How to Get into Woodworking Without a Table Saw

Think you need a table saw to get into woodworking? You don’t! Start building today with this list of tools you can use instead.

Don’t have a table saw? No problem! There are plenty of other tools you can use instead to build beautiful woodworking projects. In this article, we will discuss the best ways to get the job done without a table saw. Stay tuned, and you’ll be on your way to creating amazing pieces in no time!

Table of Contents

- What is a Table Saw?

- What are the Reasons for Not Owning a Table Saw?

- Types of Cuts

- How to Rip Cut Without a Table Saw

- How to Crosscut Without a Table Saw

- How to Make Miter Cuts Without a Table Saw

- How to Make Bevel Cuts Without a Table Saw

- How to Make Dados, Grooves, and Rabbets Without a Table Saw

- How to Make Joinery Cuts Without a Table Saw

- Chart: Cuts and Alternate Tools You Can Use

This article contains affiliate links. If you purchase from these links, I may earn a small commission at no additional cost to you. Visit my site policies for more information.

What is a Table Saw?

A table saw is a power tool used to cut wood. It consists of a circular blade mounted beneath a flat work surface called the table within an opening called the throat plate. The cutting depth and angle can be adjusted by raising, lowering, or tilting the blade.

Related: Best Way to Set Table Saw Angle

A rip fence is frequently used with a table saw to help guide the material while it’s being cut. The operator stands in front of the machine and pushes the workpiece along the fence towards the blade to make a cut.

One advantage of a table saw over other saws is its large work surface, allowing it to accommodate materials such as plywood sheets.

However, a table saw is large and bulky, making it less portable than other saws. Because of its size and weight, you’ll likely need a dedicated space for one in your workshop or garage.

Related: 9 Ways to Get Into Woodworking Without a Garage

What are the Reasons for Not Owning a Table Saw?

Though a table saw is a useful tool for many projects, not everyone owns one for several reasons, including size, cost, and safety concerns.

Table saws can take up a lot of room, so they may not fit into your workshop if space is limited.

Related: 9 Clever Ways to Make Your Small Workshop Feel Bigger

The cost of a table saw can range anywhere from $250 to more than $3,000, which is an investment that some woodworkers are not ready to make.

Finally, table saws can be extremely dangerous. Every year, thousands of people are injured by them, and many of these injuries are severe.

Related: 21 Table Saw Safety Rules (& Mistakes to Avoid)

No matter the reason, you can use plenty of other tools instead of a table saw to build woodworking projects.

Before deciding which tool to use, you’ll need to determine the types of cuts necessary for your project. Let’s look at those next.

Types of Cuts

Knowing the types of cuts you need to make is key when searching for a table saw alternative. With that in mind, let’s review the cuts that can be made with a table saw and then explore other ways to make those same cuts. Or, if you already have some tools on hand, check out the chart below to see if they’ll work for your project.

Rip Cut

To make a rip cut, set your saw blade to 90 degrees, then cut along the length of your workpiece.

Rip cuts are often used to make a board narrower or to break down plywood sheets to the dimensions needed for building cabinets or furniture.

Related: How to Make DIY Cabinet Doors

Bevel Cut

To make a bevel cut, adjust your saw blade to an angle other than 90 degrees, then cut along the length of your workpiece.

Bevels are frequently used to make french cleats, a hanging system ideal for organizing tools or attaching wall-mounted cabinets.

Related: How to Make a French Cleat

Crosscut

To make a crosscut, set your blade to 90 degrees, then cut across the width of your workpiece. Crosscuts are frequently used to cut boards to their required length.

Miter Cut

To make a miter cut, set your saw blade to an angle other than 90 degrees, then cut across the width of your workpiece. Miter cuts are often used to cut molding, trim, and picture frame parts to their desired length.

Dados, Grooves, and Rabbets

A table saw can be fitted with a dado blade, which is usually multiple blades stacked together that act as one wide blade. Dado blades are primarily used in woodworking to cut dados, grooves, and rabbets, which carve out a small space where you can join two pieces of material together.

- Dados aremade across the width of workpieces.

- Grooves are made along the length of workpieces.

- Rabbets are made along the edge of workpieces.

How to Rip Cut Without a Table Saw

If you don’t have a table saw, there are several options to make accurate rip cuts.

