the best ways for us to maximize space in our small workshops. Roll it out when you need it and roll it back when you don’t. Making tools mobile is the reason I named this blog “Saws on Skates”! If I can’t put it on wheels it doesn’t go in my tiny workshop.

Skate over to 7 Ideas to Make Your Tools Mobile & Maximize Workshop Space for some clever ways to put your “saws on skates”.

8. PROBLEM: Your Sandpaper is Disorganized

My sandpaper was out of control. Sheets of sandpaper mixed with sanding discs, 150 grit mixed with 60 grit and sandpaper flying out of my workshop cabinet when I opened the door. Then I discovered a weird, but effective way to store sandpaper in my small workshop.

This storage method not only organizes the sandpaper but makes it easy for us to take an assortment of sandpaper with us when we’re DIYing outside in the yard or hit the road for a DIY project at a buddy’s house. Here’s a hint, you won’t find this storage option in a hardware store.

Skate over to see the unusual way I store my sandpaper.

9. PROBLEM: Your Dull Saw Blade May Actually be Dirty

Over time wood can leave deposits on our saw blades. Cleaning our saw blades improves the quality of our cuts, reduces the chance corrosion and keeps our tools running at peak performance. Not only that, but some saw blades that are thought to be dull just need a good cleaning. Is your blade really dull or does it just need to be cleaned?

Skate over to Clean Saw Blades for Peak Performance and Quality Cuts to see the product I use to clean my blades and how easy it is to clean a saw blade.

10. PROBLEM: You’re Making Pocket Hole Mistakes

I use my Kreg Jig to build nearly every furniture project and I’m even using my Kreg Jig to build my “Skate-Away” DIY Truck Camper. A pocket hole jig is really easy to use, but still, mistakes can be made and I’ve made them all!

Skate over to 9 Pocket Holes Mistakes You Don’t Want to Make to avoid the mistakes I’ve already made and grab your FREE 9 Pocket Holes Mistakes You Don’t Want to Make Guide!

11. PROBLEM: Your Clamps are Piling Up

You know what they say about clamps. We can never have enough! But we need a way to store them otherwise those useful clamps can just get in the way. And no, piling clamps on a workbench is not considered storing them!

Skate over to 7 Clever Clamp Storage Ideas for a Small Workshop for some great options for storing clamps. For clamping, hints and tricks skate over to 6 Tips to Clamp Your DIY Project Like a Pro.

12. PROBLEM: You Need Some Proper Workshop Furniture

It’s difficult to DIY without some proper workshop furniture. And oversized shop furniture in a small workshop just doesn’t work. Building space-saving workshop furniture is one of the best ways to make the most of our small workshops. Here are my favorite workshop furniture projects:

- Build a DIY Folding Workbench

- Build a DIY Flip-Top Workbench Cart and see how the cart is holding up two years later.

- Build the Ultimate Workbench for a Small Workshop

- Build a DIY Miter Saw Station

13. PROBLEM: You’re Not Making the Most of Your Miter Saw

A miter saw without a doubt is the saw I use the most for building my DIY projects and there are a few miter saw tricks I think every DIYer should know about. Tricks like why you should “leave the line”, why you should let the blade come to a full stop, how to use the blade to make micro adjustments and more.

Skate over to 7 Miter Saw Tricks Every DIYer Should Know to see my favorite miter saw tips and tricks.

14. PROBLEM: You Can’t Easily Start/Stop Your Shop Equipment

This idea was sent to me by Saws on Skates community member Barry of New Jersey. Barry also let me “borrow” a pic of his workshop for the 9 Clever Ideas to Make Your Small Workshop Feel Bigger post.

I haven’t tried this Indoor Wireless Remote Control Kit yet, but Barry tells me that he has his “wall vent fan, compressor and remote ShopVac on this. And they all work great!” This remote control kit seems like a great solution for those hard-to-reach power switches. It’s also great when you’re across the shop and you want to turn on a tool like, as Barry mentioned, a compressor. This kit is definitely on my workshop wish list!

15. PROBLEM: Your Shop Equipment Vibrates Like Jack Hammer

Does your table saw, bandsaw, drill press or sander use a v-belt? Have you heard of an adjustable link belt? An adjustable link belt can be used on just about any woodworking tool, it’s easy to install and helps to reduce vibration in our woodworking tools.

Skate over to What You Need to Know Before You Buy an Adjustable Link Belt for your woodworking tools.