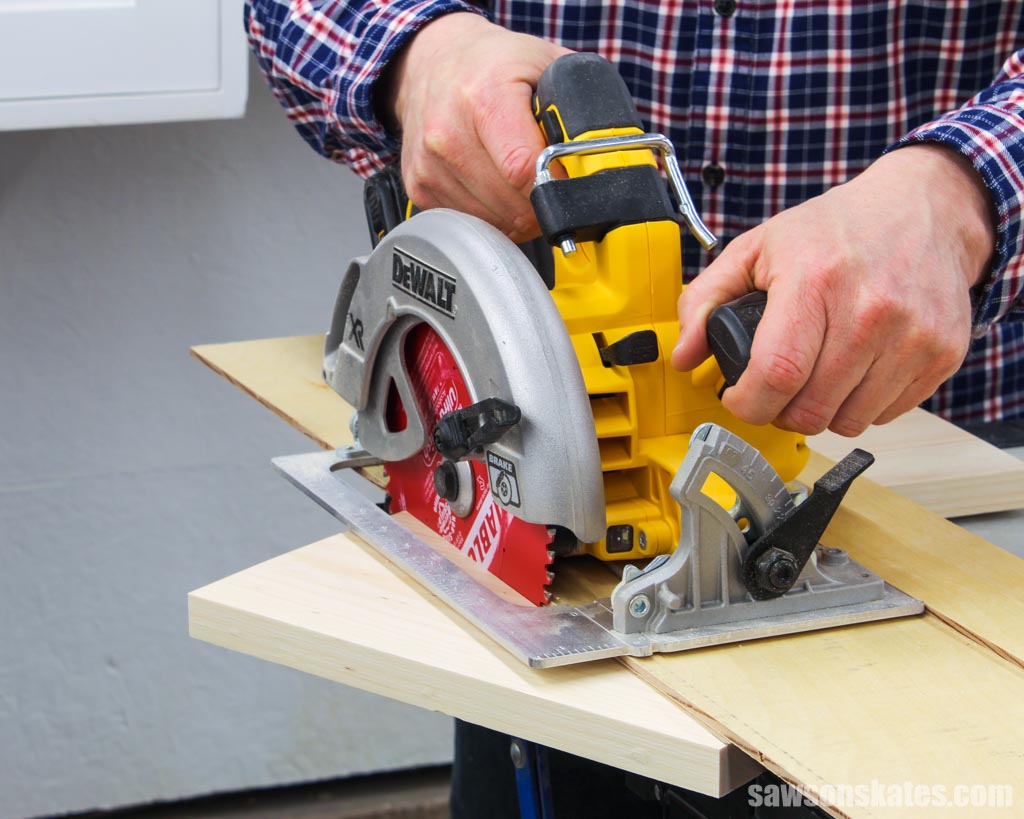

Circular Saw

A circular saw is an effective way to make rip cuts without a table saw. They’re best suited for ripping sheet goods, such as plywood and MDF.

Related: Table Saw vs Circular Saw (Which Should You Buy?)

You can use a circular saw freehand, but for the most accurate result, it’s best to use it with a guide.

Using a guide will provide you with a straight line to follow as you move the saw along the length of your workpiece.

Related: 4 Ways to Make Straight Cuts with a Circular Saw

You can use anything from a long, straight board or a store-bought straight edge, such as the Kreg Straightedge Guide or the BORA Straight Cut Guide.

Related: Kreg Straight Edge Guide (How to Use and Review)

You can also use an accessory like the Kreg Rip-Cut which attaches to your saw and follows the edge of your workpiece.

The advantage is you can set the guide once and make repeatable cuts. But the drawback is the edge of your workpiece needs to be straight to begin with; otherwise, the cut will be inaccurate. Also, it’s limited to making cuts up to 24 inches wide.

Track Saw

Another option for making rip cuts is a track saw which is essentially a circular saw that rides along a guide rail. The advantage is the guide rail keeps your saw on course and ensures straight, precise cuts.

The drawback is they can be expensive and the guide rails can be cumbersome to store in your shop.

Band Saw

A band saw is also a good option for making rip cuts. Because of their small work surface; however, they’re best suited for making rip cuts on boards rather than sheet goods.

The drawback to using a band saw is the blade can sometimes wander, resulting in an inaccurate cut. Another downside is that band saw blades leave the edge of your workpiece rougher than a table saw or circular saw, so you’ll need to do some sanding to smooth it.

Related: 11 Secrets for Sanding Wood Projects Like a Pro

Jigsaw

Another tool that can make rip cuts is a jigsaw. Using a jigsaw won’t be as precise as using a circular saw or track saw, so only consider it when accuracy isn’t as important.

One way to improve accuracy is to use a guide like the Kreg Straightedge Guide, which will ensure your saw follows your cut line. However, a jigsaw’s blade can flex from top to bottom, resulting in the edge of the cut not being square.

How to Crosscut Without a Table Saw

Crosscuts are often made with a table saw using a miter gauge or crosscut sled, but there are other tools you can use to make accurate crosscuts.

Handsaw and Miter Box

The simplest way to make crosscuts is with a handsaw and miter box.

A miter box is an easy-to-use tool that consists of a base and two grooved sides. The workpiece rests in the bottom of the box and the grooves guide the handsaw as the workpiece is being cut.

Miter boxes are ideal for people with limited space or tight budgets and for anyone hesitant to use power tools.

Miter Saw

Another option for making crosscuts is a miter saw. Miter saws have a blade on a pivoting arm that can be rotated right to left and tilted top to bottom.

My go-to tool for making crosscuts is a miter saw. When I need several boards cut to the same length, I use a stop block to ensure consistency. A stop block clamps to your saw’s fence and ensures all of your workpieces are cut to the same length.

Circular Saw

Circular saws can also be used to make crosscuts. You can make the cut freehand, but you can also use a speed square or crosscut guide to improve the accuracy.

Band Saw

Band saws can be used to make crosscuts, but the drawback is they have a small work surface, so they’re not ideal for making crosscuts on long workpieces.

Jigsaw

Although you can use jigsaws to make crosscuts, they aren’t as precise as miter saws or circular saws. Only consider using a jigsaw when accuracy won’t impact the quality of your project.

You can use a speed square as a fence to make more accurate cuts. While this method will produce a straight crosscut, the blade can flex, making it difficult to produce a square cut from top to bottom, especially when working with thicker boards.

How to Make Miter Cuts Without a Table Saw

Miter cuts are often made with a table saw using a miter gauge or a sled, but there are other ways of making accurate miters without a table saw.

Handsaw and Miter Box

The simplest way to make miter cuts is with a handsaw and miter box. As I mentioned above, miter boxes have grooved sides; most have presets for 45°, while some have presets for other common miter angles. The drawback is you’re limited to the presets, so you can’t make other angles.

Miter Saw

Miter saws are the best tools for making miter cuts. They’re more accurate than a miter box and not limited to preset angles, so you can adjust them to almost any angle you need for your project.

Circular Saw

Circular saws can be used to make miter cuts, although they won’t be as precise as using a miter saw. To improve the accuracy of your miters, use a speed square or straightedge.

Related: Miter Saw vs Circular Saw (Differences + Which to Choose)

Jigsaw

Jigsaws can also be used to make miter cuts, although they won’t produce as accurate cuts as a miter saw. Be sure to use a speed square for more precision, and keep in mind the blade can flex, creating a cut that’s not square from top to bottom.

How to Make Bevel Cuts Without a Table Saw

Bevel cuts are often made with a table saw using either the fence or miter gauge, but there are other methods to make bevels without a table saw.

Miter Saw

You can use a miter saw to make bevel cuts on the ends of boards, but it’s not capable of making them along the length of a board.

Related: Single vs Double Bevel Miter Saw (Which to Buy & Why)

Circular Saw

Circular saws can be used to make bevel cuts on the end of a board or along its length. To ensure accuracy, use a speed square or straightedge guide to help you make the cut.

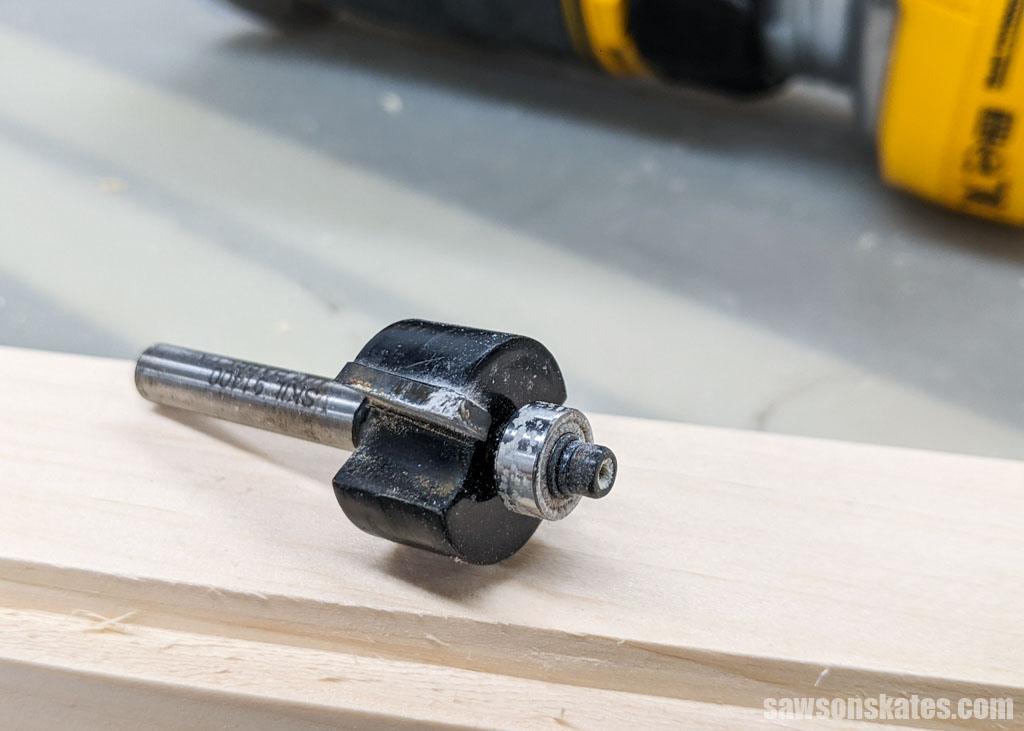

Router

To make bevels, you can use a router and a chamfer bit. A chamfered edge is a sloped corner between two sides of an object.

However, circular saws have the upper hand over routers when making bevels. With a circular saw, you can select practically any angle, while a router is limited to the angle of chamfer bits available to purchase.

Related: How to Use a Router Table for Beginners

Band Saw

Band saws can also make bevel cuts by tilting the table to the desired angle.

Jigsaw

Although a jigsaw’s baseplate can be tilted to make bevel cuts, it’s not as accurate or precise as a miter saw, circular saw, router, or band saw.

How to Make Dados, Grooves, and Rabbets Without a Table Saw

Dados, grooves, and rabbets are often made with a table saw using a dado blade, but you can use other tools and techniques to make these cuts.

Handheld Router

A handheld router and straight bit can be used to make dados, grooves, and rabbets.

You can improve the accuracy of your dados and grooves by using a straight edge or jig attached to the workpiece, and you can attach a fence to the router’s base plate to make rabbets.

You can also make rabbets using a rabbeting bit with a bearing that follows the edge of your workpiece. For example, I used a rabbeting bit when I made this DIY picture frame.

Router Table

Similar to a handheld router, you can use a router table and router bits to make dados, grooves, and rabbets.

How to Make Joinery Cuts Without a Table Saw

Joinery is the process of joining two pieces of wood together. Common joints are mortise and tenons, half laps, box joints, and splines.

Tenons

A mortise and tenon is a woodworking joint used to connect two pieces of wood together. The mortise (or “socket”) is cut into one piece of wood and the tenon (or “tongue”) is cut into the other, with both pieces fitting together to form a strong and durable connection.

Table saws are often used to cut tenons, but you can also use other tools to make these cuts.

Band Saw

Band saws are a great alternative to table saws for cutting tenons. Adjust the fence to the thickness of your tenon and slowly guide the workpiece through the blade.

Router Table

You can use a router table to cut the tenons and mortises.

Handsaw

You can use a handsaw to cut tenons; however, it can be more time-consuming than using a band saw or router table. It also requires patience and practice to get accurate cuts.

Half Lap

A half lap is a woodworking joint used to connect two pieces of wood at right angles. Half laps are often used to construct frames, cabinets, and other objects where strength and stability are important.

Router Table

A router table and a straight bit can be used to rout out the half laps.

Box Joint

A box joint is a type of interlocking joinery that connects two pieces of wood. It’s commonly used to construct boxes with strength and stability, such as jewelry boxes or drawers.

Related: How to Make Box Joints (3 Easy Ways)

To make box joints, you can use a jig, handheld router, or router table.

Spline

Splines are a great way to add extra strength and beauty to any joint. These thin pieces of wood or metal fit snugly into grooves, making them perfect for a variety of projects.

Router Table

A router table and a straight bit can be used to cut grooves for splines.

Chart: Cuts and Alternate Tools You Can Use

The chart below shows the tools you can use instead of a table saw to make woodworking cuts. Please refer to the corresponding sections to see which tool works best for each cut.

| CUT | ALTERNATE TOOL |

|---|---|

| Rip | Band Saw, Circular Saw, Jigsaw, Track Saw |

| Bevel | Band Saw, Circular Saw, Jigsaw, Miter Saw, Router |

| Crosscut | Band Saw, Circular Saw, Jigsaw, Miter Box, Miter Saw |

| Miter | Circular Saw, Jigsaw, Miter Box, Miter Saw |

| Dado | Router |

| Tenons | Band Saw, Hand Saw, Router |

| Half Lap | Router |

| Box Joint | Router |

| Spline | Router |

Final Thoughts

Table saws are amazing tools for woodworking, but they’re not essential to get into the hobby. If you don’t have a table saw, you can use several other tools to make accurate cuts, such as a circular saw, band saw, router table, and handheld router.

Interested in woodworking but need help figuring out where to start? Join our FREE Beginner Woodworker VIP List, and I’ll email you our 3 most popular beginner guides!

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!